Color Engine

Product Details

Excellent professional color management tools for packaging and labeling

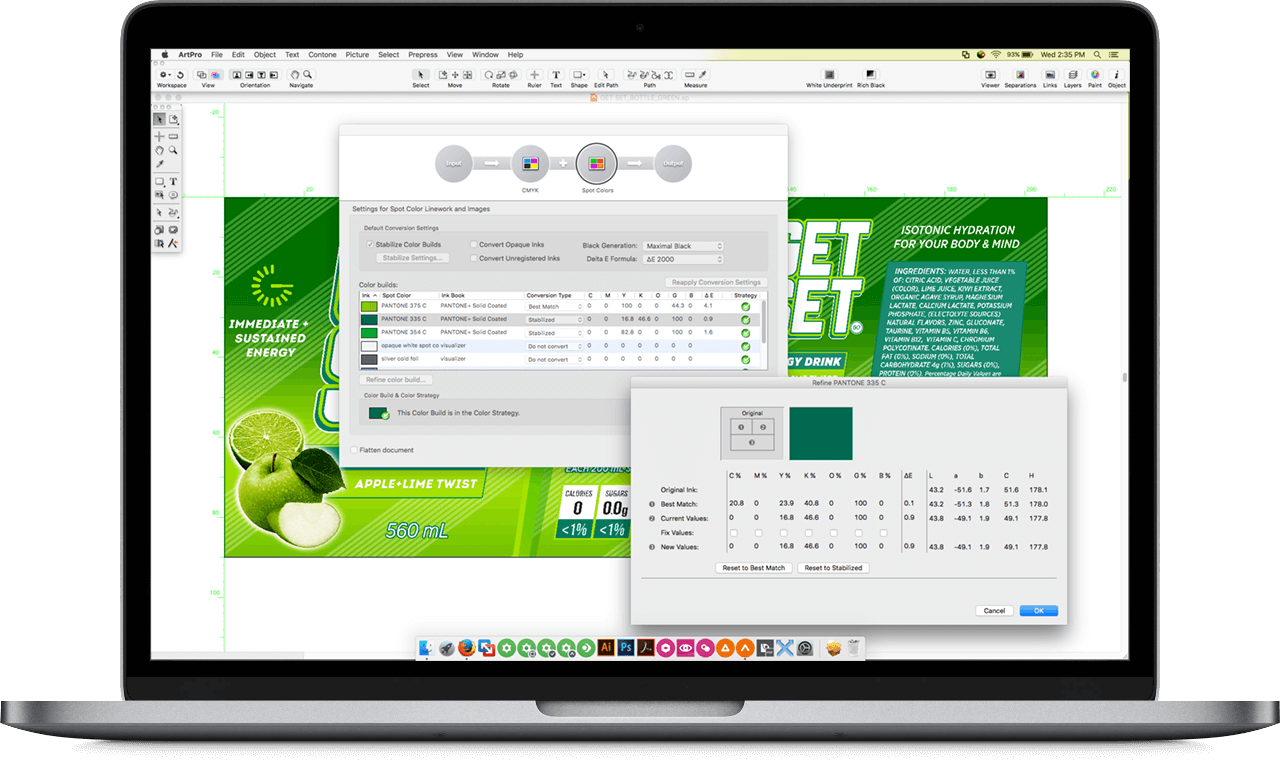

Through the application of color engine, color management can span the packaging and printing supply chain. Its core is a central color database with all color characteristic data.

Color consistency is the key to improving brand awareness. Defining accurate brand and spot color standards is the first step to maintain color consistency. The next step is to use these standards in all packaging design and production applications.

If you don't have a measurable color management process to help the printing factory keep on the right track, you can't print on the basis of meeting color consistency.

Color engine

The color engine allows you to successfully manage the brand's color expectations.

It consists of two parts:

As a color management tool, the color engine can accurately predict the performance of brand colors on the packaging of finished products before the brand owner signs for production.

The color engine is a way to convey color information to all relevant personnel in the packaging supply chain, because brand owners, designers, prepress operators, printing plants and ink plants in the entire packaging supply chain need to use the same color data.

digital proof

Esko Caiyi provides accurate color contract proofing through the selected inkjet printer

Brand packaging widely uses designer (spot color) colors, and also uses a variety of printing processes, including digital printing, offset printing, gravure printing and flexographic printing.

By using Esko digital proofing at the beginning of production, the expected color can be accurately simulated and the printing production can be optimized, thus avoiding errors and waste.

Extended gamut printing

With the change of product diversity and the increasing demand for shortening the packaging production time, packaging printers need a time - and cost - effective way to meet these challenges. Extended gamut printing is one of the ways to achieve this requirement.

Extended gamut printing allows you to print faster and achieve superior print quality while reducing your printing costs.

Overcolor is Esko's solution for extended gamut printing.

Overcolor uses fixed 5/6/7 printing color holders (extended color gamut), which can enable your printing machine to achieve standardized management. In this way, you can save a lot of time while saving consumables (ink and paper) for packaging production, because the order transfer between the original printing production orders and ink change and printing preparation only need to change the printing plate.

Color management that can be used in the whole supply chain by Yunpan Tong

The way of Cloud Pantone can make the brand color digital. In a safe and centralized cloud ecosystem, brand owners, designers, production personnel and anyone in the supply chain can use it.

color

the

printing

and

to

of

packaging

can

brand

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time