Kaiyin Technology - Awarded "Specialized and New Enterprise"

Release Time: 2024-04-28 09:00:00.000

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen preliminary review, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements, marking another significant step forward in technological innovation and development in its specialized field.

Specialized and New Small and Medium-sized Enterprises

On December 27, 2023, the Shenzhen Municipal Bureau of Small and Medium-sized Enterprise Service officially announced the "2023 Shenzhen Specialized and New Small and Medium-sized Enterprise List," and Shenzhen Kaiyin Technology Co., Ltd. was honored to be included. This honor is not only an affirmation of the company's long-term unremitting efforts but also a shining footnote to its outstanding achievements.

"Specialized and New" is an honorary award specially established by the state to promote the development of small and medium-sized enterprises, enhance their core competitiveness, and achieve four development goals: specialized operation, refined output, characteristic processes, and novel products. This award comprehensively evaluates and professionally reviews enterprises from multiple dimensions, including business revenue, R&D investment, innovation capabilities, market occupancy rate, and intellectual property rights. The selection of "Specialized and New" small and medium-sized enterprises is an important strategy implemented by the state to guide enterprises towards the "Specialized and New" development path and improve the overall quality and competitiveness of small and medium-sized enterprises. Obtaining this title signifies that Kaiyin Technology has received high recognition and affirmation from the government in terms of technological innovation, market development, and sustainable development capabilities.

The title of "Specialized and New" represents the outstanding performance of enterprises in specialization, refinement, characteristic, and innovation. It is a high-level summary and recognition of the development characteristics of small and medium-sized enterprises. This honor is considered the most authoritative and highest-level honor in the national assessment of small and medium-sized enterprises, symbolizing the pursuit of excellence, enhanced independent innovation capabilities, and core competitiveness of small and medium-sized enterprises.

This recognition as a "Specialized and New Small and Medium-sized Enterprise" is not only an affirmation of Kaiyin Technology's past efforts but also an encouragement for future development. In the future, Kaiyin Technology will adhere to the development concept of "Specialized and New," continuously improve its product system, continuously enhance product competitiveness and improve customer satisfaction, provide customers with better products and services, and contribute positive energy to the high-quality development of the printing and packaging industry and brand color management.

Specialized and New Project - kngColor Prepress Physical Digital Proofing

How to free valuable printing presses from frequent proofing

Compared with traditional printing press proofing, kngColor prepress rapid physical digital proofing has many advantages, such as simple operation, no plate making required, one-time molding, high color matching accuracy, high precision, high efficiency, and low cost, achieving cost reduction and efficiency improvement for printing and packaging enterprises under the new situation.

At the same time, it allows us to avoid many risks, quickly identify problems in prepress, and improve printing quality. The higher the image resolution, the better the printing effect. Kaiyin Technology's rapid physical proofing solution has high precision and speed, and one machine meets multiple printing needs.

Kaiyin Technology's advanced color management technology provides enterprises with color-accurate digital and physical proofing solutions, making communication between brand owners, prepress media, and printing and packaging enterprises more efficient and convenient, while reducing enterprise cost losses, improving the production capacity and equipment utilization rate of enterprise printing workshops, thus achieving energy saving and efficiency improvement, stable quality, and enhancing the market competitiveness of enterprises.

kngColor rapid physical proofing, creating a competitive advantage, improving production capacity, and reducing costs

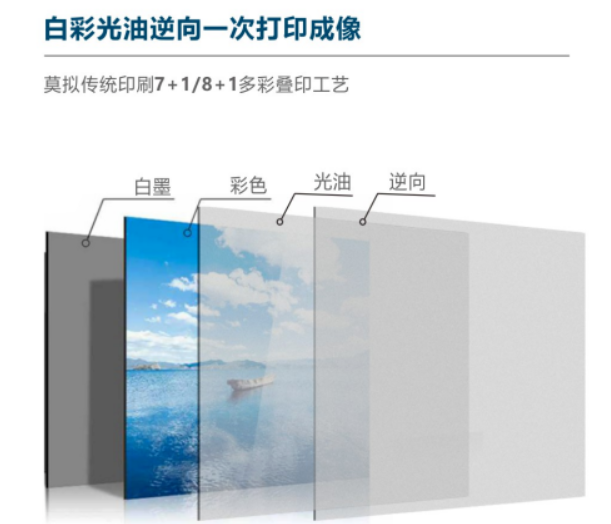

The solution is suitable for rapid prepress physical proofing and is highly compatible with printing. Suitable for small-batch production, high-quality, personalized customized products, scratch-resistant and wear-resistant, with vibrant colors and a wide range of substrates, it can be used in various application scenarios. It can directly proof on coated paper, gray board, white board, CCNB, kraft paper, gold card paper, silver card paper, laser paper, transparent PET and other special materials. CMYK plus spot color, varnish combinations, can achieve white ink, four-color + spot color, reverse, local UV coating full process synchronous printing output.

Simulates the UV reverse effect in traditional printing processes. UV reverse application is a new printing and packaging process that can create different sizes of matte effects on the surface of printed matter. Simulates the local UV coating effect in traditional printing processes, with high brightness, high transparency, and features such as folding resistance and wear resistance. The coated pattern is more vivid, bright, and three-dimensional compared to the uncoated pattern, creating a unique artistic effect.

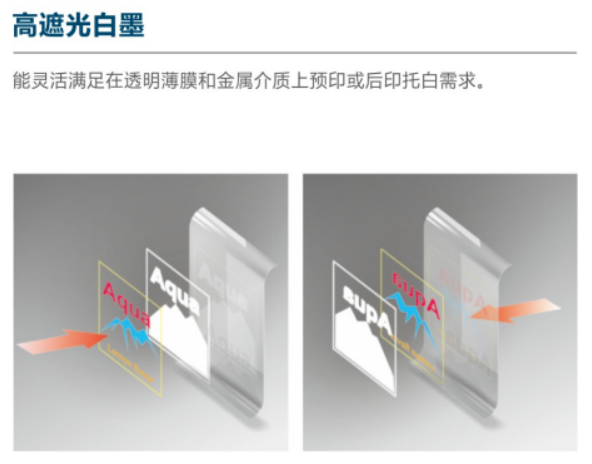

When printing color patterns on non-white materials, the material color will directly affect the color of the color pattern, such as kraft paper, black card paper, red card paper, transparent materials, etc. At this time, it is necessary to use white ink as a base before printing color to achieve the full display of color.

-

High-precision image quality, high color matching with printing presses, wide range of substrates and applications: can print flexible and rigid substrates, with multi-functional cylindrical fixtures can achieve curved surface printing, white ink and varnish can present 3D relief effect, suitable for various applications.

-

Using high-resolution industrial-grade printheads, sturdy and durable, not easy to deform, can continuously provide stable and consistent ink droplet ejection, while achieving high-speed output, sharp text and smooth tone changes, achieving high-quality image output.

With the continuous development of digital inkjet technology and color management technology, the current digital inkjet system can realize the production of most packaging physical models, and can reproduce the actual printing effect on many materials such as white cardboard, gray board, gold and silver card paper, tinplate, aluminum plate, film, and shrink film, and can also be combined with digital hot stamping and digital UV coating for post-press finishing. It can well reproduce the actual printing effect.

A new dimension of packaging proofing, turning predictions into reality

kngColor rapid physical proofing is not only an important basis for printing quality control but also an effective means of efficient communication with customers. The materials and effects that customers want to print can be proofed first. Whether it is a terminal printing and packaging enterprise or a professional prepress company, digital inkjet proofing has already been used. In order to better serve brand customers, printing and packaging enterprises are very necessary to equip professional digital inkjet proofing systems to shorten proofing time, reduce proofing costs, and thus improve the market competitiveness of enterprises and enhance customer stickiness.

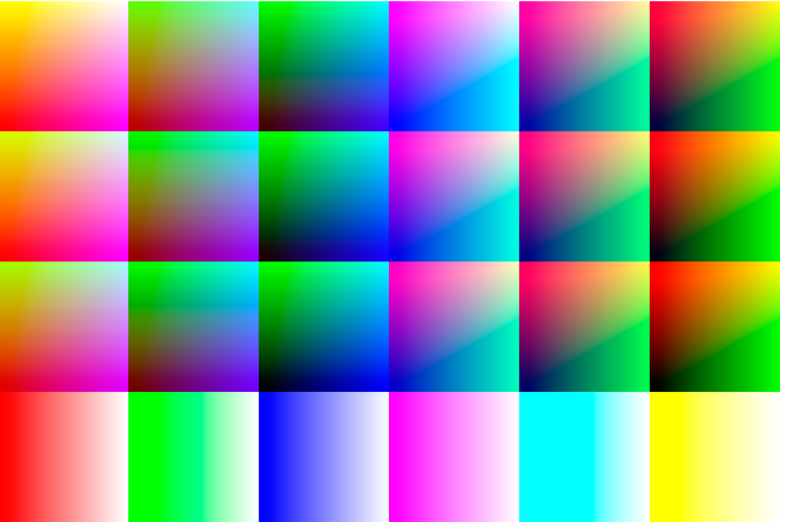

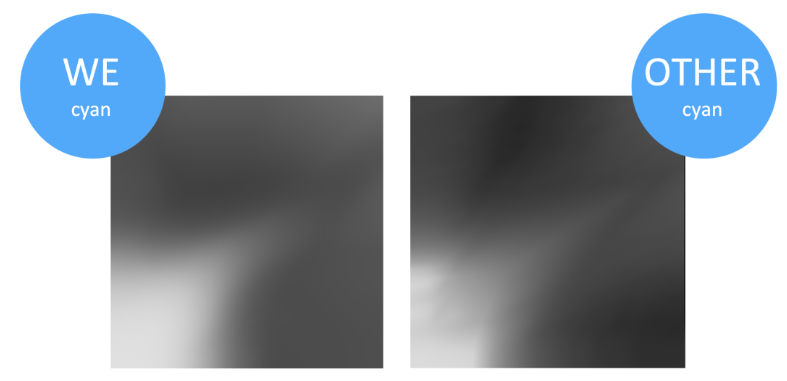

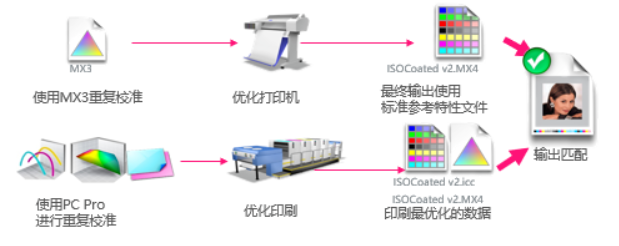

Using professional digital proofing software for color management and matching, digital proofing can achieve what you see is what you get, and pre-press proofing and printing targets can achieve stable color matching; matching targets directly output international standard samples such as G7/GMI/FOGRA. Better color smoothness, accurately predicting highlights, midtones, and shadows. Based on many accurate predictions, the fact is that technical know-how determines everything.

Four-color and spot color reproduction effects are good, whether it is a custom target or an international printing standard; the digital sample color maintains stability and can always remain consistent; the solid spot color simulation is good. Color processing solves spot color gradients, solves four-color overprinting spot colors, solves spot color overprinting spot colors, solves four-color and spot color gradient overprinting, and solves spot color and spot color gradient overprinting.

At present, physical proofing can use actual production paper, compatible with mainstream printing papers such as digital paper, coated paper, gray board, and white board;

Compared with traditional post-press processes, digital post-press efficiency enhancement has obvious advantages, is flexible and variable, improves efficiency, and meets personalized needs; the process is diverse and exquisite, greatly improving product value. It can achieve a high degree of differentiation to meet customers' personalized needs. At present, printing companies' awareness of digital post-press efficiency enhancement technology is constantly increasing, and they also require companies to not only introduce digital post-press efficiency enhancement equipment, but also explore different processes and practical skills, cultivate suitable digital post-press efficiency enhancement technical personnel, and further meet customers' personalized needs.

Advantages of fast packaging physical proofing

-

Realize physical proofing with actual printing materials through paper printing materials

-

Using professional color management software to easily, quickly, and accurately reproduce printing effects, including spot colors and overprint colors, can be well reproduced, realizing true digital proofing

-

The post-digital efficiency enhancement application materials have a wide range of compatibility, applicable to various printing materials, accurately simulating hot stamping, glazing, matte, reverse, etc., to meet personalized needs, and the process is diverse and exquisite

-

Expand the physical proofing you want to do, and quickly make finished products in the form of boxes with digital cutting.

-

Improve production efficiency/save costs

- Fast proofing, physical models, and personalized packaging

- Reduce the frequency of on-machine proofing, improve proofing effect, and reduce costs

- Reduce the plate making or printing time caused by proofing, and release the printing press capacity

- Improve the utilization rate and capacity of the printing press

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Kaiyin Technology - Awarded "Specialized and New Enterprise"

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen municipal preliminary examination, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements. It marks another significant step forward for Kaiyin Technology in technological innovation and development in its specialized field.

MeasureColor and eXact AutoScan help you achieve exceptional print quality.

Achieving stable print quality hinges on your ability to control dot gain—a critical yet often overlooked variable. Dot gain significantly impacts color accuracy, image sharpness, and overall visual performance, particularly in packaging printing and workflows involving expanded color gamuts. With MeasureColor, printers can access advanced tools that enable them to effortlessly monitor, manage, and optimize dot gain in real time—eliminating the need for subjective guesswork.

On the journey toward higher precision, greater efficiency, and more sustainable development in the printing industry, the plate-making stage has always served as a crucial link—connecting the past with the future. As numerous printing companies choose among the dazzling array of CTP (Computer-to-Plate) equipment available, one well-known name—Kodak—often finds itself at the center of attention with its CTP solutions.

In manufacturing, even the slightest difference in color can often be the dividing line between high-quality and substandard products. Whether it’s apparel, building materials, cosmetics, or durable consumer goods, consistently accurate colors are not only a pursuit of product aesthetics—they also serve as the cornerstone of brand commitment and customer trust. Achieving this goal is inseparable from powerful color measurement tools—high-performance spectrophotometers.

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time