Quansheng Q400/Q800 direct plate making machine

Product Details

01 Product Features and Advantages

Quansheng Q800/Q400 direct plate making machine meets the challenges of today's business environment and is greatly welcomed by the industry. Quansheng plate making machine is based on the direct plate making technology highly trusted by printers in the past 20 years, and has been developing constantly, helping printers to keep pace with the times in the ever-changing industrial environment. Now, Kodak Quansheng Q800 has added a number of new functions, such as more automation devices, faster speed, significant energy saving, etc., making the latest Quansheng direct plate making machine a wise investment for printing enterprises.

Market leading, reliable split or 4-way CTP equipment, excellent imaging quality

Automation, DITR film imaging, drilling and speed options to meet your business needs and budget

High quality and stable SQUAREspot imaging technology&new 4800/5080 dpi high-resolution option

Compared with the original design, the imaging technology saves up to 30% of the power, while only 770 watts

The new W-speed option creates the world's fastest flush free CTP

Open architecture: JDF/JMF open connection, PrintConsole 5, TDL and Windows 10 operating systems

Imaging of washless printing plate at the highest speed: 75 printing plates per hour for Q400 and 68 printing plates per hour for Q800

Q800 direct plate making machine

Output 2400 dpi/34 plates/hour (pph)

Printing plate size 1030x 838 mm

Standard and automatic unloading: F speed=22 pph, X speed=34 pph

Automatic updating/SCU/MCU: F speed=24 pph, X speed=41 pph, W speed=64 pph

Size of speed measuring plate: 838 x 1030 mm (drum circumference x drum axis)

Q400 direct plate making machine

Output 2400 dpi/34 plates/hour (pph)

Plate size 724 x 838 mm

Standard and automatic unloading: F speed=30 pph, X speed=43 pph

Automatic updating/SCU/MCU: F speed=33 pph, X speed=50 pph, W speed=75 pph

Size of speed measuring plate: 838 x 724 mm (drum circumference x drum axis) Repetition accuracy: ± 5 μ m, exposing the same plate twice in succession on the left side of the drum

Accuracy: ± 20 μ m, imaging two plates on the same device

Registration accuracy: ± 25 μ m, between image and text and plate edge

02 Product Functions and Environmental Benefits

Improve production capacity and promote business growth

The multi plate feeding unit can automatically load and unload up to 480 printing plates, realizing long time unmanned operation. The new W speed option allows users to image 75 4-open plates or 64 folio plates per hour, including Kodak Tengger non wash plates. If users are not ready to use the latest speed, they can also easily upgrade in the future.

Non impact printing plate - reduce the impact on the environment

Quansheng plate making machine is fully compatible with Tengri wash free printing plate, completely canceling the process of plate printing, and reducing the impact on the environment. In addition, Quansheng plate making machine is also equipped with a new cooling system, which significantly reduces energy consumption. When imaging, it is only 770 watts, saving up to 30% energy compared with the old model, and up to 90% energy compared with competitive CTP equipment. The plate making machine is compact in design and occupies a small area, which will also reduce the generation of transport waste, save costs and reduce the space requirements. In addition, the multi version unit is 65% smaller than similar multi version unit schemes.

State of the art imaging technology

Each Quansheng direct plate making machine is equipped with Kodak square spot imaging technology. Through this technology, no matter the sensitivity of the plate emulsion layer, the variables of the plate printer and the laser energy, it will ensure reliable and accurate imaging. As the printing plate reproduction and variable adjustment time are reduced, users will be able to reduce costs. With the help of Kodak digital printing plate, you will be able to output high-quality prints and become the only magic weapon to attract customers.

New applications for remote monitoring

The new and optional Kodak Mobile CTP control application allows users to monitor their Quansheng Q800/Q400 direct plate making machine through Android or IOS devices. Even if the user is not in the field, he can master the situation of the CTP equipment at the first time and restart the plate making quickly and efficiently.

Manual plate insertion

Cooperate with AL, SCU and MCU to provide; It can improve flexibility and normal operation time, allow the operator to terminate the automation device, and quickly re image a plate or a group of plates of different sizes from the plates in the master box.

Inline Hole-Punch

Cooperate with AU, AL, SCU and MCU to provide; Up to 10 punch heads can be selected for online punching, which will be used as a part of the imaging engine automation to provide the printing plate for quasi printing.

03 Multi model automation options

Advanced automation combines flexibility and productivity

Multiple models: 5 feasible automation options, reducing the error caused by plate making time and manual plate making.

New multi version box unit

Significantly improve production capacity and promote business growth:

It can automatically load and unload up to 480 printing plates, realizing long-time unmanned operation

Users can also load 4 different sizes of plates online to further improve efficiency and productivity

To meet the unique business needs of users, the system also provides other automation options

Semi automatic (SA) standard configuration:

Semi automatic loading and unloading.

Dimensions (H x W x D)/Weight: 160 x 200 x 120 cm/650 kg

Automatic version unloading (AU) Semi automatic:

Manual plate loading and automatic plate unloading to the plate printer or plate stacking machine; Automatic plate rotation device is optional.

Dimensions (H x W x D)/Weight: 170 x 200 x 128 cm/762 kg

Automatic Loading (AL) Automatic Loading and Unloading:

40 printing plates without backing paper (0.3 mm); Automatic plate rotation device is optional.

Dimensions (H x W x D)/Weight: Auto unloading: 170 x 200 x 128 cm/762 kg

Automatic loading: 184 x 200 x 128 cm/796 kg

Single version unit (SCU) is fully automatic:

It can load 120 plates of the same size and thickness with backing paper. Automatic plate rotation device is optional.

Dimensions (H x W x D)/Weight: 186 x 233 x 231 cm/1158 kg

Multi version unit (MCU) is fully automatic:

The four master boxes can hold 480 plates in total, and each master box can hold 120 plates of the same size and thickness with backing paper, realizing online imaging of plates of four different sizes.

Automatically select the corresponding master box according to the job definition.

Standard: 2 version boxes. Optional: 4 version boxes in total. Automatic plate rotation device is optional.

Dimensions (H x W x D)/Weight: 191 x 233 x 254 cm/1837 kg

Dimensions (H x W x D)/Weight: 191 x 233 x 254 cm/1837 kg

04 Kodak SQUAREspot square spot imaging technology

Accuracy, stability and reliability are superior

Kodak square spot imaging technology

Patented technology that has won international awards

Technology orientation:

1. The core of Kodak thermal CTP solution is resolution driver stability

2. Unique 10000dpi SQUAREspot thermal imaging and Sifangjia high fidelity FM screening, up to 10 micron dots

3. Excellent consistency

Unique advantages:

1. The highest resolution in the market today. 2. Compared with the old equipment, imaging can save a lot of power. 3. Automatic temperature compensation - accurate registration can be achieved even if the ambient temperature changes

4. Geometric correction - factory calibration, perfectly matching plates for different Kodak direct plate making machines

5. Dynamic auto focusing - reduce the possibility of hot spots and image defects

6. Built in laser backup system - effectively ensure the laser life and uninterrupted production operation

7. Automatic edge detection system - to ensure the accurate registration of the revision between the same equipment or different equipment

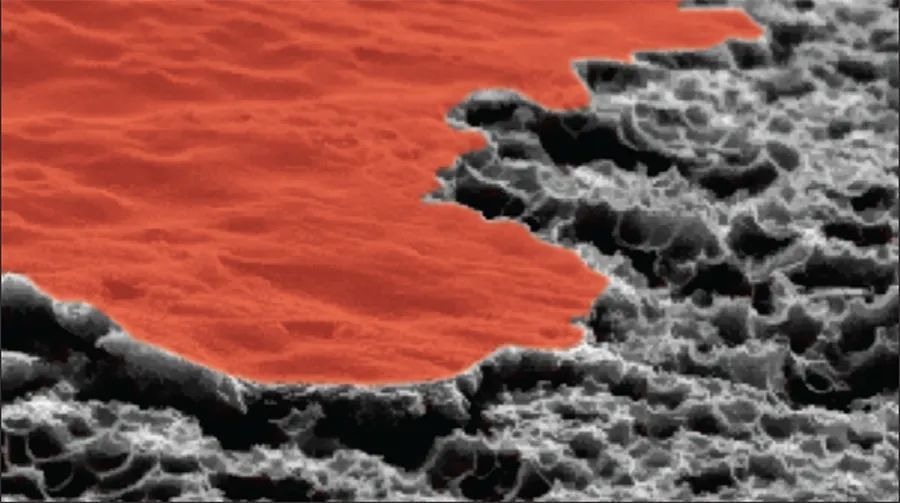

Traditional Gaussian dot (left figure)

For the printing plate output by non Kodak square laser technology, after being processed by the plate printer, the edge of the light spot is weaker than the center, which makes the dot easier to wear during printing, takes longer to preprint, makes the difference between the printed plate and the final print larger, and changes the color more during printing.

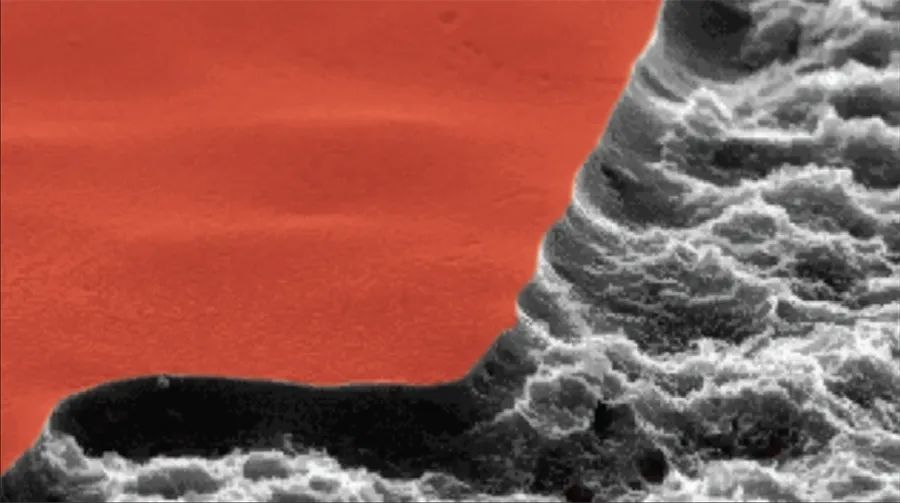

Square spot imaging technology (right figure)

The dot generated by the square light dot technology has a more solid edge, which makes it more effective than Gaussian or other dots to resist the wear on the printing press. Stable and durable dot can improve color consistency during printing, reduce pre printing time, and improve the printing plate's printing resistance.

The difference is obvious

The dot generated by the square light dot technology has a more solid edge, which makes it more effective than Gaussian or other dots to resist the wear on the printing press. Stable and durable dot can improve color consistency during printing, reduce pre printing time, and improve the printing plate's printing resistance.

Square spot imaging technology brings high stability

The square light spot thermal imaging head will ensure consistent tone on the printing plate, and can accurately image even under common changing conditions. In addition, it can also improve the service life of the liquid medicine. Combined with the intelligent "Dynamic Autofocus" function, the dot produced by the square light spot technology has unmatched accuracy, consistency and reliability, and has excellent performance on various printing plates.

What's the difference?

The 10000 dpi high resolution square spot technology can significantly reduce the Gaussian phenomenon and make halftone dots immune to common processing changes before printing.

Gaussian laser energy shape

GLV laser energy shape

Square spot energy shape

Perfect combination: square light spot technology and Kodak Tengger non wash printing plate

Improve laser efficiency: to obtain similar printing performance, the required energy is reduced by 27%

Fast color reproduction: it is transferred from a developed printing plate, and dot gain calibration is not required

Excellent color stability: the highest screening performance can be obtained by using the same type of wash free printing plate

making

the

and

plate

printing

of

to

is

automatic

plates

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time