Digital printing color quality control system | IntelliTrax2 intelligent track scanning+PressSign score

Product Details

IntelliTrax2 Automatic Scanner - Print Shop Color Control

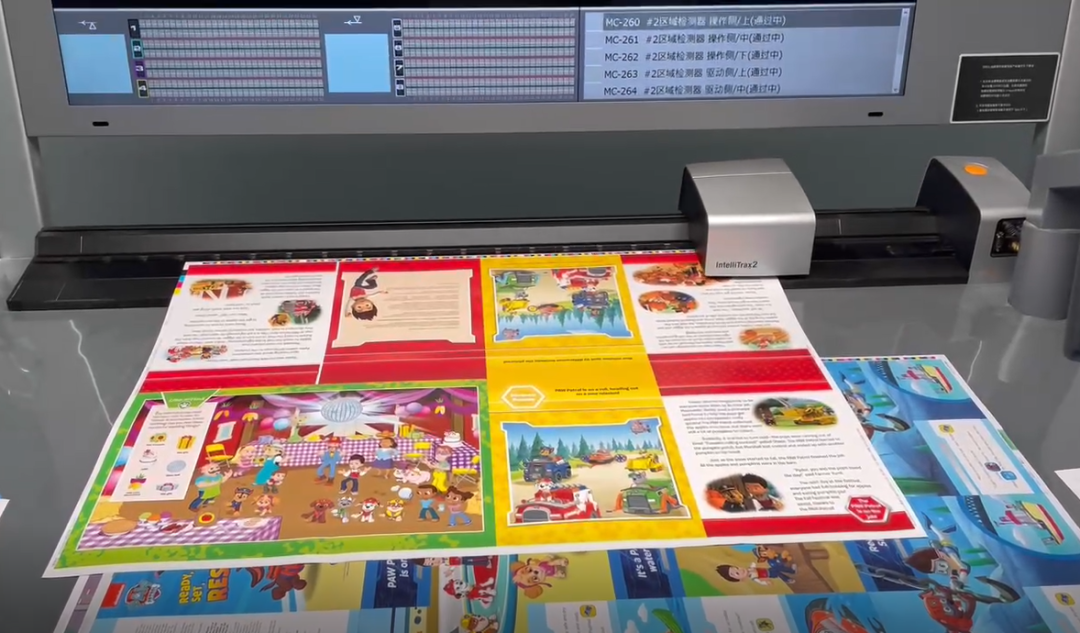

Super fast automatic printing on-site scanning solution

IntelliTrax2 comprehensive scanning solution can provide real-time operation performance feedback for large and medium-sized commercial and folding carton printers, improve quality control reports, achieve GMI/G7 printing specifications and create end-to-end interconnected printing shop workflow. Excellent printing field scanning solution.

Effectively reduce printing preparation time, improve printing efficiency, and easily realize printing standardization

It has passed the Idealliance G7 printing control system certification, supports PSO and ISO technical specifications, and can complete the work as required

As an overall color solution, prepress, printing machine operators and brands can be linked together to significantly improve the quality control plan

IntelliTrax2 Key Benefits

Super fast speed: IntelliTrax2 automatic color scanning/color measurement system can scan the ribbon on a typical sheet in 10 seconds.

Non contact instrument: do not worry about the image will appear stains or scratches in the color measurement process.

Equipped with suction device: the suction device is automatically opened during scanning, making the whole printing sheet smooth and stable for scanning and adapting to various complex environments.

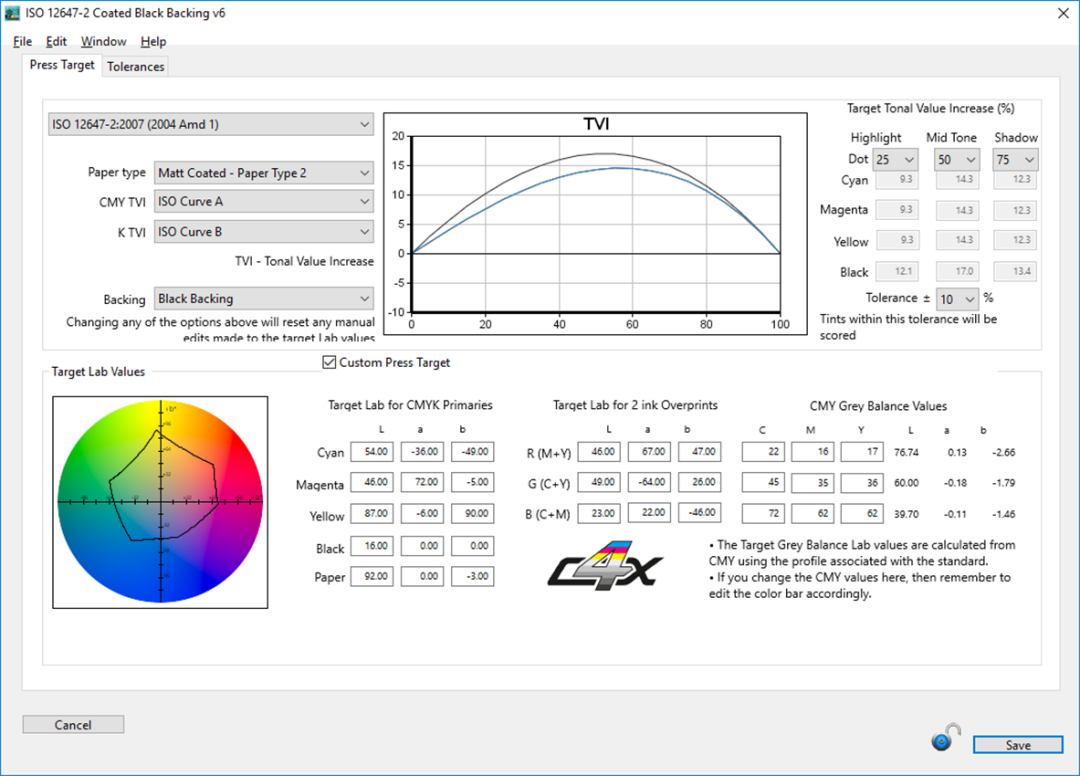

Support ICC color management industry standards: IntelliTrax2 automatic color scanning/color measurement system supports most of the global graphic art standards, including M1 for fluorescent whitening agent and M3 for measuring wet ink, and fully supports G7, PSO, GMI and FOGRA 51 and 52, and includes black backing as specified in ISO 12647-2 and 3.

The scanning head can be automatically adjusted: the advanced imaging technology adopted by IntelliTrax2 automatic color scanning/color measurement system can automatically adjust the scanning head to locate the color band, ensuring fast positioning and accurate measurement on each sheet.

Advanced automatic color management solution: IntelliTrax2 can be used for color printing of four or more colors, and can also measure CMYK+spot colors, PANTONE ® Color, non printing color and paper color are ideal for high-end, high-speed printing operations.

CIP4 and JDF industry data standards: IntelliTrax2 supports the use of CIP4 and JDF industry data standards, enabling faster settings and accurate work information (such as ink rotation, color specifications, work identification and paper material)

Best matching function: With its best matching function, IntelliTrax2 automatic color scanning/color measurement system will provide the operator with ink density suggestions according to the color difference between the target spectral information and the measured spectral information, so that the operator can quickly determine the satisfactory color matching on the printing machine.

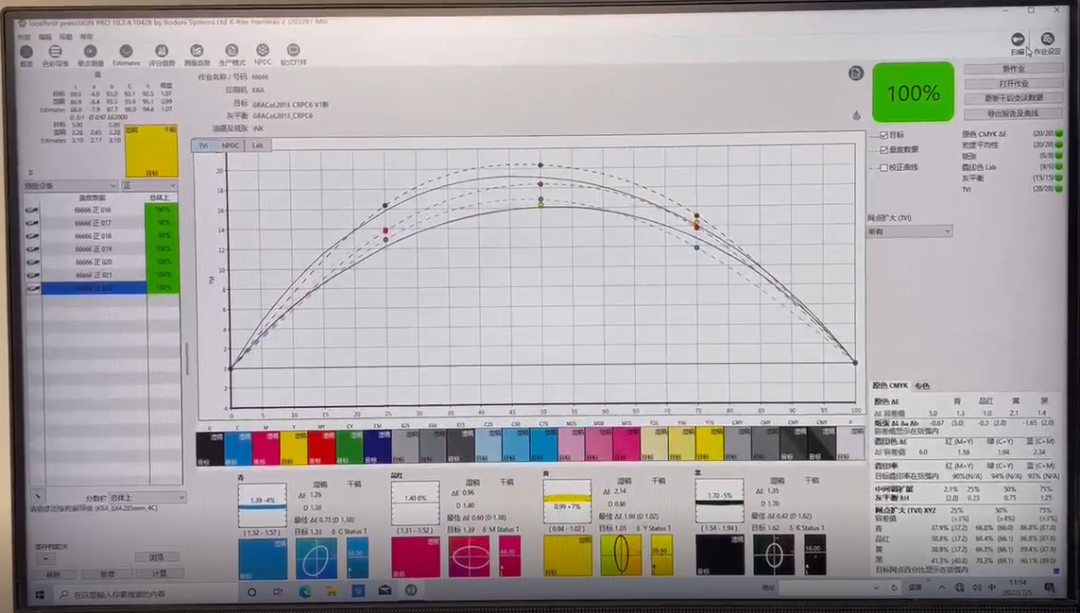

G7/GMI/PSO certification scoring: can be connected with scoring software as G7/GMI printing certification automatic measurement scoring system Press Sign

Expand your workflow - Press Sign scoring system

IntelliTrax2 introduced a new generation of color measuring instruments into the quality control process of the printing shop, and maintained highly consistent measurement results with the most widely used Ashley eXact handheld measuring instrument. Both commercial printing enterprises and packaging printers can ensure accurate color quality, quickly complete preparations and reduce waste. Seamless connection with the mainstream scoring system PressSign for G7/GMI certification measurement and scoring.

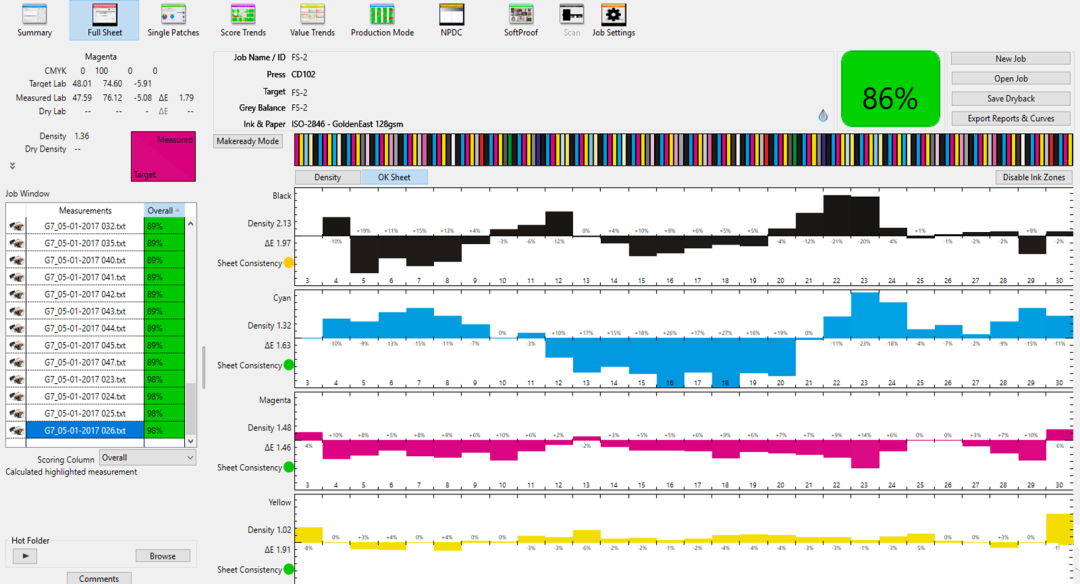

PressSIGN scoring system is a set of measurement, control, monitoring and evaluation system widely used in GMI certification and G7 certification for offset printing, flexographic printing, gravure printing and digital printing quality. Provide a set of analysis tools with rich functions to improve the working efficiency of the printing machine and operators, improve the printing quality and reduce waste.

PressSIGN Features

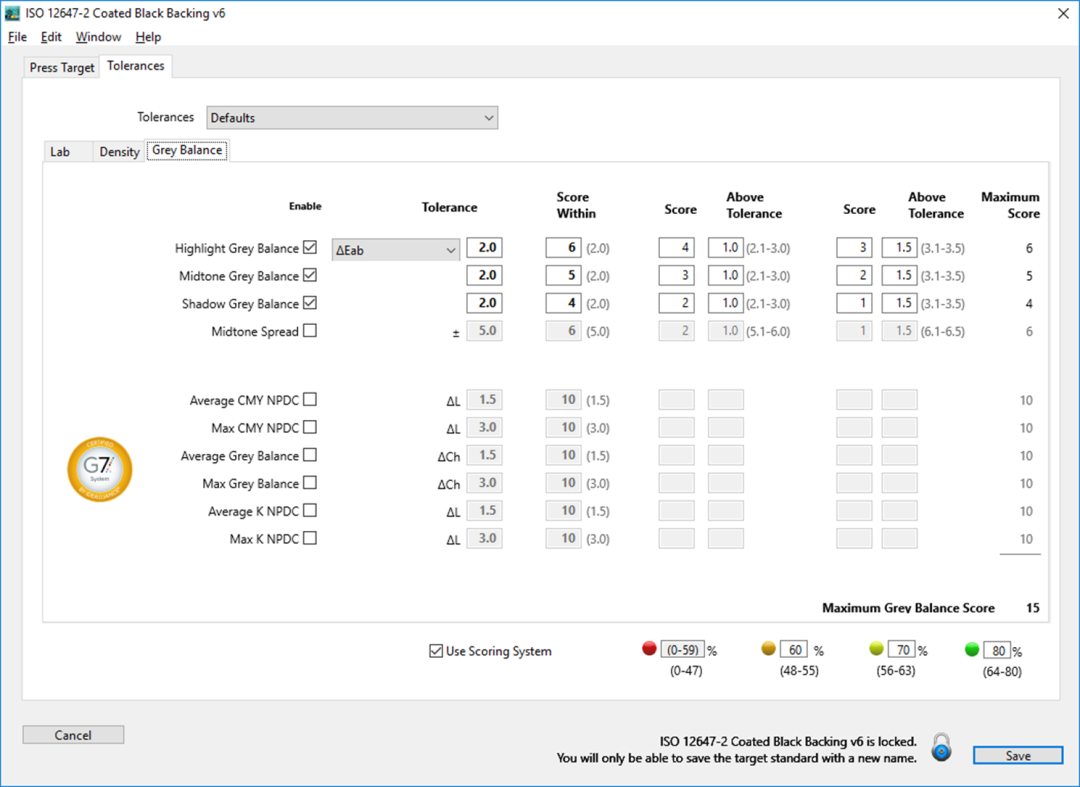

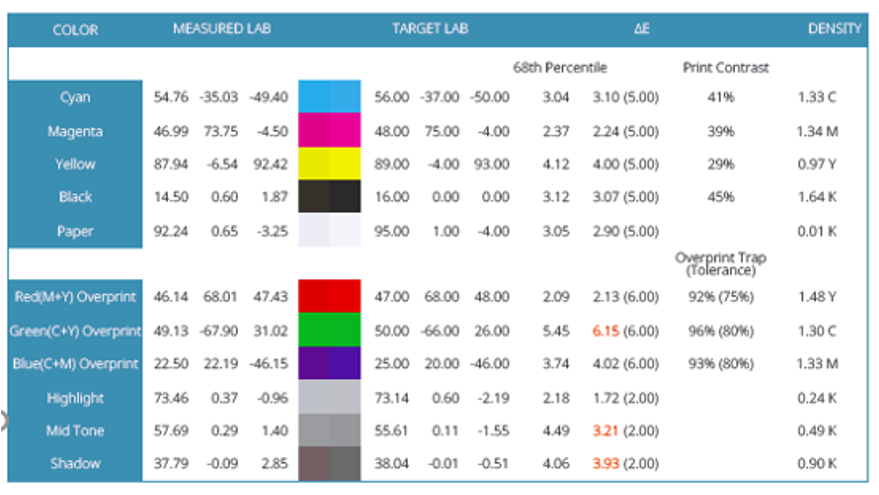

Scoring function: users can customize the standard and scoring method to measure and score the printing quality.

Dynamic density adjustment function: according to the predicted field density of the selected paper and ink, the ink key adjustment value is given.

Paper calculation: automatically adjust the target value according to the substrate to obtain the appropriate printing quality.

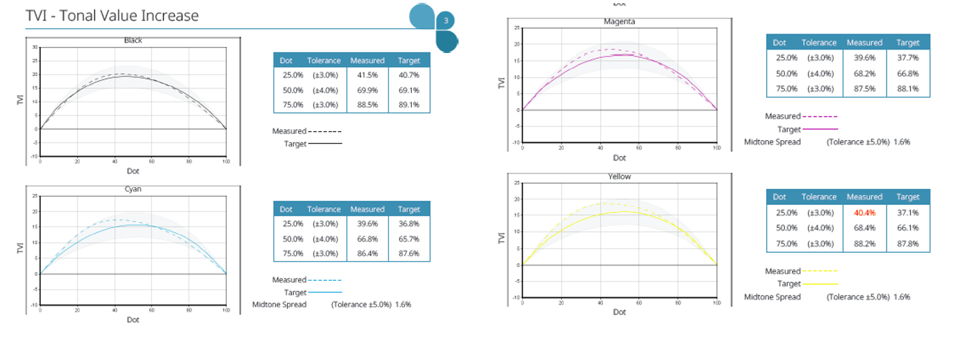

Dot compensation technology: generating curve compensation TVI (dot expansion), 4CX technology (grey balance) or neutral grey density (NPDC), pressSIGN has become a GMI certification and G7 certification system.

Printing standards: support multiple international printing standards, and users can customize (CMYK or iCC files).

Spot color support: built-in PANTONE color library, support up to 16 color printing control, support spot color dot control.

Based on WEB end report: report can be generated online (production, multi place printing comparison, operator, equipment, spot color, etc.), and trend performance level can be viewed through WEB interface.

Measurement and control strip: multiple measurement and control strips can be customized and exported.

Trend analysis report: printing press, operator, transfer performance, printing process waste.

Automatic mode: After entering the automatic mode, PressSign can automatically create jobs and send data to the server without the operator.

Supporting equipment: connect a variety of scanning spectrometer track scanning instruments eXact Auto Scan, IntelliTrax2, and a variety of single point, hand-held scanning measuring instruments exact, i1.

Case sharing - digital printing color quality control system

Now more and more printing enterprises have gradually introduced the digital printing color quality control system of "track scanning+printing scoring". This system makes the evaluation of printing quality objective due to the digitalization. It improves the printing quality as a whole, unifies the receiving standard, reduces the purchase cost, and also solves many disputes between buyers and sellers.

The printing automation integration scheme of Kaiyin Technology makes use of its enhanced optimal matching function to help manufacturers and brands provide ink density suggestions to operators according to the color difference between the spectral information of the target color and the measured spectral information, so that the printer head can quickly adjust on the printing machine to achieve satisfactory color matching. Less computer preparation time, saving ink, paper and labor waste, which can improve the daily workload and help enterprises obtain more income.

IntelliTrax2 is designed for ultra fast color control in the printing shop! It can scan the color band of a typical printing paper within 10 seconds, including measuring display density and color measurement functions, such as density, dot gain, printing contrast, gray balance, overprint, tone deviation/gray scale, chromaticity color difference, etc. It successfully interprets the status of the entire printing machine into data and displays it, and gives suggestions for inking.

Color management Color measurement can reduce preparation time and waste, and reduce errors and rework to a greater extent, which is the key to profitability. It is not possible to manage colors by eyes and/or by ink density measurement.

digital

the

and

printing

color

can

to

of

measurement

scanning

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time