GMG Network Digital Proofing | Empowering Printing and Packaging Enterprises to Meet New Challenges

Release Time: 2022-11-30 18:53:54.245

Preface

Monday, February 10, 2020, was an ordinary day, but the COVID-19 epidemic made it extraordinary. Today is the official resumption of work after the Spring Festival holiday. Everyone is concerned about how to do a good job in epidemic prevention and control, and how to ensure orderly work even when not all personnel are in place.

A printing factory contacted us and asked: "Is there a good way to allow production personnel to create, edit, and monitor proofing jobs on their own computers?" This can prevent excessive contact between people on one item, save time costs, and improve work efficiency. I originally thought of using remote desktop, but the client said that there are limited personnel and wants to improve work efficiency. If possible, it would be best if several users could use it simultaneously. Then I suggested that they consider using GMG ColorProof WebClient.

Many friends may not be familiar with GMG ColorProof WebClient. I will take this opportunity to give a brief introduction to GMG ColorProof WebClient.

GMG ColorProof + WebClient Network Client Technology

GMG ColorProof WebClient is an important network client technology that makes proofing simpler and more convenient for many users. It allows users to submit, edit, and monitor jobs from any PC or Mac computer within the company. With WebClient, GMG ColorProof users have the ability to create, edit, and monitor proofing jobs on any PC or Mac computer within the company network for the first time. Moreover, several users can use ColorProof simultaneously. In particular, the configuration of spot color channels is also facilitated and accelerated through WebClient, and the effects of spot color modifications can be viewed in the visual job preview.

With the GMG ColorProof WebClient network client function, users can run GMG ColorProof from their Mac or PC computers. Besides, what value will users gain from it?

How to simplify the proofing workflow?

Multi-user support

Multiple users can use the WebClient network client at the same time, so ColorProof is more efficient.

Remote connection

Each operator can track jobs in ColorProof from their own Mac and PC computers. You can see which jobs are printing and which jobs have been printed. Checking the ColorProof job status no longer requires a VNC virtual network computer or remote desktop.

Create jobs

Users can create jobs (continuous tone files or 1-bit files) by dragging and dropping files into the ColorProof hot folder (visible in the WebClient user interface).

Modify spot colors

WebClient allows assigning spot colors to each image channel. The lack of spot color assignment is the most common problem in manually editing jobs. Now this task can be easily accomplished through WebClient.

Job preview

WebClient displays a thumbnail preview image to help identify jobs and view the effects of spot color modifications.

Assemble your favorite hot folders

Each user can create their own list of favorite hot folders, marked with special icons. Users can easily create jobs by dragging and dropping. This avoids browsing a large list of hot folders to find the correct file.

Keep, cancel, print, and reprint

In the WebClient interface, you can keep, cancel, print, or even reprint queued jobs in the history list.

Track printer status

Each operator can check the printer status, so it is easy to see if the printer is out of paper or ink. A link page for the internal status of the printer provides more detailed information.

Work in a browser or independently

WebClient can be opened in a web browser such as Firefox, Internet Explorer, Safari, or Google Chrome, or launched from the Windows Start menu or Mac Dock like other applications, without requiring a browser.

Multiple ColorProof, one client

WebClient can be used to monitor multiple ColorProof programs. You can view jobs and printer status for up to three different programs in one window.

The GMG ColorProof WebClient network client function can help printing companies reduce communication costs, improve and shorten proofing preparation time, and accurately achieve goals. It helps printing companies achieve profitability and thus improve their core competitiveness. It helps printing companies transition from manufacturing to intelligent manufacturing.

Some other functions of GMG ColorProof

Faster RIP speed

A new "Fast RIP" option has been added. Multi-threading technology utilizes multi-core CPUs to make RIP faster.

Excellent gray balance

The GMG digital proofing system can handle gray balance excellently, making the samples more accurate.

Powerful spot color processing capabilities

Spot color simulation has always been a challenge in packaging proofing. GMG's powerful capabilities in this area have been fully recognized by the market.

Simplified calibration package

One-time calibration for multiple uses. Production proofing is different from traditional printing proofing. When calibrating each type of paper, the printing mode and resolution are very important. Production proofing, such as Epson 80680 series printers, will have different calibration needs. GMG calibration packages are classified according to the model of the production printer, similar combinations of printing media and printing modes. Each calibration package is based on a calibrated reference print setting, including all printer settings, so it can be applied to all jobs after one calibration without affecting quality.

Easier to create jobs with white ink/silver ink/varnish

New features have been added to the manual job manager: print layers. For example, a printer with special inks, such as white ink, varnish, or silver ink, can now automatically generate multi-layer printing, using at least one special ink in one job.

Include and remove paper simulation

Usually, proofing programs include paper simulation to achieve accurate colors, but sometimes the appearance of the actual production paper differs from the proofing paper. GMG ColorProof has added a paper color option to turn off paper color simulation when generating proofing curves.

GMG Proofing Solution

GMG ColorProof

A world-class solution for accurate continuous tone proofing

For years, GMG ColorProof has been the recognized standard solution for efficient and stable contract proofing.

Plug & Proof – simple, efficient, and fast digital proofing, requiring no expert knowledge, with significant spot color simulation and support for extended color gamuts.

GMG ProofControl on board – stable quality control, globally recognized contract proofs, hot folder technology for efficient automation, and flexible integration with other systems.

Built-in Raster Image Processor (RIP), using original Adobe PDF Print Engine technology, load balancing and nesting technology for maximum production efficiency and minimal material usage.

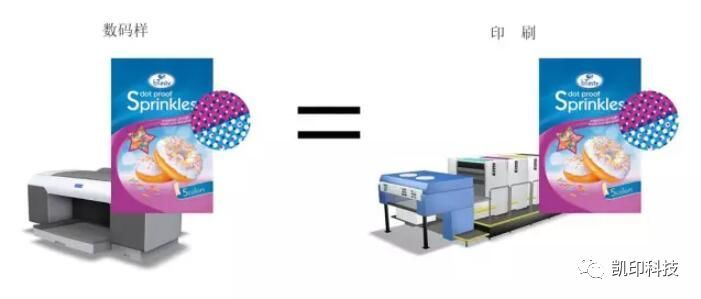

GMG DotProof

Color-accurate halftone proofing with true contract proof quality

Further expanding GMG ColorProof functionality:

Accurately simulates raster structures to reproduce printing halftone effects

Achieve the same halftone effects in the final printing stage

Control color accuracy and provide halftone effect simulation in one software, providing a stable preview of actual production data

GMG FlexoProof

A stable packaging/flexographic proofing solution that meets the needs of color and substrate texture simulation.

Unique characteristics of the packaging market, simple solutions for complex areas, the preferred choice for packaging prepress experts to communicate color for many years.

More features with accurate simulation of packaging printing effects.

Up to 64 separations, white ink printing, all controllable.

Register offset and special substrate texture simulation - even corrugated board.

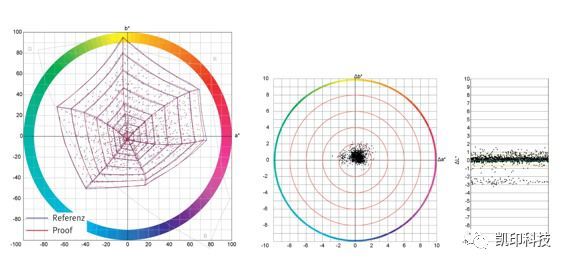

GMG ProofControl

Quick proof check within seconds

Scan control strips, check color difference values and their changes as a basis for color evaluation, or use this to ensure stable proofing quality.

Fogra standard control strips, custom control strips, and spot color strips dynamically generated for specific job color control.

Guaranteed stability - fast, intuitive, almost fully automatic when using built-in printer measuring instruments.

Self-adhesive labels or detailed reports provide maximum transparency for all project partners.

GMG OpenColor

Packaging spot color printing characteristic curve creation, unprecedented efficiency and stability.

The only tool in the world that can turn GMG ColorProof into a true printing simulator.

Simulate the colors of printing - including spot color overprinting, spot color gradients

Patented spectral data process, efficient multi-channel characteristic curve creation, production parameters can be set according to actual settings

As a central database, obtain consistent color on any number of proofing systems - requires GMG ColorProof

Only a small color strip needs to be loaded in the previous print to obtain the device curve, without the need to print a separate color chart. This greatly reduces the time to make curves and reduces the waste caused by printing color charts.

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Kaiyin Technology - Awarded "Specialized and New Enterprise"

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen municipal preliminary examination, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements. It marks another significant step forward for Kaiyin Technology in technological innovation and development in its specialized field.

MeasureColor and eXact AutoScan help you achieve exceptional print quality.

Achieving stable print quality hinges on your ability to control dot gain—a critical yet often overlooked variable. Dot gain significantly impacts color accuracy, image sharpness, and overall visual performance, particularly in packaging printing and workflows involving expanded color gamuts. With MeasureColor, printers can access advanced tools that enable them to effortlessly monitor, manage, and optimize dot gain in real time—eliminating the need for subjective guesswork.

On the journey toward higher precision, greater efficiency, and more sustainable development in the printing industry, the plate-making stage has always served as a crucial link—connecting the past with the future. As numerous printing companies choose among the dazzling array of CTP (Computer-to-Plate) equipment available, one well-known name—Kodak—often finds itself at the center of attention with its CTP solutions.

In manufacturing, even the slightest difference in color can often be the dividing line between high-quality and substandard products. Whether it’s apparel, building materials, cosmetics, or durable consumer goods, consistently accurate colors are not only a pursuit of product aesthetics—they also serve as the cornerstone of brand commitment and customer trust. Achieving this goal is inseparable from powerful color measurement tools—high-performance spectrophotometers.

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time