Color management - spot color ink color matching technology

Product Details

In the new form, color quality and consistency are the chips for printers and packaging processors to win the market. If there is a problem with the ink, the incoming materials are unqualified or the formula is not accurate enough, the printing will inevitably be affected. Spot color matching process is often complex and time-consuming, requiring special color mixing skills and a lot of luck.

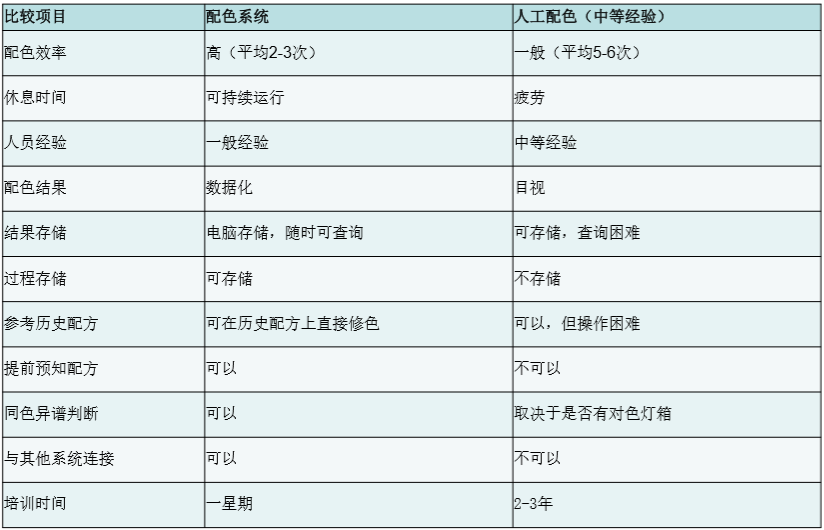

An important point to judge the quality of an ink system is the accuracy of color matching. The color matching system with high accuracy saves time and effort. The advantages of the Aiseli ink color matching system we recommend to you are reflected here. Most colors can reach the standard after the first correction, and the color similarity is high.

01 Current status of ink color matching

How do colors communicate accurately?

How to get the formula as quickly as possible when the customer specifies the spot color?

How to use the color database?

When changing ink and paper, how to match the original color?

Problems:

The deployment of spot color ink takes a long time, the calculation of spot color ink consumption is inaccurate, and spot color deployment lacks data management

The spot color inventory is overstocked, the ink is wasted seriously, the formula is incorrect, repeated deployment, and more out of tune

The two color samples differ greatly in visual inspection under different light sources, and spot color blending relies excessively on experienced ink blenders

Applicable to offset printing, flexographic printing and gravure printing:

The imported original color matching software and color detection instrument are used to greatly improve the color matching accuracy of the system;

Fast color matching to improve production efficiency;

It is easy to store the customer color scheme, and it is convenient to achieve stable chroma of different batches of ink.

With the ink color matching system provided by Kaiyin Technology, you can:

You can get the ink database free of charge and put it into production in the shortest time;

Both parties will also fully share the ink database, thereby greatly improving production efficiency and saving costs;

Many successful cases, including printing and packaging enterprises, ink factories and decoration companies, trained a group of professionals engaged in computer color matching in various industries. The computer color matching system is used to provide spot color ink for customers.

02InkFormula ink color matching software

Inkformulation is a computer ink color matching software of Ashley XRITE, which can provide fast, accurate and stable ink color matching, formula creation, storage, verification and waste ink utilization functions, and can be used in offset printing, gravure printing, flexographic printing and other processes.

Professional color matching for printers, packaging converters and ink manufacturers

Azeri InkFormula software provides a fast, accurate and consistent solution for ink color matching, formulation creation, storage, verification and retrieval for lithographic, flexographic, intaglio and screen printing inks.

The market expects that the printing color consistency is independent of the ink and printing conditions, while the ink with accurate color is very important to meet this requirement. Aseri's InkFormula software provides a solution that ensures the highest quality ink color matching.

This is not only used for new color matching, but also for the reuse of excess ink. InkFormulation6 provides ink suppliers and printers with more flexibility in formulation and ink series, improves the handling of basic materials, simplifies the definition of appropriate ink layer thickness, and helps eliminate harmful waste.

Because the advanced mathematical engine can better predict the interaction between ink and substrate, InkFormulation6 can quickly calculate the best and most effective formula according to the printing process, ink, lighting, pigment pricing, number of components and materials used.

• Improved basic material modules

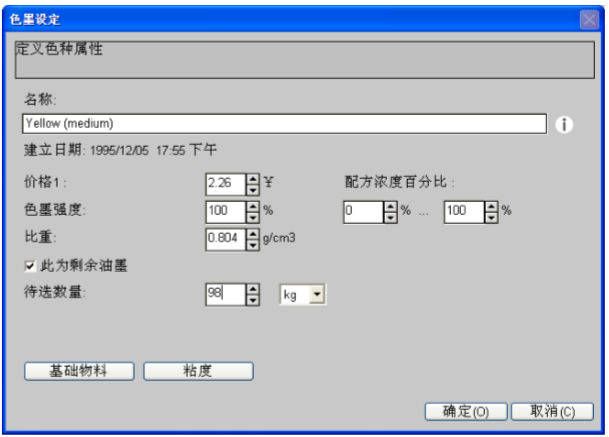

With the newly improved basic materials module of Version 6, users can use multiple additives in one ink series, so that a single additive can be changed in the formula without re sampling or creating a new ink series. This can significantly simplify the handling of ink series and formulas, and users can better control their ink databases.

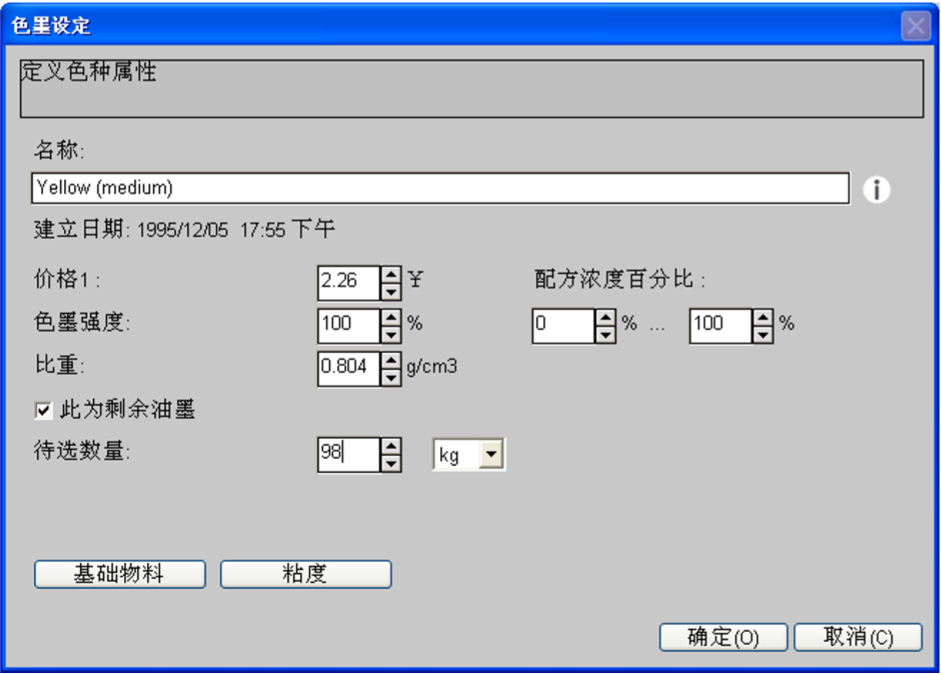

• Excess ink management

Necessary tools are provided to assist in obtaining colors. When used together with the famous oversupply management function of Aseri owned by InkFormulation6, the excess ink can be reused in the new formula in the color matching process. InkFormula has put forward a number of suggestions on how to reduce the amount of excess ink, which can be reused for new color matching, reduce inventory and waste, reduce processing costs, and provide users with a quick return on their InkFormula investment.

• Ink layer thickness calibration module

The ink layer thickness calibration module enables users to quickly and accurately determine the appropriate ink layer thickness for flexographic printing, gravure printing and screen printing. Users no longer need to re measure the known formula for different wire numbers or rollers, or manually adjust the ink layer thickness; They only need to input the roller or screen as parameters, and the software will automatically determine the required ink layer thickness. This allows faster preparation and reduces the number of ink series required, simplifying the color matching process. • Usage enhancements: InkFormulation6 has some usage enhancements, including: more flexible formula sorting criteria; Direct simplified access to the base material database; The new print layout editor allows users to define or customize their print layout (logos, barcodes and labels can be inserted and printed to mark ink cans and simplify inventory creation); The new "Undo" function allows users to return to the previous steps in the color matching workflow without having to start again; Simplified user management tools. • Data exchange: InkFormulation6 has achieved unmatched flexibility in data exchange by using the network database and Internet communication functions, so ink suppliers and printers can efficiently share color data anywhere in the world. Version 6 supports the new generation of CxF (Color Exchange Format), a common file format for color communication, so that they can accurately and clearly communicate all commercially important aspects of their ink color matching needs. At each step of the process, colors are defined and stored as CxF files, so in the entire printing workflow, instruments and applications can communicate seamlessly and faithfully. • Including digital color library: InkFormulation6 includes digital data coated paper and uncoated paper of PANTONEPLUS series color matching guide (including 336 new colors added in 2012 and 84 new colors added in 2014), PANTONEGoeGuide (coated paper and uncoated paper), PANTONE+Pastels (coated paper and uncoated paper), PANTONEMATCHING SYSTEM ® (C, U, M) color library and HKS (E, K, N, Z) color library. These color libraries provide M0, M1, M2 and M3 data.

02 Software Features and Advantages

Support ink color matching of various printing methods

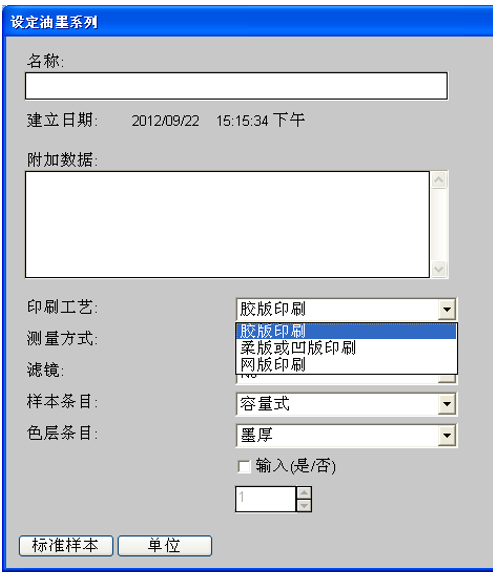

Azeri ink color matching system supports offset printing, flexographic printing, gravure printing, screen printing, etc

Support liquid ink viscosity correction

Input For liquid ink, when creating the database, you can enter the viscosity correction configuration file. When matching colors, you only need to select the viscosity of the ink you want, and the software calculates the amount of solution you need to add when matching the viscosity.

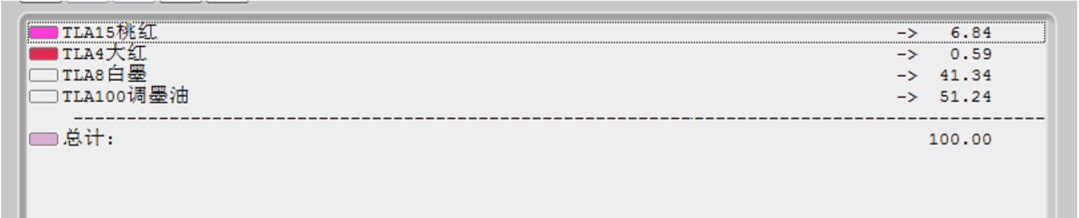

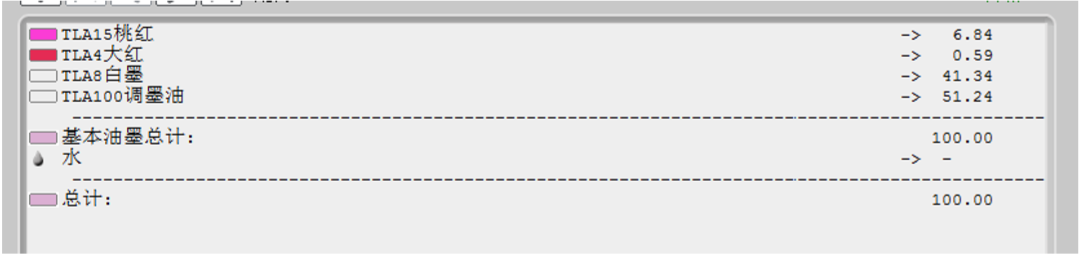

Display of ink formula

(ink to be printed)

(Basic ink and solvent)

(Basic Material)

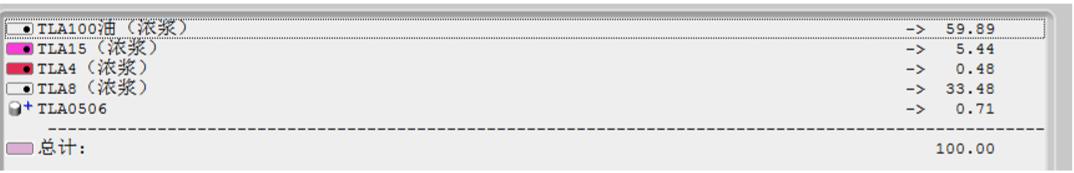

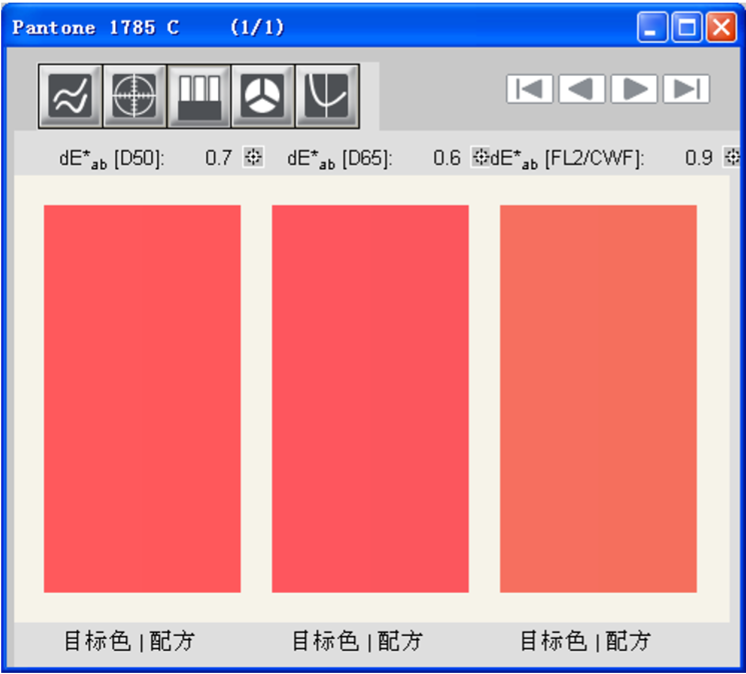

Multi aspect analysis of ink formula

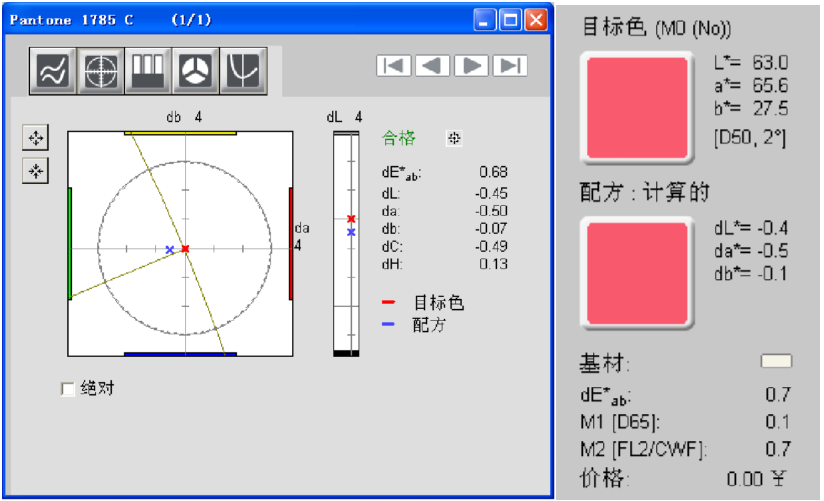

Data color, supplemented by color simulation. Display the data of the target color, the difference between the matched color and the target color, and the position and difference of the color in the CIE color space.

View the reflection spectrum of the color. If the spectrum coincidence degree of the matched color and the target color is high, the failure caused by the same color and different spectrum can be avoided.

View the visual effect of two colors under different light sources. If there is little difference under several light sources, the failure caused by metamerism can be avoided. On the contrary, it is easy to cause color mismatch due to different lighting conditions.

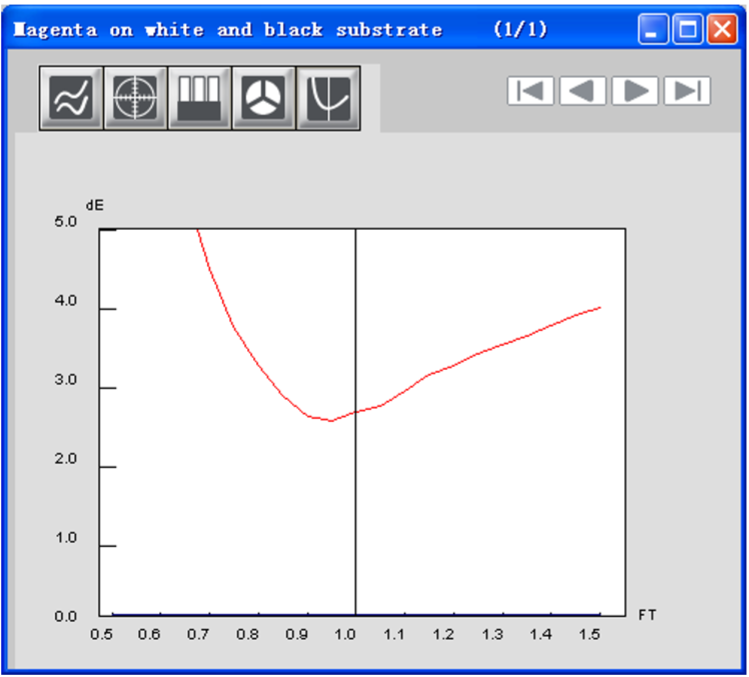

Check the color difference change when the thickness changes, and analyze whether the difference between the prepared color and the target color is caused by the different hue or thickness; And the minimum color difference that can be achieved by changing the thickness.

Utilization of waste ink

Reusing the remaining ink as a color can reduce inventory and waste.

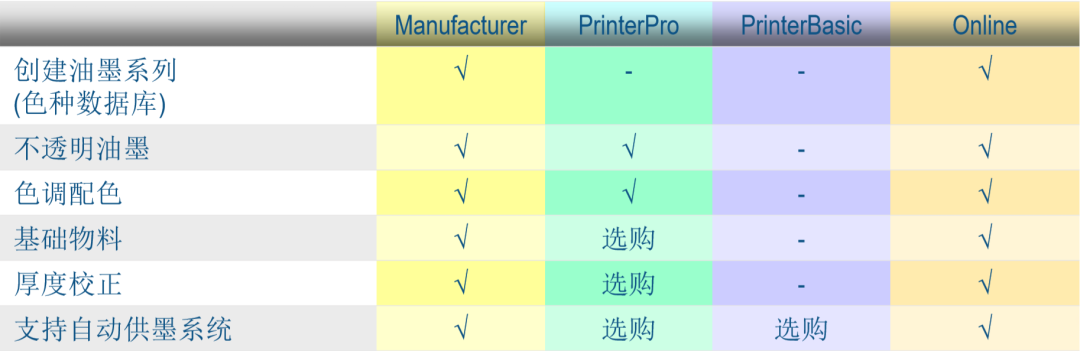

03InkFormulation6 is available in four versions

Buy the solution you need:

InkFormulation Manufacturer: A complete version of InkFormulation designed by the manufacturer for the ink Manufacturer, which provides the function of creating, storing and modifying the color paste database. This allows you to establish and maintain a complete color paste database that contains all the inks you use.

InkFormulation PrinterPro: It is not necessary to create or retain a color paste database when preparing custom inks. You can import and use the color paste database provided by your preferred ink manufacturer. ColorQuality software is included to ensure accurate measurement, continuous control and continuous archiving.

InkFormulation PrinterBasic: a cost-effective system designed for small and medium-sized printers. Using the database provided by your preferred ink supplier, you can easily and quickly dispense customized ink. This solution is the best choice for printers who have previously been unable to adjust the indoor color matching function correctly with the Aiselei color handheld device.

InkFormulation Online (online version): online solution for online customers of ink manufacturers and suppliers, enabling customers to use centralized and easily updated InkFormulation databases through the Internet. Printers who do not want to install the local ink color matching function can easily use the high-quality ink color matching database developed by many experts, and rely on the database to mix and match inks.

(Comparison of four schemes)

04 Auxiliary tools for ink color matching

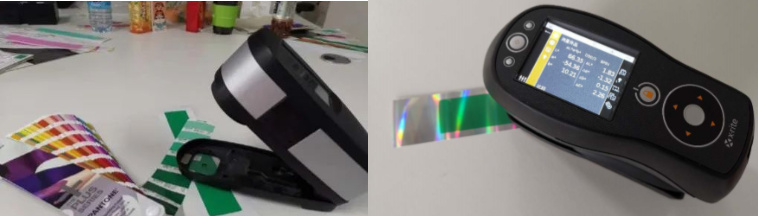

Colorimeter: use a small amount of ink to sample and simulate the color effect of printing;

Standard light source: use reasonable light source to visually judge the color;

Spectrophotometer: limitations of human eyes, data requirements, data entry, how to adjust metamerism and special materials;

Drying equipment: fast drying, improve color matching efficiency;

Electronic scale: weigh a small amount of ink for proofing → weigh the ink transferred to the substrate;

Viscosity cup (flexographic printing, gravure printing, silk screen printing, etc.): measure the viscosity of ink;

Small ink knife, glass sheet, quantitative instrument, etc.: assist in weighing ink and developing color;

ROI of ink color matching system

WeChat replies to Kaiyin Technology: "Return on investment in color matching system" or "ROI" to find the answer

color

the

and

ink

of

to

matching

can

printing

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time