Equinox Colorful

Product Details

Accurately print the brand color with fixed color holder ink

With the change of product diversity and the increasing demand for shortening the packaging production time, packaging printers need a time - and cost - effective way to meet these challenges.

By converting spot colors to fixed print color holders, downtime between jobs can be reduced and productivity can be improved. There are two ways:

Convert spot color to CMYK remove spot color

Use extended color gamut (CMYK+2 or 3 additional inks) to remove spot colors

Benefits of using extended gamut printing

Reduce the stock of spot color ink

Less cleaning time during printing

Improve productivity and reduce downtime between jobs

It can be printed in a mixed way

Use new printing technology to achieve brand color matching

Our goal is to reduce the printing downtime caused by color changes. By using the same ink color holder after converting all printing jobs, extended gamut printing eliminates the need for cleaning when switching jobs, and reduces the time for printing preparation.

Reduce printing cost by expanding color gamut printing

No ink change means more normal production time

Thinner ink thickness can improve printing speed

There is no color limit. You can combine files to achieve mixed printing

You know what?

Whether you are printing in cartons or narrow labels, the use of extended color gamut printing technology can save a lot of money by increasing uptime. If you don't believe me, please look at the figures below.

Choose your color gamut space

Overcolor allows you to choose different ways of converting spot color to CMYK or expanding color gamut printing

Generally speaking, according to the requirements of printers and brand owners, CMYK fixed ink color holders can replace some or all of the spot colors.

If you use Overcolor, you can easily use the printing color CMYK and additional ink to expand the printing color gamut space and better meet the color needs of brand owners. Overcolor provides completely visible color gamut space and predictable color accuracy judgment, allowing you to make better choices before printing.

Extended gamut printing

Extended gamut printing allows you to print faster and achieve superior print quality while reducing your printing costs.

Overcolor is Esko's solution for expanding color gamut printing. It can use a set of fixed inks of your choice on the printing press, and at the same time cooperate with the standardized operation of the entire printing process. In this way, you can save a lot of time for packaging production to save consumables (ink and paper) at the same time, because the order transfer between the original printing production orders and ink change and printing preparation only need to change the printing plate.

Want to know more about extended gamut printing?

What is Extended gamut printing?

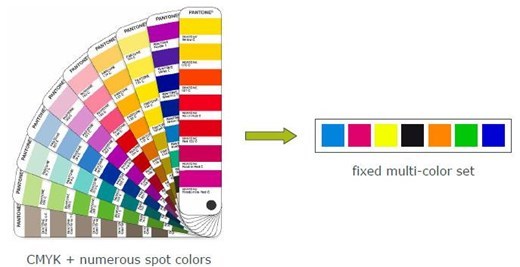

Extended gamut printing means that the packaging is not produced in the combination of the original CMYK and spot color ink. Extended gamut printing usually uses CMYK+2 or 3 additional inks (such as orange/green/blue purple). By adding additional colors to the traditional CMYK to increase the printing gamut space, the printing machine can simulate more and more accurate colors.

The use of color printing process printing presses does not need to replace spot color ink for each packaging production order, so they can improve productivity and reduce the cost of ink. At the same time, printing quality and color consistency have also been improved to meet the needs of brand owners. Brand owners themselves are also seeking to reduce costs without affecting accurate colors and high-quality printing methods.

What is Extended gamut printing?

Extended gamut printing means that the packaging is not produced in the combination of the original CMYK and spot color ink. Extended gamut printing usually uses CMYK+2 or 3 additional inks (such as orange/green/blue purple). By adding additional colors to the traditional CMYK to increase the printing gamut space, the printing machine can simulate more and more accurate colors.

The use of color printing process printing presses does not need to replace spot color ink for each packaging production order, so they can improve productivity and reduce the cost of ink. At the same time, printing quality and color consistency have also been improved to meet the needs of brand owners. Brand owners themselves are also seeking to reduce costs without affecting accurate colors and high-quality printing methods.

equinox

the

printing

color

to

and

gamut

of

can

extended

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time