Imaging Engine

Product Details

Fast sharp: quality and performance

Based on the Adobe PDF printing engine kernel, Fast Edge is a high-quality, high-performance RIP solution.

It integrates screening and calibration technology suitable for flexographic printing, allowing you to optimize the use of CDI plate making. Output to file via image engine and verify with tools to reduce loss and error rate.

In addition to being the perfect RIP solution for CDI, the image engine can also create files in other open image formats, such as TIFF. Therefore, it is also applicable to the production of other printing processes, such as offset printing, relief printing and intaglio printing.

Based on Adobe PDF printing engine kernel

Adobe PDF printing engine provides an industry standard based on pdf, so you can be confident in the output results, even for complex files with transparent blending effects. It has a 4-bit multiprocessing software architecture that optimizes the use of computer platforms to provide the performance you need for production.

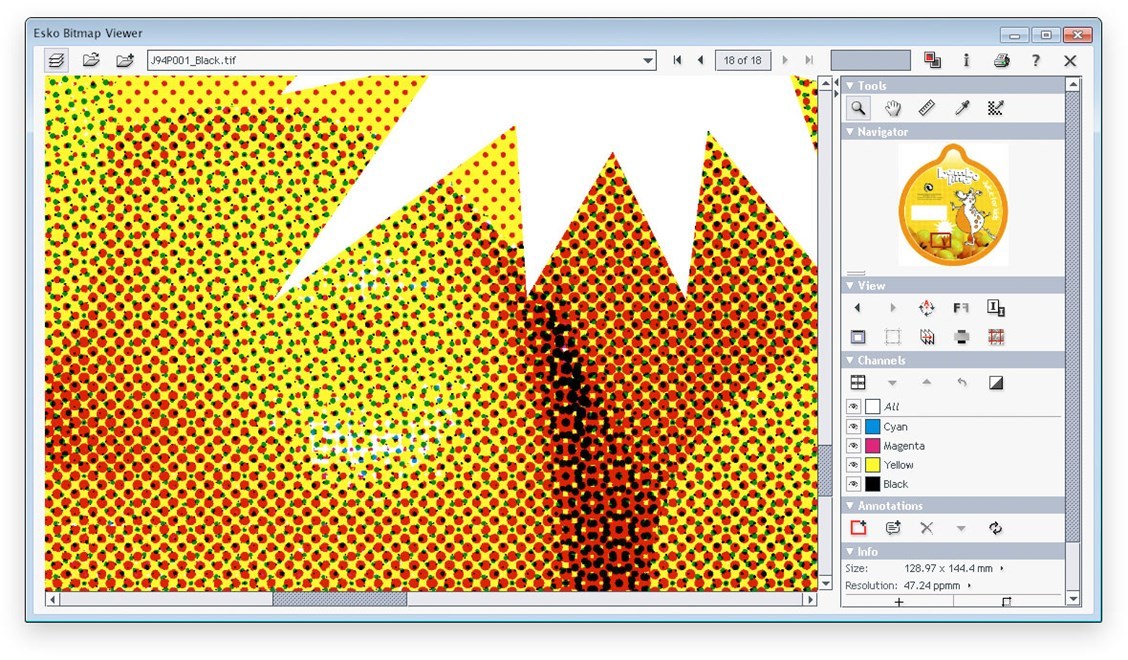

Esko Bitmap Viewer: a powerful quality control tool

Bitmap viewer is a powerful quality control tool, which can repeatedly verify the data content before output to ensure printability.

Users can set preview rules, angles, trapping, line width, dot gain, resolution, seamless inspection, minimum point size and more key data for work.

In addition, the Esko Bitmap Viewer compares different versions of the job and automatically highlights any differences. The Esko Bitmap Viewer clearly shows any errors before platemaking, saving time and significantly reducing waste.

Screening

Whether using offset printing for brochures, flexographic printing for food bags or other printing applications, screening is a key factor in printing quality.

Esko has a wide range of halftone screening technologies, and each screening method is optimized for a specific printing process.

engine

printing

the

and

for

to

in

is

screening

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time