Tengger XTRA wash free printing plate

Product Details

Background of wash free plate

If you can make your production faster, if you can make the quality of the printing plate higher, if you can reduce the cost. Imagine, which enterprise would reject these? In the past two years, there have been more and more plates that are not washed or chemically treated on the market. As market competition is always fierce, printing enterprises will naturally put forward higher requirements for productivity and profitability. No washing/no chemical treatment board can help them improve production efficiency, reduce the cost of plate making, and improve the brush quality; So as to help printing enterprises save money and simplify the prepress process of printing plate.

Kodak Tengger non wash plate is a global plate. The newly developed and produced Tengger plate of Kodak cancels chemical washing, eliminates all the changing factors in washing, realizes stronger process control, and improves the reliability and stability of plate making. Like Kodak's previously famous thermal printing plate, it represents the high quality, resolution, accuracy, reliability and repeatability of printed matter.

Simplify process and improve efficiency

Kodak Tengri Sonora non wash plate

Kodak Tengri non wash version has the world's good quality, productivity and printing performance, which will not only meet the needs of commercial sheet fed printing, but also bring strong printing performance for commercial thermosetting and cold setting rotary printing machines, offset printing packaging applications, and even short version UV printing. With these strengths, Tengger printing plate can be applied on a large scale. Tengger printing plate can output 1~99% @ 200lpi, 20 μ Up to 200000 prints can be obtained through FM screen, and 100000 prints can be obtained through ordinary sheet fed offset printing.

Many people have formed a preconceived concept when they mention the CTP free plate, that is, although the CTP free plate is environmentally friendly, its price is high. However, if we can have a more comprehensive and in-depth understanding of the huge cost savings and profit improvement brought about by Sonora Tengger non wash printing plate, the previous concerns will be solved.

At present, CTP plates on the market are mainly divided into three categories

Traditional CTP plate, chemical free CTP plate, treatment free CTP plate

The plate making process is as follows:

Traditional CTP plate → plate making machine exposure → developing, washing, gluing, drying → machine printing

Chemical treatment free CTP plate → exposure of plate making machine → development and gluing of punching machine (at the same time), drying → machine printing

CTP plate without treatment → plate making machine exposure → printing on the machine (water saving, zero chemical treatment)

Kodak no longer uses washing machine and chemical solution for flushing -- no flushing

Do not use flushing chemicals, waste generation and flushing equipment

Reduce water consumption, energy consumption and cleaner working environment

The following operations are no longer required after using the Tengger wash free version

Clean the washing part, replace the filter element and clean the developing tank

Simplify process and improve efficiency

No need for washing machine: cleaning, maintenance, service, accessories, spare machine to strengthen processing control

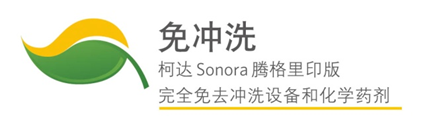

Plate making cost: plate printing, chemical solution, energy, water, waste and labor - 50%~- 75%

Press downtime (lost revenue) - 5%

lower production cost

10000 square meters=180000L of water; 800KW/h, flushing cost reduced by - 35%/total section - 25%

20,000 square meters=360,000 water; 1600KW/h, flushing cost reduced by - 25%/total section - 10%

Reduce the cost of sewage treatment (waste liquid medicine after use)

First of all, let's have a deep understanding of the imaging technology used in this plate, that is, the unique Kodak quasi printing technology. Its basic principle is to absorb the fountain solution at the start-up stage of the printing machine and physically remove the non imaging coating under the effect of the ink shear stress. This will ensure the smooth transfer of the coating from the printing plate to the blanket, and then it will be taken out of the printing machine by the coated paper. In most cases, it can be completed after the first few preprints or newspapers.

Comparison between Kodak's no rinse version and no treatment version

Comparison with treatment free

1) Tengger fast color tracking, less sheets required for cleaning the printing plate

2) Tengger printing plate does not need special fountain solution

3) Wider range of printing applications, including short version UV printing

4) More stable printing performance

5) Better image contrast

6) Widen the range of safety light requirements

7) Tengger VLF large format

Comparison with glue treatment

1) Faster imaging and higher productivity;

2) Better control of the process by eliminating all changes in flushing

3) No burden of maintenance, cleaning equipment and replacement of liquid medicine

4) Eliminate flushing chemicals, energy, water, waste and time, and reduce operating costs

5) Eliminate the energy required for flushing and the disposal of waste glue, and reduce the impact on the environment

6) Tengger VLF large format

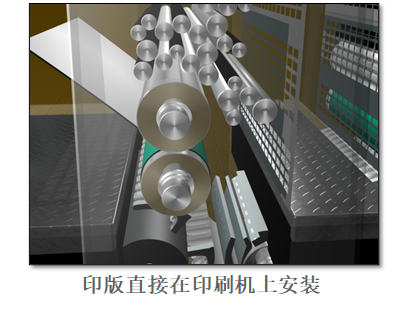

The Technology of Kodak Free Development Plate on Printing Press

Installation of printing plate on printing machine

Install as any other printing plate;

It can work with manual and automatic version updating systems;

The image has strong contrast and can read 10pt The font size of the roller is convenient to distinguish.

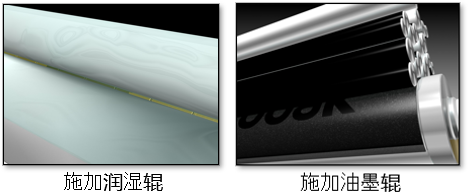

Press start

Apply a wetting roller and an ink roller, and coat the whole printing plate with fountain solution and ink;

Moisturizing solution allows physical removal of coatings in non graphic areas;

The shearing force and viscosity of the ink transfer the un imaged coating to the blanket.

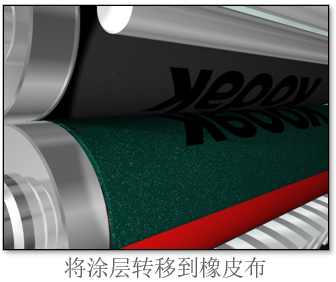

Transfer the non imaging coating from the printing plate to the blanket through pure physical action;

This is a physical action rather than a chemical reaction, which will meet the requirements of a wide range of printing press chemicals and printing press setting conditions, and eliminate the change factors related to traditional wet flushing systems.

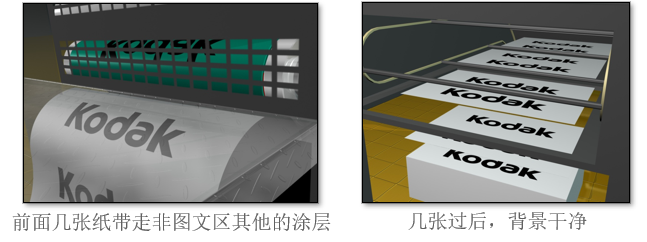

Input the master pass paper, and the coating is transferred from the ink on the blanket to the first several sheets of master pass paper and taken away;

It will not pollute the ink and wetting system;

Usually the background will be clean after 5-10 pictures;

Registration and color adjustment are the same as any other printing plate.

Kodak Tengri series non wash printing plate is a mature and environmentally friendly printing plate in the industry, which meets the environmental requirements. Enterprises using it can achieve environmental protection and compliance, and get real water free, chemical free, flush free machine, power saving, labor saving, good dot and high print resistance. It can also do many benefits of UV printing, helping enterprises create new value. This is also the most successful part of Kodak's quasi printing technology. The advantage of Sonora Tengger's non wash printing plate is its economic and environmental advantages.

Practice environmental protection - Kodak wash free version

Trend of macro environmental factors

Water shortage: pollution, flood and drought, water ecology, and management

Power consumption in China increased in 2014

In 2015, China's economy grew by 7%, and consumer goods and packaging increased

More strict environmental protection and government supervision

Reduced labor force in the printing industry

Common points of printing enterprises

Prepress costs - chemical, energy, water and waste

Washing machine - cleaning, maintenance, service, accessories, standby machine

Strengthen processing control - affect printing quality, re plate making and re printing

Environmental compliance - new laws or regulations

Environmental protection pioneer vs pollution enterprise

Tengger wash free printing plate

EUROPE Europe: Growth>200%

US&C Americas: growth>400%

ANZ Australia: Growth>50%

LATIN AMERICA Latin America: Growth>100%

ASIA Asia: growth>200%,>70 users,>300 developing users

The production plant is located in Xiamen, which is fully promoted in China and won the 1st Green Industry Award

Statistics of 2000 successful cases

Water saving: 256348691 liters=128175 liters on average

Energy saving: 99023328KWh=50000KWh

(Running: ~5.1 KWH,Standby:~0.5 KWH)

Chemicals reduced: 1742653 liters=870 liters on average

tengger

the

and

printing

plate

of

is

machine

free

can

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time