Package software 12 Printing production and management software

Product Details

Package 12 is an integrated software solution for packaging, labeling, display shelves and commercial printing.

The software package 12 has good scalability, is easy to use and learn, and provides a complete and comprehensive solution for design, prepress and production. Software package 12 can be integrated with other business systems to achieve the best results through a complete terminal to terminal approach.

Package 12 has the following functions:

Structural software for packaging design and production

● 3D design, including store simulation

● Automatic draft creation

● Pre press editing of packaging

● Continuous drying, plate assembly and folding

● Workflow automation

● Color management

● RIP, screening and output control

● Packaging approval and document management

● Packaging project management

● Asset management

Software package 12: create added value, improve efficiency and reduce costs

Software package 12 design, prepress, process and management tools cover a wide range of professional software applications, and are suitable for packaging, label and display stand production industries.

Packaging buyers focus not only on individual labels or packaging boxes, but also on all the content on the product packaging that conveys brand information. Moreover, since packaging is the most important carrier of brand information, packaging buyers need tools to manage the process.

Software Package12supports this integrated solution with tools that create added value, improve efficiency, and reduce process costs. Esko users can enhance their ability to influence, dominate and control the packaging supply chain through the software package 12.

Esko users will find that their investment has been well rewarded. Package software 12 adds powerful new functions for prepress editing, 3D visualization, quality assurance, color management and process automation, without the need to redesign the operation process or retrain operators.

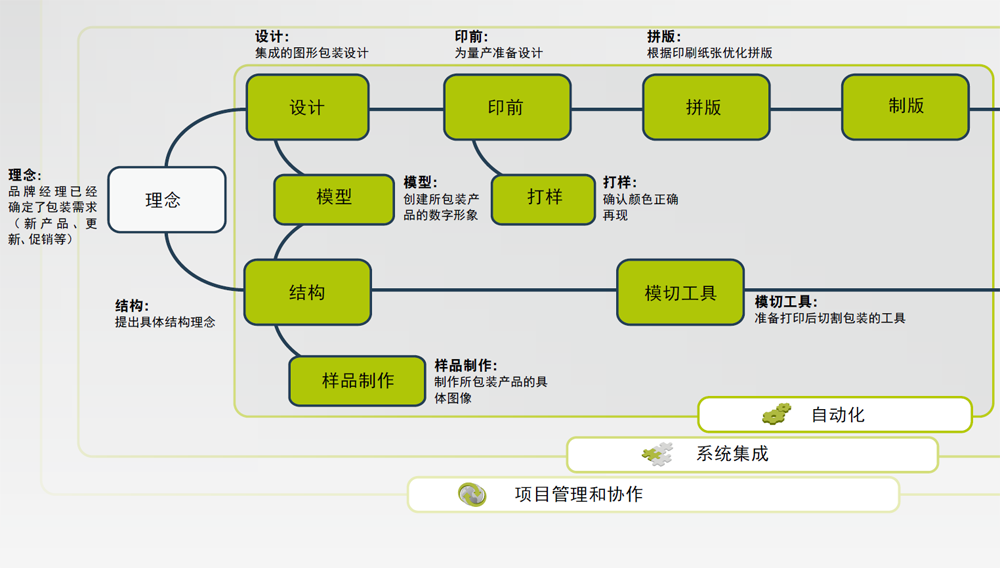

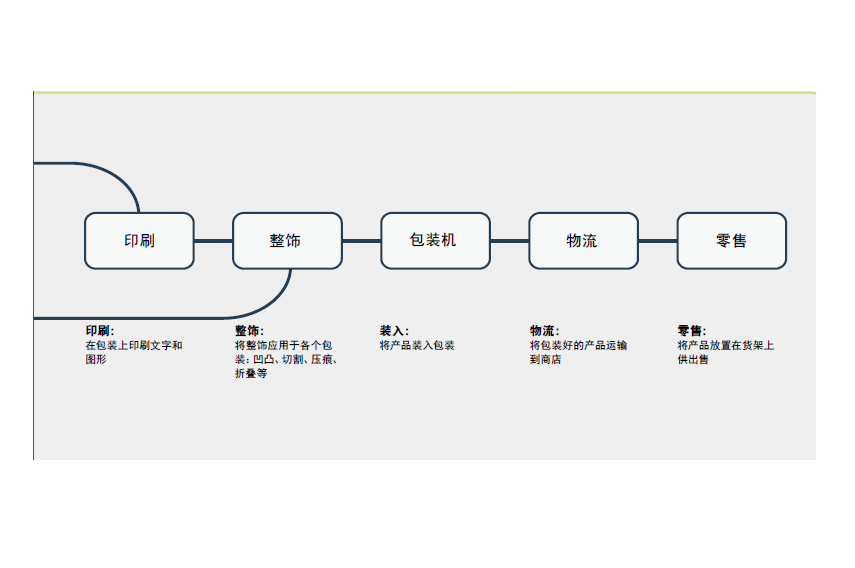

Packaging production process steps

For brand owners, packaging refers not only to a single label or carton design, but also to the overall embodiment of the brand, including all elements of the entire brand experience.

Design packaging and display shelves

Design packaging in 3D mode

Packaging and display shelf development started with structural design.

Whether it is to make folding cartons, corrugated cartons, directly shelvable packages, packaging bags or protective cases, ASK can provide you with the world's leading structural design and production tools.

These tools can improve creativity and productivity in a demanding production environment.

Global standards for structural packaging design

Artoo includes special tools designed for packaging professionals. For them, Artoo is a powerful toolbox for structural design, product development, visual proofing and production. Artoo can improve the productivity of the whole company. Artoo is the ideal choice for designers of all corrugated boxes, folding cartons and POP display shelves.

In Adobe ® Illustrator ® Medium and rapid packaging design

Packaging is not flat, why work in a flat world? Studio is an easy-to-use tool for 3D packaging design.

Studio is very fast and easy to use, because it is integrated with Adobe, the tool you have already used ® Illustrator ® Medium.

The studio will help you make more excellent drawings. Whether you are a designer trying different ideas, or a prepress operator checking the matching front and back, the studio can let you freely control the process related to packaging.

ArtiosCAD

Artoo provides design and drawing tools for the structural design of cardboard packaging and display shelves. Comprehensive 3D interaction can realize rapid production of samples of design and display articles, avoid communication errors and shorten the design review cycle. Artoo can create layout and die cutting, and

Optimize the production equipment used in production.

Yatu Enterprise

Store all production documents, design drawings and material inventory to a private cloud platform. Through easy and secure access from the Internet, Artoo Enterprise connects all internal and external stakeholders with a unique set of production documents. This means that there is no need to copy data, search for specific designs, or waste material.

Studio

Studio is a group of tools to add 3D patterns and overall solutions to packaging design.

Studio Designer

Studio Designer explains the overall vision of Eskom for pre press packaging production: it not only displays the various elements of packaging projects, but also previews each component individually or "as a whole" in 3D, so as to achieve faster, more effective and more accurate packaging design; And these are all in Adobe ® Illustrator ® In.

ESCO Store Visualiser places 3D packaging design on virtual shelves. See how the design works in an interactive, dynamic 3D retail environment.

Studio Toolkit

Studio Toolkit adds an easy-to-use structure design tool to Adobe Illustrator.

Studio Toolkit helps create basic folding carton and corrugated carton designs, containers (bottles, cans, jars, etc.) and labels, as well as all flexible packaging designs, including shrink protectors. These CAD structures can immediately present 3D virtual layout of graphics and structures.

Studio Visualizer

The studio special effects master can carry out the final retouching. Its patented dynamic printing visualization system can preview various substrates, printing and finishing effects in real time. Through special effects masters, you can share the results as pictures or movies.

Studio Store Visualizer

Studio Store Visualizer provides an extremely realistic visual experience, enabling your packaging design to be placed in a virtual dynamic retail environment.

Pre press editing of high-end packaging

Eliminate production errors

"This is wrong!" This may be the last thing you want to hear after you have produced a certain product. It not only wastes a lot of time, but also may waste huge amounts of money. However, there are ways to better control the risk of production errors. These tools can improve creativity and productivity in a demanding production environment.

Pre press function dedicated to packaging

Packaging prepress professionals don't like to take chances: they choose special prepress editors Apollo and Packaging Century, or use DeskPack (Adobe ® Illustrator ® Package prepress production series plug-in).

This function has been recognized and praised by industry professionals. All editors share the same rich packaging functions, such as barcode editor, color register software, 3D preview, linking and SmartMarks.

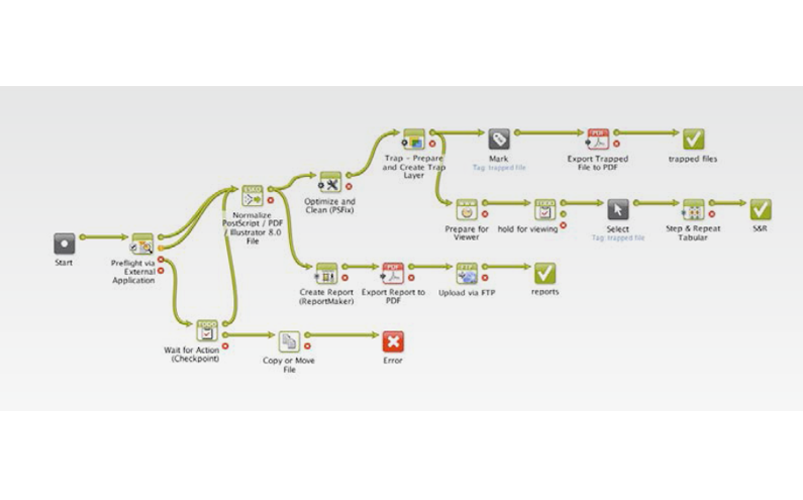

Streamline processes

It can further promote the automation and integration of prepress, so as to reduce the cost of prepress production of packaging and reduce the cycle time. Workflow is defined in a very intuitive and easy to use way. The automation engine is the core of the prepress process, which can organize projects and data assets and automate repetitive and daily tasks.

ArtPo and PackEdge

Apollo (MAC) and Packaging Century (PC) are editing software for label and packaging prepress production. They contain special tools that can deal with the main problems in prepress production (such as overprint, deformation, screening, barcode, continuous drying, etc.).

Apollo and Packaging Century have rich functions and can prepare for the mass production of packaging design, using various printing technologies (digital printing, lithographic printing, flexographic printing, intaglio printing, screen printing, etc.).

DeskPack

Package printing energy is used for Adobe ® Illustrator ® CS and Adobe ® Photoshop ® CS is a group of professional prepress plug-in tools.

Esko integrates the best packaging prepress technology into the world's most popular design tools.

When working in your favorite design software, package printing can significantly reduce errors, shorten delivery time and reduce costs. Package printing enables Adobe to ® Illustrator ® And Adobe ® Photoshop ® Become a full-featured pre press workstation for packaging.

Design studios, traders and printers all over the world rely on Esko's prepress tools to prepare for packaging and labeling.

Packaging approval and document management

Control the production process

In many companies, the first draft and revised documents of the design are sent back and forth via email in the product management, marketing, packaging development and prepress production departments until the final draft is confirmed. This is very error prone and time-consuming.

All assets are concentrated in one central point

It is important that all assets are concentrated at a central point to simplify the process in this regard. All data can be shared online at a dedicated central point.

All stakeholders, including product managers, packaging buyers, designers, traders and printers, can view the same elements online to achieve the highest level of collaboration.

Smooth workflow for increasing complexity

Smooth automated workflow is a powerful assistant, because it can avoid all inefficient work. All process steps are automated without any human intervention, which can free up expert resources and complete more value-added tasks. Fully integrated workflows (connected to your business systems) can reduce the cost of packaging processes and shorten lead times.

Get rid of the tedious and error prone manual copy and paste workflow. Automating artwork creation and replication management can avoid errors and speed up the process. Managing sizes, styles, and languages is easy.

Automation Engine

Aiyi has set a new standard for the automation of the pre press process of packaging. It is a modular workflow server with a dynamic workflow that is easy to set up and operate. The automation engine can be fully integrated into any business system.

Automation engines can improve efficiency and productivity, and save time and money. No matter which standard is adopted, the automation engine is an excellent tool for printing professionals to deal with daily challenges, which can improve quality, reduce errors and reduce process costs.

The automation engine is an extensible and easy-to-use client server architecture, which is applicable to any type of client software. The production schedule can provide feedback to MIS or ERP system.

WebCenter

Netsun is a powerful online packaging management platform, which can manage business processes, approval cycles and digital assets 24 hours a day. This network-based secure collaboration platform is convenient for users to manage projects, check, comment and approve files. The flexible and secure centralized network data center is applicable to all packaging assets of a brand, including structural lines, finished documents, images, signs, pictures and other packaging elements. Network based storage can improve efficiency and enhance asset reuse.

Netsun can simplify and control the complexity of packaging brand execution. Finally, the approval process managed by digital signature will shorten the time to market and promote cooperation among suppliers around the world. Netsun is also a channel to third-party systems (PLM, DAM, ERP, MIS).

Esko's packaging processes and management tools are available 24 hours a day, even on mobile devices.

Dynamic Content Engine

Dynamic design engines make content management easier. Single packaging design rapidly evolved into multiple versions. A product has many variants or brand extensions, and these variants need to provide localized versions for the global market. The dynamic design engine is an online solution that reduces the time to market by streamlining the text management process during content creation and design. All variants need to be localized for the global market.

Color management and output

Always get bright color effect

Everyone in the packaging supply chain wants to get the right color at once. Successful color management does not only involve the period before printing. The key to effective color management is communication. The entire production process needs to transfer accurate color information. The whole process from the brand owner's determination of a color to the designer's first creation to printing: barrier free and error free color communication will pave the way to success.

Proofing becomes easy

ASK Proofing Solution is applicable to all kinds of popular inkjet equipment. It can ensure the perfect match between printing and proofing. FlexProof/E includes a lot of advanced functions, such as dot proofing, printing dot gain matching (to simulate flexographic highlight color separation) and proofing for wide gamut printing.

Consistent high-quality output

You want RIP to achieve fast, consistent, and high-quality output. Esko's output solutions adopt open industry standards and have very strong compatibility. Its workflow and equipment are independent. It is applicable to existing and future similar equipment, providing an unparalleled growth path and facilitating penetration into different market areas.

Advanced screening technology

The ASK output solution adopts special advanced flexographic and lithographic printing screening technology. RIP can be used for high-definition flexographic printing (flexographic printing), concentric circle screening (offset printing) and non screening TIFF output to intaglio printing cylinder engraving.

Color Engine

The color engine is a central color management server and database, equipped with patented spectral chromatography technology. The color engine has unique spot color processing capability, providing consistent integrated color management from design to final printing.

Equinox

Yifen is an integrated solution to implement multi-color printing and wide color gamut printing in packaging and commercial printing environments. Esko patented overprint model provides support for multi-color ink characteristic curve in a unique way.

Imaging Engine

The image engine is a kind of RIP. Whether traditional or digital image and printing equipment, the image engine can generate high efficient output files with consistent quality.

Screening

Esko has the most extensive halftone screening technology, each of which has been optimized for a specific printing process. For example, concentric screening is an innovative and well tested halftone dot technology for lithography. HD flexographic printing and full HD flexographic printing screening are flexographic printing

New standards for printing.

Esko's unique patented color technology ensures that brand managers are provided with accurate, consistent and repeatable brand colors, which can be reproduced on any material and using any printing technology.

FlexProof/E

Workflow independent proofing solution. FlexProof is an ICC compatible solution for providing high-quality and consistent digital proofing.

Additional Output Tools

The package software 1 2 includes additional bitmap browsing tool (BitmapViewer), bitmap editing tool (FlexoPerfection) and dot gain control tool (PressSync).

PantoneLIVE

With PantoneLIVE (through X-Rite Pantone), digital brand colors are stored in a secure centralized cloud platform. Brand owners, designers, production staff and all other people in the supply chain can obtain brand colors from it anywhere in the world. Package 12 fully supports PantoneLIVE. The color engine can connect to the PantoneLIVE database and download the selected spot color spectral curve. These spectral curves can then be used throughout the workflow.

The software package 12 has more functions

Software package 12 is not just a combination of different software. As an integrated terminal to terminal solution of ASK, it can improve production efficiency and shape the future development path.

Packaging management: Through Netsun, the package software 12 can provide a web-based packaging management system with excellent performance. Netsun is a core packaging process tool for collaboration, approval, project management, process management, asset management and reporting.

Overall solution for packaging design and prepress production: The structural design software ArtiosCAD and Studio in the package software 12, as well as prepress editors ArtPro, PackEdge and DeskPack, are powerful tools for operators to create and prepare drawings and designs. Intuitive 3D tools and interaction with automated production processes can improve quality and productivity.

Integrated color management: The package software 12 supports PantoneLIVE and is equipped with patented overprint modeling technology, which can provide spot color support for packaging and label workflow.

Unique workflow automation: The automation engine 12 is a workflow that is easy to learn, use and maintain, integrating all functions of BackStage, Nexus Processor and Odystar. With built-in script support, you can automatically ® llustrator ® Create various jobs in. Be able to establish and manage dynamic workflow for the operation of small and medium-sized enterprises and large enterprises (multi-point).

High quality output drives business development: The package software 12 has advanced image imaging and screening technology, which significantly improves the quality of digital printing, flexographic printing, lithographic printing and intaglio printing. For commercial printing users, the software package 12 also provides a powerful workflow automation tool and integrates with the online approval platform, project management tools and MIS system. Nexus and Odystar originally have functions that are integrated into a single automation engine platform. They also have open JDF integration functions that can integrate any third-party software.

Reliable customer service is the key to business success. ASK is committed to providing excellent pre installation, installation, integration and production support. In addition, we can customize the financing plan according to your needs.

software

and

the

to

packaging

is

can

of

for

printing

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time