Ashley Xrite Ci64 integrating sphere spectrophotometer

Product Details

Ci64 portable integrating sphere spectrophotometer - designed for reflective or uneven surfaces

Ashley portable integrating sphere spectrophotometer Ci64 has a large high-resolution color screen, a Graphical Jobs interface and configurable menus. Users can quickly and easily understand the color measurement program, maintain color consistency in the measurement process and quickly view the measurement data. The flip mechanism of the Ci64 integrating sphere colorimeter increases the flexibility of the instrument for measuring areas that are difficult to reach, and has a simple lock button to ensure that no errors occur during quality inspection. If the measured sample contains fluorescent whitening agent, UV option can also be added to ensure color accuracy.

Advantages of Aisele Ci64

Accurately measure reflective or uneven surfaces of various products and packaging types, or materials containing optical brighteners.

Audit and track color quality of multiple equipment and locations to ensure color consistency and brand integrity in the supply chain.

Up to 4000 reference samples can be stored for quick access to existing data.

When the optional charger is used to charge the second battery, the Ci64 portable spectrophotometer can be used normally without interruption to extend the operation time of the instrument.

Measurement jobs can be determined and optimized remotely through NetProfiler, and users can improve measurement performance by applying corrections regardless of whether a PC is connected.

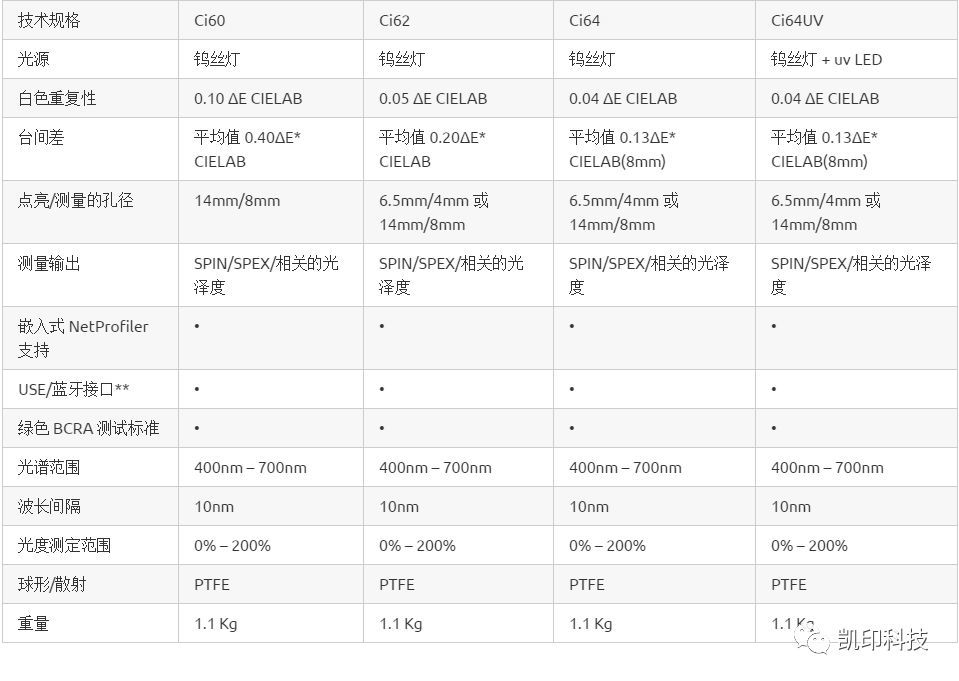

Aisele portable integrating sphere spectrophotometer Ci64 has three specifications and models, all of which support synchronous SPIN/SPEX output and relevant glossiness measurement, and has the embedded NetProfiler function. The three specifications are:

Ci64, with a switchable 4mm and 8mm measuring aperture;

Ci64L, with a measuring aperture of 14mm for measuring larger samples;

Ci64UV with a switchable 4mm and 8mm measuring aperture and tungsten and UV LED lighting.

Functional differences between different versions

The remote measurement trigger allows the operator to initiate hands-free measurement and supports USB and Bluetooth * *.

**Applicable countries and regions: EU, USA, Canada, China, Taiwan, China, India, Japan, South Korea

Ci64 series portable integrating sphere spectrophotometer can help enterprises solve the problem of color inconsistency between customer specifications, final products and batches, thus improving profitability. We often encounter that customers use more metal colors, special effects and textures to achieve the uniqueness of products, making them more competitive and attractive, but at the same time, the cost will be more expensive.

In order to reduce waste and rework, consistent color monitoring and an effective quality control plan are necessary. Azeri Ci64 series portable integrating sphere spectrophotometer is widely applicable to a wide range of materials. It can audit and track across devices and locations, effectively helping you to ensure the color consistency and accuracy in the work process.

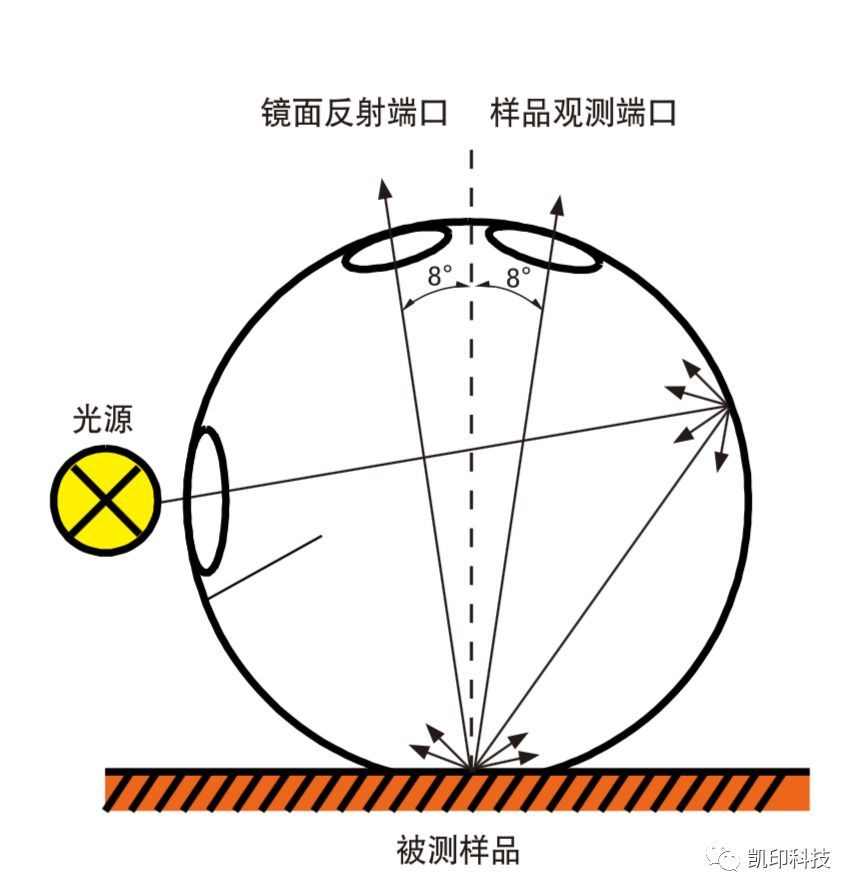

Measuring principle of ASELI CI64 integrating sphere spectrophotometer

As shown in the figure, the working principle of the 8 degree scattering integrating sphere instrument is described.

The integrating sphere instrument can provide reflectivity measurement data in two ways, including specular reflection and exclusion of specular reflection (also called first surface reflection). The specular reflection measurement excludes specular or glossy components. The integrating sphere instrument has a specular reflection port that, when opened, allows the specular reflection component to overflow, providing data containing specular reflection. If the surface with texture structure, rough surface, irregular surface or near bright mirror surface is to be measured, the integrating sphere instrument shall be selected. This kind of instrument is commonly used for gold and silver paperboard measurement, metal surface measurement, and black ink system. It is also widely used in cigarette package printing, commodity packaging, and high-end cosmetics packaging and printing.

Common problems and solutions of Ashley Xrite Ci6X series

1、 Ci6x white correction display correction error, correction failed.

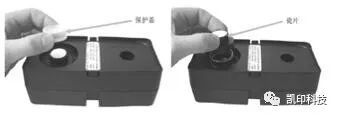

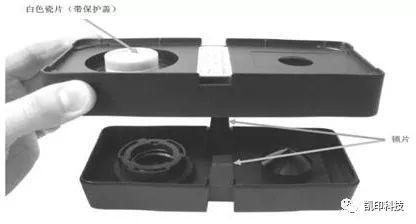

1. Clean calibration reference

a. Remove the plastic protective cover from the porcelain. Always hold the edges of the tiles and be careful not to touch the white surface. Press the ceramic tile down and turn it counterclockwise until it can no longer turn. Lift up the porcelain piece and remove it from the base.

b. Clean the tiles with mild soap and warm water. Rinse thoroughly with warm water and dry with a lint free cloth. Do not use any kind of solvent or cleaning agent. After the tiles are completely dry, align the big tabs on the edges of the tiles with the big grooves on the base. Press the spring down through the porcelain piece until it can no longer be pressed down. Press and hold the porcelain piece, and rotate it clockwise until it can no longer rotate. Slowly let the tiles rise. When correctly placed, the arrows on the tiles should be aligned with the arrows on the base. When the porcelain piece is not used, reinstall the protective cover on the porcelain piece.

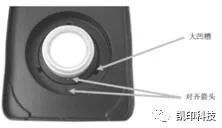

c. Clean the black cylinder. Press the two locking tabs on both sides with your fingers to separate them to split the two parts. Clean with clean, dry air or remove dust or dirt with a lint free cloth. After cleaning, align the two arrows at the ends before reassembling each component.

d. After cleaning the calibration reference, carry out the calibration operation. If the calibration is still unable, carry out Operation 2 (restore the factory settings)

2. Restore factory settings

Go to the last option in the instrument configuration menu, click "Confirm" to restore the factory settings, and then try to correct. If the correction is still not possible, execute Operation 3 (Update Firmware). (After the factory settings are restored, all data will be cleared. If you do not want to clear the data, please directly perform operation 3)

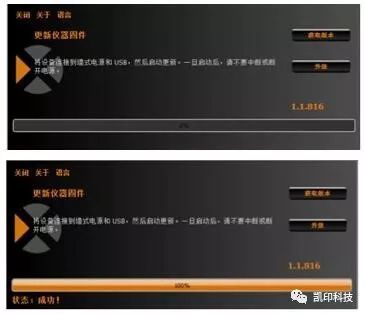

3. Update firmware to 1.1.816

a. Download the latest firmware Ci6X Firmware r1.1.816. The download link is as follows: http://www.xrite.com/service-support/downloads/C/Ci6X-Firmware-r1_1_816

b. After downloading, double click to open the firmware, ensure that the Ci6x is connected to the wall power supply and connected to the computer through the USB cable, and then click Upgrade until the upgrade is completed, indicating success.

Ci6x Latest Firmware Version 1.1.816 Application Notes

Note: This function has a good effect on the instrument with "incorrect whiteboard value" prompt during white correction. For the instrument with the prompt of "light source failure", please try to clean it first. If the error prompt changes to "incorrect whiteboard value", then try to repair it, but the success rate is not as high as that of the instrument with the previous phenomenon.

After the firmware is successfully upgraded, it is recommended to clean the optical components of the instrument before white correction. Please ensure the following:

1. The surface of white correction plate is clean;

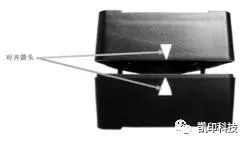

2. The contact surface between the target window and the whiteboard is clean;

3. The target window has no displacement, and the circular hole in the middle of the 4mm target window and the circular hole of the instrument integrating sphere remain concentric; The middle circular hole of the 8mm and 14mm target windows coincides with the circular hole of the integrating sphere, and no edge is exposed in the circular hole of the integrating sphere.

4. The interior of the sphere shall be as clean as possible;

5. Ensure that the two pads at the back of the black base plate of the instrument are complete and the instrument is placed stably;

Recovery operation for whiteboard calibration failure:

1. Calibrate the instrument according to the normal steps,

2. When measuring the white correction sheet, the instrument still displays the prompt of "incorrect whiteboard value".

3. At this time, return to the main interface and perform another correction operation,

4. Normally, the instrument can pass the white correction.

If it still cannot be corrected, please contact us.

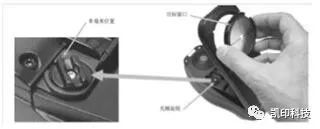

2、 Ci64 cannot be corrected after switching aperture

Make sure that the aperture is switched accurately. When switching the size aperture of Ci64, first turn the bottom knob, and then change the target window

In addition, after switching, the display on the screen is different, and then correct it.

3、 After the Ci64 completes the Netprofiler and succeeds, it displays the unconfigured or invalid configuration

After the Ci64 8mm aperture completes the Netprofiler, when switching to 4mm for use, you need to do the Netprofiler again for 4mm. 4mm and 8mm aperture have their own profiles.

4、 Ci6x fails to boot

First, ensure that the instrument is powered or connected to the wall power supply. If it still cannot be started, perform the factory reset and firmware update in Article 1. After the update, we still can't boot up. Please contact us.

5、 Ci6x screen "crashes"

First, check whether the instrument is locked. If it is locked, press the power button to unlock it. If the screen still cannot be controlled, restart the instrument and try again. If the problem still exists, execute the factory reset and firmware update in Article 1. If the problem still exists after the update, please contact us.

6、 Crocodile prompt appears after instrument calibration

At this time, the light source intensity becomes weak, and the measurement can still be carried out, but it is better to replace the light source as soon as possible. You can contact us to replace the light source, not replace it by yourself.

xrite

the

and

to

of

is

instrument

be

it

with

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time