Kongsberg Cutting Machine | Market leading dieless cutting and indentation

Product Details

Kongsberg

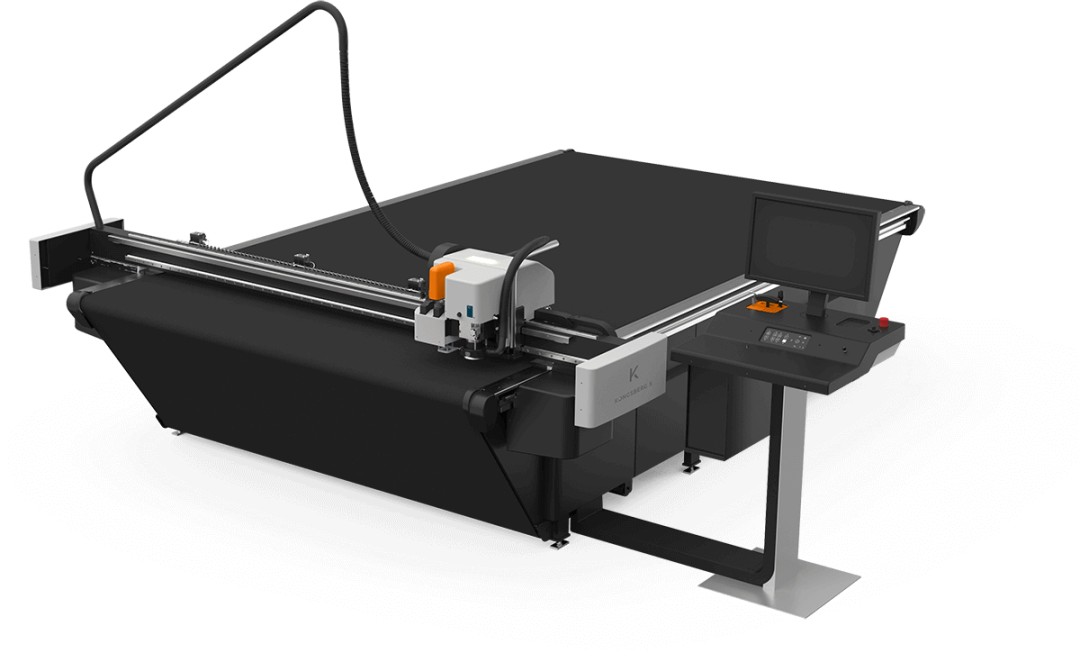

In this era of rapid changes in technology and commerce, the flexibility and development of equipment to adapt to the future has become a top priority. Kongsberg digital cutting table has a variety of tools, which can cut, indent, half cut, milling cutter, drawing and other processing for various packaging and advertising display materials. Kongsberg is the most diversified digital post press processing equipment on the market. With Kongsberg, you can safely invest in the tools you need today and easily upgrade with the development of your business. Add new materials and tools, new applications or greater capacity at any time to ensure your ability to expand and enter new market segments.

Comparison between KONGSBERG and competitors

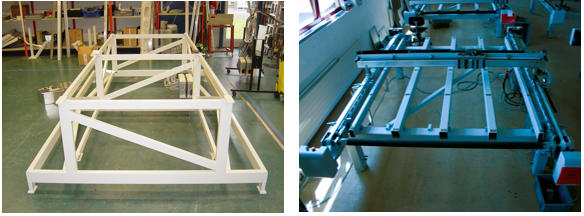

Infrastructure

One step ahead of others. Kongsberg cutting table is the crystallization of more than 50 years of technical expertise and innovation. The basic design is the embodiment of Compaq's value, ensuring high quality and durability.

-Kongsberg: The substructure is designed as a bridge, using a welded steel bar supported diagonally. (Left picture)

-Other competitors: During the installation process, multiple assemblies were installed, with four legs and no diagonal support. (Right picture)

-User value: vibration is the main factor affecting product quality and mechanical durability. The design of Compaq minimizes vibration and provides stability of the machine.

Table top design

High tech table, integrated, durable, can improve production efficiency

-Kongsberg: Factory integrated steel, aluminum and epoxy sandwich panel worktops with high strength and easy adjustment, unique Mapping function, completely flat independent worktops, highly durable, tested before delivery, calibrated and assembled for the vacuum suction area of sheets (left figure)

-Other competitive products: sliced boards, the frame fixed with bolts is leveled with leveling pins, and the plastic/aluminum laminate table top is mainly assembled at the customer's site for the vacuum suction area of coiled materials (right figure)

-User value: The cutting machine table produced and tested in the factory provides processing consistency. Less operation and maintenance means more work is produced every day, extensive material adaptability, and durability of the table make it possible to produce more extensive and higher value work.

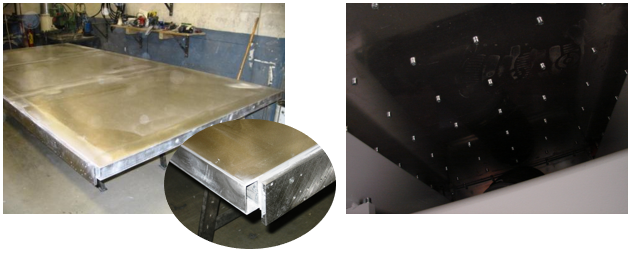

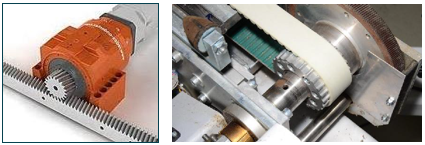

drive system

Forced to choose belt drive, limiting customers' production choices and affecting customers' income

-Kongsberg: The rack and pinion transmission system ensures the speed, durability and strength of the machine. It can easily drive the machine to process high-density or heavy thick materials, with almost zero failure rate. Multiple machines have been used for more than 20 years, with reliable dynamic repeatability (left figure)

-Other competitors: belt/steel belt drive system, based on the technology of pen plotter, power or speed: choose one from the other, it can process optimized light and thin materials, but cannot process heavy or high-density materials directly sprayed by UV printer, with low dynamic repeatability (right figure)

-User value: The production speed increases the number of daily operations, and the maintenance downtime is reduced. Greater flexibility of materials to produce high value-added jobs

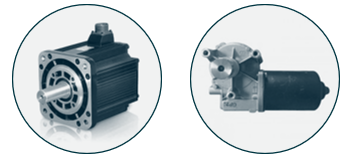

Drive motor

Regardless of the thickness of the material and the tools used, the double side drive motor can ensure the machining accuracy.

-Kongsberg: dual, synchronous, drive motor, double side drive of beam. Greater power and acceleration. Greater cutting stability, high density, and excellent cutting effect of thick materials (left picture)

-Other competitors: single drive motor, single side drive of beam. Only light and thin materials can be processed, and the cutting effect of thick and heavy materials is poor (right picture)

-User value: High power, fast speed and stability enable more work to be produced every day. With the support of high-density and thicker materials for UV printing, more high-quality and cost-effective work can be produced.

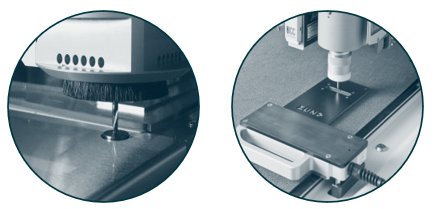

Depth control

Table leveling provides significant labor and maintenance savings

-Kongsberg: The tool height is automatically measured. The leveling process of the cutting machine table provides accurate real-time updated level data. The average measurement time is 10 seconds. The accurate automatic z control in the processing process (left figure)

-Other competitive products: the tool height is measured manually, the table level data is fixed, and the average measurement time is 30 seconds. When the blade or milling cutter is replaced, the machine will not automatically record, and the recording must be started manually (right figure)

-User value: automatic measurement reduces operator time. Less adjustment time means more work is produced every day. The real-time table leveling function adapts to a wider range of work, thus promoting income increase

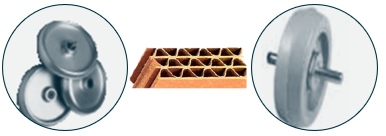

Downforce

High quality corrugated indentation effect makes it competent for heavy corrugated work with high profits

-Kongsberg: under the downforce from 220 N (X series) to 500 N (C series), the maximum pressing wheel is 150 mm, which can be used to press lines on three, five or seven layers of corrugated paper (left figure)

-Other competitors: only about 200 N downforce, maximum Ø 60mm pressing wheel, the indentation effect on thick corrugated paper is not satisfactory (right picture)

-User value: single indentation on corrugated paper can shorten the production time, and high-quality corrugated indentation effect can make it competent for heavy corrugated work

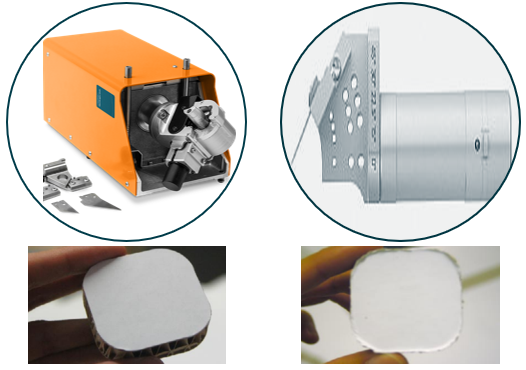

Vertical corrugated paper processing

The unique variable angle tool performs beyond your imagination

-Kongsberg: C series extremely solid tool rack can withstand high work, X series convenient plug-in tools, and the latest variable angle tools can cut multiple angles at one time without changing the tool (left figure)

-Other competitors: plug-in tools with standard tool heads. Manually adjust the angle V slot tool, with low-quality cutting effect, which requires several times to reach the standard (right figure)

-User value: the latest variable angle tools greatly shorten the processing time, and different angles can be completed at one time

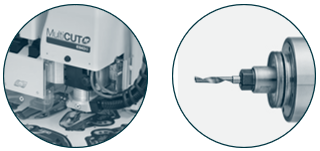

Milling cutter

High power milling cutter provides customers with more choices and creates more value

-Kongsberg: High power (HP) motor spindle speed up to 60000 rpm, 3kw power, water-cooled, durable, can always operate under high load, 6mm or 8mm milling cutter optional, up to 3 times the milling cutter processing speed (left figure)

-Other competitors: standard motor spindle speed 50000 - 60000 rpm, 1kw power, 6mm milling cutter (right figure)

-User value: the power and milling cutter size guarantee 3 times of the processing speed, and the larger power and water cooling system enable it to be competent for materials with higher added value and more difficult work

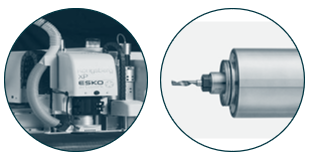

Milling cutter operation

Automatic tool identification and measurement provide significant labor savings

-Kongsberg: pneumatically driven collet, easy to replace milling cutter (no tool required), automatically measure the tool height before the next step of work (left figure)

-Other competitors: To replace the milling cutter manually, remove the milling unit, place it on the table, unlock the tool collet, insert the milling cutter, manually tighten the collet, reinstall the milling unit, place the measuring plate on the table, measure the tool height, and put the measuring plate back. Be careful, the machine is in working condition throughout the process! (Right picture)

-User value: significantly save time, can quickly change and measure tool height, make changes between work types and materials faster, so as to support rapid turnover of customer production. High value, fast turnaround work can often be sold at a higher price.

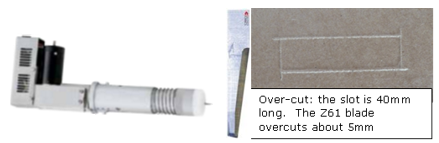

Vibrating knife tool

The power of Konsbo vibrating knife is higher, which can adapt to the work with higher intensity

-Kongsberg: There are two versions of electric tools: standard type, which can be used on various models, providing fast general cutting and the best choice for cutting standard quality corrugated cardboard; High frequency type, using sharp blade, cutting speed 25-30 meters per minute; The best choice for high recycled corrugated board and foam board, automatically edit the cutting direction and eliminate over cutting

-Other competitors: electric drive: fast, but only for lighter materials. Pneumatic drive, can cut thick and heavy materials, but at a slower cutting speed: - maximum 6 m/min sharp blade- highest. 25m/min flat blade, which produces over cutting when cutting with sharp blade, and reduces the quality when cutting arc. If the air pressure fluctuates, the frequency and cutting depth will change

-User value: fast cutting speed, no need to adjust the frequency and cutting depth. The flexibility and speed of work can shorten the delivery period and increase the efficiency.

Camera positioning system

High performance camera positioning system improves work efficiency and reduces unnecessary errors

-Kongsberg: iPC control software, multiple positioning modes, high-performance LED camera, which can be used for transparent or highly reflective materials, read two-dimensional codes, and automatically retrieve cutting files, making operation easier (left figure)

-Other competitors: products of other agents (right figure)

-User value: The high-performance camera improves the operator's ability to automate the workflow. The complete function integration can handle additional work and increase income

KONGSBERG Breakthrough Automation

Kongsberg Feeder and Stacker

A series of impressive innovations will improve the performance of digital finishing operations to the industrial level.

The Kongsberg Automatic Feeder and Stacker are the perfect way to increase productivity and give your business a competitive advantage.

This is an easy to use tray to tray solution. It feeds corrugated paper core board and plastic from the tray quickly and accurately with a feeding cycle of 2 continuous material flows per minute. There is no delay in loading and unloading the boards from the table, so the table is optimally utilized.

The feeder and stacker were developed for the Kongsberg X and Kongsberg C workbenches. Plate feeder (i-BF) and stacker (i-MF) can be purchased separately. Optional reel feeder and expansion table are also available.

Robotic material porter

Robotic material handling machine is a high capacity material handling system. It is perfectly matched with Kongsberg C66R cutting platform and used in combination with 2 or 4 stacks of materials to provide completely unattended operation. Robotic material handlers improve productivity while reducing operator time.

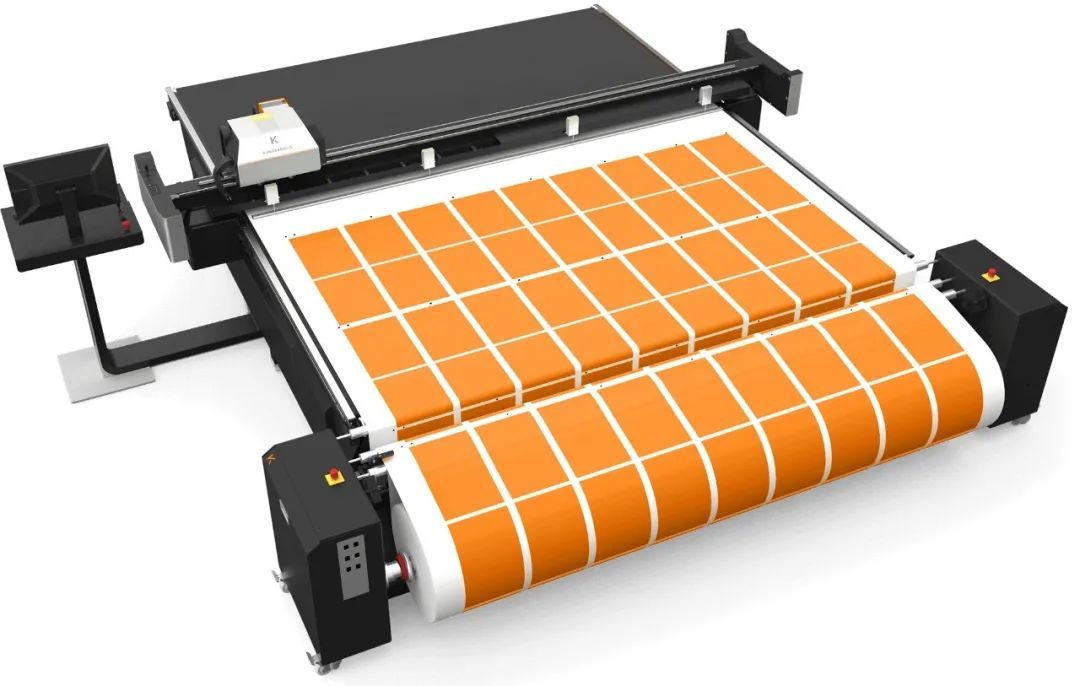

Electric drum feeder for soft label operation

Kongsberg electric drum feeder is a wide range drum feeder, which provides active material feeding for Kongsberg C64 cutting table. With the Kongsberg electric web feeder, you can eliminate the inaccurate cutting of soft label materials caused by wrinkles, stretching deformation or imperfect rewinding of the web, even on the most challenging and elastic substrate.

Kongsberg electric drum feeder is the only solution in the soft label industry that can ensure the perfect cutting effect on tensile materials; From the first cut to the end of the drum.

Combined with Kongsberg take-up device, the electric drum feeder can realize real coil to coil production.

Flexible material coiling device

The Kongsberg take-up device for flexible materials makes the coil to coil workflow easier. The device makes it very simple to complete the digital printing operation on the reel and collect waste.

The receiving unit is easy to install and is suitable for any Kongsberg worktable equipped with a belt feeding system. The device is easy to operate and can be easily removed when not needed.

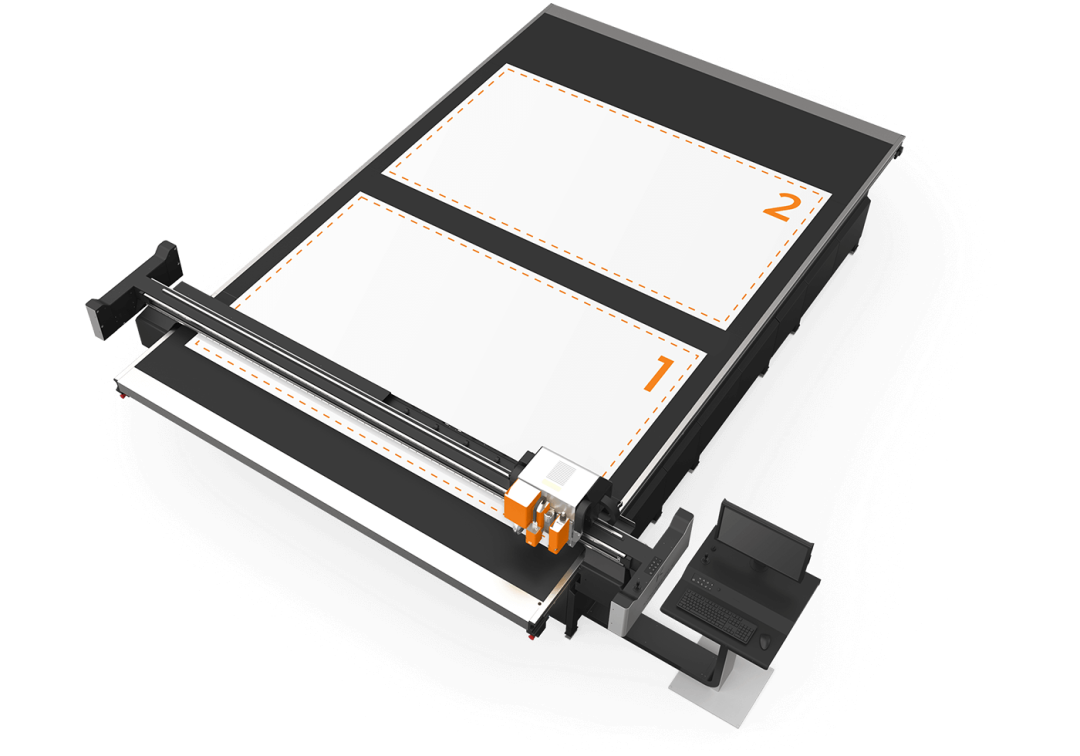

Multi regional production: release real power

Kongsberg table can independently use two working areas: multi area finishing.

This is particularly useful for large Kongsberg tables. When one area of the workbench is running, the operator can set another area by cleaning the finished product and loading new paper. When the operator is working and preparing one area, the machine is working in another area.

Perfect fit for various applications

cutting

the

and

of

is

to

kongsberg

can

with

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time