EXact 2 Series New Generation Non-contact Portable Color Difference Meter | X Redefines Color Measurement

Product Details

In order to adapt to the modern production environment, printers, packaging service providers and ink suppliers all put forward higher requirements for color control capability and efficiency verification required by customers. Although portable color measuring instruments can usually meet most requirements, their performance is often uneven. Independent spectrophotometer has become the yellow flower of yesterday, which can neither lead you into the future of color measurement nor ensure excellent quality, but the appearance of eXact2 is impressive.

As a new generation of color measuring instrument, eXact2 can meet the demanding requirements of printing, ink and packaging professionals. Its design is intelligent and precise, and it pioneered Mantis video target positioning technology. No longer worry about color tolerance, base material cost, material shortage, new training, slow measurement speed and slow instrument response. With eXact2, we redefined color measurement to create a highly integrated and innovative workflow that maximizes performance and efficiency.

Interconnection solutions are fast, accurate, simple and easy to use. They support different substrates, simplify work processes, reduce waste, liberate production capacity, and improve efficiency. They are favored by today's professionals.

Functional advantages

Always accurate measurement and positioning: with the help of high-resolution camera and Mantis video target positioning technology, what you see is what you measure.

Reliable detection of color chips: The digital magnifying glass function of eXact2 supports dynamic scaling, captures and detects correct measuring points without measuring printing defects, and saves measured images.

Easier menu navigation: eXact2 is ergonomically designed with an adjustable tilt display and intuitive "click or double click" operation menu to speed up work and reduce human errors.

Fully reduce ink pollution: eXact2 uses the non-contact measurement principle to measure scraping and proofing without touching the ink.

Work freely: With eXact2, you can directly carry out the color measurement process without connecting a console or computer with Wi Fi function.

Management workflow: eXact2 supports viewing the quality results of ColorCert jobs directly on the device, and can simplify the ink workflow by integrating InkFormula software (IFS).

Direct access to color standards on the device: eXact2 supports retrieval of preloaded Solids, Neons, and Pastels Pantone color library, and can connect to PantoneLIVE color library to obtain thousands of colors and cover various substrates.

Switch between single point and scanning mode: With the integrated scanning wheel, you can switch from measuring a single color chip to scanning a color band with a simple click, and use the built-in camera to preview and identify the color band.

Managing the entire instrument group: With the X-Rite Link operation panel, you can obtain information about equipment health and service history, and remotely deploy firmware updates, color libraries, and standards for the entire instrument group.

EXact 2 Function Comparison

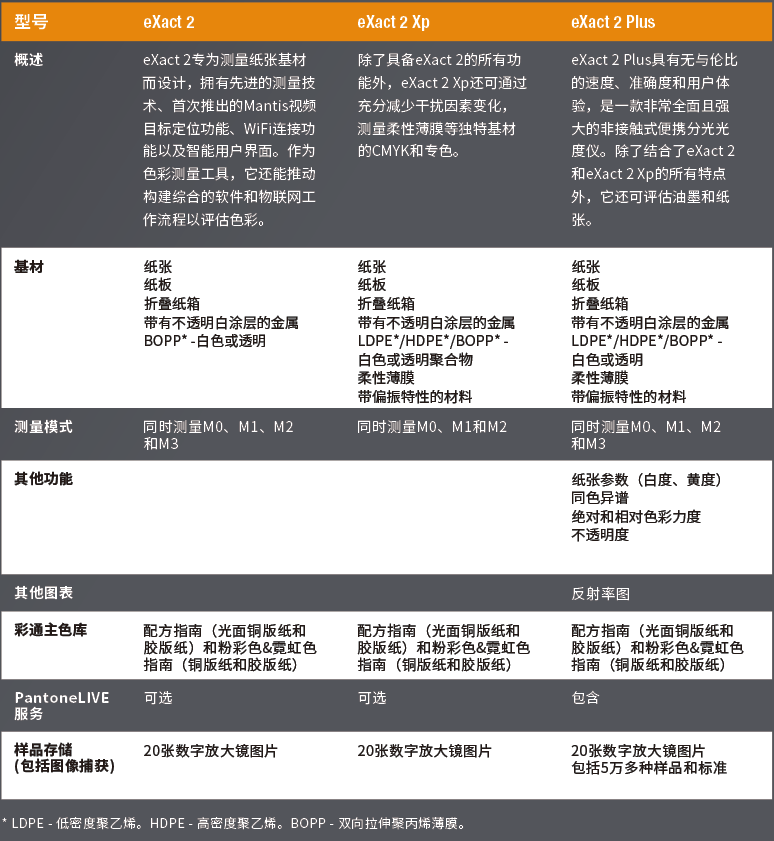

The eXact 2 series is available in three models: eXact 2, eXact 2 Xp, and eXact 2 Plus to help you choose the right model.

EXact 2 Feature Comparison

EXact 2 is specially designed for measuring paper substrate, equipped with advanced measurement technology, groundbreaking Mantis video target positioning function, WiFi connection function and intelligent user interface. It is not only a color measurement tool, but also an important driving force to promote the integration of software and the Internet of Things workflow to evaluate color.

1) Measurement mode: eXact 2 can measure M0, M1, M2 and M3 simultaneously

2) Sample storage (including image capture): 20 digital magnifying glass pictures

3) Caitong basic color library: eXact 2 preset Caitong color guide (glossy coated paper and offset paper) and pink&neon color guide (glossy coated paper and offset paper)

EXact 2 Xp Feature Comparison

In addition to all the functions of eXact 2, eXact 2 Xp can also measure CMYK and spot color of unique substrates such as flexible films by fully reducing disturbance.

1) Measurement mode: eXact 2 Xp can measure M0, M1 and M2 simultaneously

2) Sample storage (including image capture): 20 digital magnifying glass pictures

3) Caitong basic color library: eXact 2 preset Caitong color guide (glossy coated paper and offset paper) and pink&neon color guide (glossy coated paper and offset paper)

EXact 2 Plus Feature Comparison

With unparalleled speed, accuracy and user experience, eXact 2 Plus is a full-featured and powerful non-contact handheld spectrophotometer. In addition to combining all the characteristics of eXact 2 and eXact 2 Xp, it is also possible to evaluate ink and paper.

1) Measurement mode: eXact 2 Plus can measure M0, M1, M2 and M3 simultaneously

2) Base material: eXact 2 Plus also provides reflectivity curve to evaluate the reflectivity characteristics of reflective and metal effect base materials

3) Other functions: Unlike eXact 2 and eXact Xp, eXact 2 Plus can also measure paper index (whiteness, yellowness), metamerism, relative color strength and opacity

4) Sample storage (including image capture): eXact 2 Plus can save 20 digital magnifying glass pictures and more than 50000 samples and standards

5) Caitong basic color library: eXact 2 preset Caitong color guide (glossy coated paper and offset paper) and pink&neon color guide (glossy coated paper and offset paper) are different from other eXact 2 models. eXact 2 Plus also includes a one-year PantoneLIVE specific color library license

Application scenario - commercial printing and packaging service provider

With eXact 2, only one set of equipment can measure paper and flexible film substrate simultaneously. Built in scanning function and intuitive design shorten color measurement time, reduce substrate and ink waste and improve printing efficiency.

With eXact 2, quality standards will be met 17% faster than similar solutions, and even the most demanding customers will be convinced. The device is equipped with a "click or double click" touch interface and a built-in high-resolution camera. It supports MantisTM video target positioning technology and the original digital magnifying glass function, allowing users to enlarge the measurement area, check color blocks, analyze dot gain, read the printing plate and even save color measurement images for quality verification.

EXact 2 also offers advanced color matching and quality control tools and reporting capabilities. Through the integration of ColorCert software, ColorCert job results can be displayed instantly without using other computers and speeding up the hit speed of color standards.

Application scenario - ink supplier

EXact 2 is a handheld measurement solution tailored to your unique needs, which allows you to communicate color data with printers and packaging service providers and quickly and accurately formulate formulas.

Because of the non-contact measurement, it can prevent the wet ink from being dirty and avoid repeated measurement. With a switchable polarization filter, only one set of equipment is needed to prepare and verify ink for a wide range of substrates such as flexible films. EXact 2 can simultaneously measure all the measurement conditions specified in ISO 13655:2017 standard: M0, including ultraviolet ray; M1 (method 2), D50; M2, eliminate ultraviolet ray; M3, polarization. This means that one device can cover all measurement states, independent of the type of substrate, and there is no need to worry about equipment compatibility.

Through close integration with X-Rite's InkFormula software, color matching performance can be improved and proofing requirements can be reduced, thus speeding up color development. With the original formula function, you can accurately prepare the ink color once, saving time and cost, and reduce the overall ink inventory by recycling the remaining ink and printing machine rework.

With seamless software integration, Wi Fi quality control and built-in process control tools that support G7, PSO and Japan Color standards, the eXact 2 portable spectrophotometer can help printers, ink chambers and packaging service providers accurately reproduce CMYK and spot colors.

Imaging Technology Behind Mantis Video Target Location and Digital Magnifier

Using eXact ™ 2 on-board high-resolution camera and non-contact imaging function can measure the correct position every time. With this intelligent infrastructure, you can use the "double click or less" touch screen interface, Mantis ™ Video positioning technology, digital magnifying glass function and seamless workflow integration will increase the speed of meeting quality standards by 17%.

Mantis video target location: WYSIWYG

EXact 2 uses patented Mantis high-resolution imaging technology to capture visual images of precisely measured areas. Compared with the traditional target positioning technology, Mantis is more accurate for measurement, because it can provide a virtual preview of the precise point where the spectrophotometer captures the spectral reflectance of the sample, and will not limit the size of the object to be measured or cause excessive illumination on the color block surface.

In addition, eXact 2 uses virtual target positioning technology to illuminate the entire surface and capture accurate measurement points and dimensions. Therefore, the measuring point is very accurate without any occlusion. Mantis is suitable for both spot and scan modes. With the comprehensive scanning function of internal pattern recognition, it can read a series of color blocks in a single scan, thus significantly improving the speed of color block measurement.

Digital magnifier: accurate identification and detection of color patches

The high-resolution camera of eXact 2 can also provide dynamic zoom function of digital magnifying glass during color block detection. With a zoom capacity of up to 10 times, the operator can enlarge the device screen during or after the measurement to identify leaks, dirt, etc., and capture images for later tracking to prove the measurement quality.

By using a digital magnifying glass on the registration line, operators can verify the registration of cyan, magenta, yellow and black plates. The zoom function helps to more accurately verify whether the color overflows the black line.

color

and

the

of

exact

to

can

measurement

with

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time