Comprehensive interpretation of the latest M measurement mode

Release Time: 2022-12-02 17:18:22.370

What does the new M measurement mode do?

--Successful response to color management of paper containing fluorescent whitening agent (OBA)

Most modern printing and proof paper contains fluorescent brightener (OBA). This additive can increase brightness and improve appearance. The brighteners in modern paper challenge the successful management of color. Therefore, the new standard is conducive to the color management and communication of paper containing whitening agent.

brief introduction

Fluorescent brighteners work by fluorescence reaction. They absorbed invisible ultraviolet (UV) radiation with a wavelength lower than 400 nm, and released light waves through electrical and physical changes. The wavelength is basically in the visible spectrum of the blue region between 400 and 450 nm. Because the observed light is the sum of reflected and emitted light under the illumination of an illumination light source containing a large amount of ultraviolet light, this light has a whiter color than white after being released from the paper containing the whitening agent. If the paper containing whitening agent is illuminated by ultraviolet light sources such as "black" light, you can often see this effect.

The paper printed on the base layer containing fluorescent whitening agent looks different in color, because it depends on whether the lighting source used to view the print contains ultraviolet light.

Early printing measurement standards (in addition to density standards) designated the lighting source as D50. Assume that the substrate is also measured with D50, regardless of the fluorescent whitening agent composition. In fact, under the actual observation conditions containing ultraviolet light, the colors seen are often not consistent, which cannot meet the requirements. These deviations pose a major challenge to people trying to measure and manage color consistency in different workflows.

New technology, new paper and new standards

New lighting sources, including light emitting diodes (LED), allow portable color measuring instruments to measure with their defined and controlled UV light components. In order to ensure consistency, the new light source and new substrate need new instruments and new standards to define and measure the UV light content, as well as the fluorescence of the fluorescent whitening agent contained in the substrate. It is very important to define and control the UV luminous component of the light source of the measuring equipment, so as to define a standard method to measure and manage the color of the printed matter containing the fluorescent whitening agent substrate.

Azeri has always been actively advocating and committed to the frontier field of design standards, and has always advocated the concept of "standard based printing". The factors driving the change include the improvement of technology, the continuous dissemination of information in different media, and the demand of printing suppliers and supply chain partners for improving efficiency, output and profits.

A series of new measurement conditions defined

As a part of ISO 13655-2009: spectral measurement and chromaticity calculation of printed images, the new measurement standard M series in measuring lighting conditions is stipulated by the International Organization for Standardization (ISO), and the lighting condition standards applicable to substrates containing different whitening agents are formulated.

The M series further improves the color management of substrates containing fluorescent whitening agents. Under different lighting sources, the color of materials containing fluorescent whitening agents will change, and M series came into being.

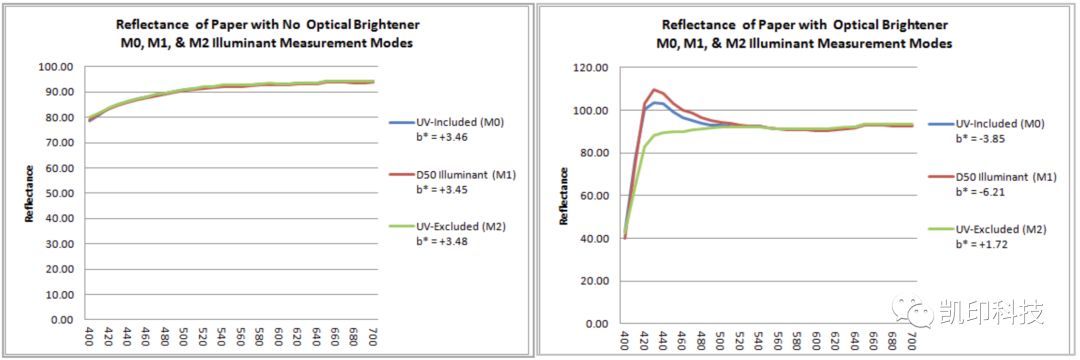

The above chart shows the effect of three different lighting conditions on the paper with and without fluorescent whitening agent. As shown in the figure, the change amount of the three lighting sources to the paper containing the whitening agent leads to the inability to match in most work processes and to meet the requirements of customers in the printing industry.

In order to reduce this change and provide an exchange method for measuring light sources, ISO13655 adopts a new representation method for measuring light source conditions, which defines four different measuring lighting conditions. This representation can also represent other measurement parameters such as polarized light. The M standard, as named, takes into account the conditions listed below.

Measurement condition M0

In the printing industry, the vast majority of spectrophotometers and densitometers use incandescent lamps, whose spectrum is close to the International Illumination Association (CIE) standard lighting source A, and the color temperature is 2856K ± 100K. This is the expected condition of M0. M0 is limited to the concept, that is, the measurement lighting conditions are not fully defined, and the ultraviolet light content of the light source is not determined. Because M0 also has a broader definition, including all instruments that do not apply to other M conditions. For example, it has been recognized that the color temperature of the lighting source in the product line of the instruments of Ashley and former GretagMacbeth is closely consistent with that of lighting source A.

The measurement lighting condition M0 does not define the content of ultraviolet light. Therefore, when the measured paper contains fluorescence and requires measurement data exchange between instruments, according to ISO13655, M0 is not recommended. The standard indicates that when there is no instrument that can meet M1, but the relative data is sufficient to meet process control or other data exchange applications, the instrument model similar to M0 can be used as an alternative. This clause can ensure that existing instruments will not cause problems immediately and continue to be used in the workflow. At present, M0 instruments are very popular.

Measuring lighting conditions M1

The measurement lighting condition M1 is defined to reduce the difference of measurement results between different instruments due to fluorescence, which is caused by the fluorescent brightener of the paper, or the fluorescence in the imaging pigment or proofing pigment. M1 (Part I) determines that the spectral power distribution of the sample illumination light source shall match the CIE illumination light source D50. M1 also specifies the second method to meet the requirements of M1. (Part II) This requirement is only applicable to the measurement of fluorescent whitening paper, not the measurement of ink or fluorescent toner. The historical reason is that it is difficult to have a real D50 lighting source in portable instruments. The second definition only requires the use of a compensatory method when adjusting the number of components (spectral region below 400 nm). This establishes a connection for the D50 lighting conditions defined in ISO 3664:2009 observation conditions. The second method must be closely related to the observation conditions in accordance with ISO 3664: 2009, so this method should be used with caution and testing is recommended to reach agreement.

Measuring lighting conditions M2

The ISO standard defines for the first time the exclusion UVs that should be included in the measurement tool (known UV-Cut, No UV, UV Filtered). M2 also provides tests that meet this standard. When the customer requires the instrument to be free of ultraviolet light, the instrument manufacturer now has a clear method to reach an agreement. We can measure the paper containing fluorescent whitening agent, and exchange more accurate and consistent color data. In the process of promoting XRGA, Aisele has ensured that all new products with UV Cut function meet this standard.

Measuring lighting conditions M3

M3 defines the polarization effect. In essence, M3 requires M2's UV limiting attribute, and adds the definition of polarization. Polarized light is used for some measuring instruments to eliminate or reduce specular reflection. Polarization standards are often met by selecting a polarizing function or adding a manufacturer specific polarizing filter. In the process of promoting XRGA (see the following content), Aisele guarantees that the instruments provided with M3 mode (polarized filter) can meet the new standard UV level.

Application of M0, M1, M2 and M3

• Theoretically, the use occasions of each measuring lighting condition are relatively clear

• M0 is applicable to the case where both the substrate and imaging pigment do not contain fluorescent whitening agent.

• M1, part I, is applicable to substrate or imaging pigment, or both contain fluorescent whitening agent

situation.

• M1, part II, is applicable to the substrate containing fluorescence. Fluorescence characteristics need to be collected, and it can be confirmed that the imaging pigment does not contain fluorescence. (If in doubt, it is recommended to consult the ink manufacturer.)

• M2 is used for paper fluorescence, but it is also hoped to eliminate the impact of data.

• M3 is used for special purposes, i.e. the first surface reflection should be reduced, including the use of polarized light.

In practical applications, the boundaries of these use cases are not clear. Today, with the help of M0 instrument, all standard printing conditions in the industry have been established. ISO is also examining this issue according to the continuous use of substrates and inks with fluorescent brighteners, but M0 has become the de facto standard measurement lighting condition in the printing industry.

Important factors to consider

To get the standard value, "print based on data" or meet the value provided by the customer, it is necessary to understand the source of the value. The density is less affected by the lighting source conditions, but it will cause density difference when measuring paper and non solid color. The response mode of different states (T, E) and/or the use of polarized light filters will vary greatly. When exchanging data, recording the measured lighting conditions (M0, M1, M2, M3) and chromaticity calculation methods (e.g. D50/2, D65/10) is as important as recording the density state.

Azeri is working with ISO to define a more sophisticated method for measuring data exchange using the Color Exchange Format (CxF). Our customers can believe that ASELI will provide a way to transfer from traditional instruments to XRGA instruments. This includes all measured lighting requirements and conditions specified in ISO13655. But before we started this activity, Ashley decided to help customers better manage the color data from our product family. This commitment has recently been partially implemented in XRGA and CxF. These technologies are designed to help reduce the differences between ASRIL instruments and standardize the file formats used for digital color data exchange. The existing products containing these technologies will help customers better measure the lighting conditions (M0-M3) with the new ISO measurement.

Azeri Printing Standard [XRGA]

Ashley and the former GretagMacbeth fully considered the historical situation of the two and provided tools to meet the needs of their customers and meet ISO standards. After the merger of Seli and GretagMacbeth, the new company realized the difference of measurement standards in the old product lines of the two companies. Both companies have traceable standards and processes. Ashley noticed that these differences are a problem for customers, especially those who use multiple measuring instruments or need data exchange.

XRGA is the calibration standard formulated by the new ASELI company for printing measuring instruments. This standard includes the new development of color technology and the change to meet the requirements of ISO-13655. The purpose is to ensure our optimal product portfolio, so that all customers, whether old or new, can enjoy high-quality data exchange in the workflow of different instruments.

Azeri Printing Standard [XRGA]:

Including the best classification method in measurement

Traceable to National Institute of Standards and Technology (NIST)

Compatible with existing ISO standard 13655

Improve the inter station protocol of existing instruments

Retain the agreement between the former Ashley and GretagMacbeth instruments

Provides a single standard for Ashley measuring instruments

The new printing measuring instruments are compatible with XRGA, and the existing instruments will also be compatible with XRGA when returned to ASELI for annual calibration.

CxF3

CxF3 specifies an XML (Extensible Markup Language) based on the color specification mechanism, which is comprehensive and flexible, and can be applied to various industries where the exchange of color and appearance data is crucial. CxF takes advantage of the openness and wide acceptance of XML, so it can be seamlessly integrated in any workflow. By using XML, CxF provides self identifying color data and establishes a flexible communication mechanism. CxF can seamlessly integrate data obtained by other color communication methods, including ICC color profile, density, CIE Lab, XYZ, RGB, CMYK, PANTONE, RAL, NCS, Toyo, HKS, etc. CxF is currently a theme in the development process of ISO standards, covering a comprehensive topic: ISO17972 Flat Image Technology Color Technology Exchange Format (CxF/X)

conclusion

Aiseli will continue to support the formulation and revision of new industry standards. To this end, we help customers and the entire industry to improve quality and promote prosperity to new heights. We are honored to work with outstanding talents in many work processes and look forward to continuing to provide support in the printing industry with the best measurement tools in the world.

Glossary of professional terms

CGATS: Graphic Arts Technologies Standards

CxF: Color Exchange Format

D50: Daylight 5000K Daylight 5000 Kelvin

ISO: International Organization Standards

LED: Light emitting diodes

M: Measurement Mode

Nm: Nanometers

UV: Ultraviolet

XML: eXtensible Markup Language

XRGA: X-Rite Graphic Arts Standards

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Shenzhen is a city of innovation and entrepreneurship. There are many small and medium-sized enterprises with high growth, often with huge potential and irreplaceable position in their respective fields. Shenzhen Satellite TV Finance Channel is the only authoritative local financial media in Shenzhen. Through Shenzhen Enterprise Power, it aims to tell the story of Shenzhen enterprises and show Shenzhen's innovative vitality.

Kaiyin Technology | Strength won the national high-tech enterprise recognition

At the beginning of the spring of 2020, Kaiyin Technology has received good news. In accordance with the relevant provisions of the Measures for the Administration of the Recognition of High tech Enterprises and the Guidelines for the Administration of the Recognition of High tech Enterprises issued by the State Administration of Taxation, Shenzhen Kaiyin Science and Technology Co., Ltd. was successfully recognized as a national high-tech enterprise in December 2019 through layer upon layer review in the selection of national high-tech enterprises.

"Color Data Lab" of Aisele Kaiyin was established

On July 22, 2019, Shenzhen Kaiyin Technology Co., Ltd., located on the 40th floor of Changping Business Building, Futian District, Shenzhen Bay, was authorized by Mr. Elton Pan, the general manager of Aiselei Greater China, on behalf of Aiselei, to Mr. Chen Shaozhong, the technical director of Shenzhen Kaiyin Technology Co., Ltd. So far, the long-awaited "color data laboratory" of Aisele Kaiyin was officially established. It has also become the first "color data laboratory" co established by Aiseli in Shenzhen. This will certainly provide a good interactive color management training, communication and experimental platform for printing and packaging enterprises.

Application Practice of Ashley eXact Measuring Instrument - Best Match!

Every printing work order, we have to face a problem, how to keep up with the "goal". The printing buyer gives you a target data, chromaticity/density/color difference... or a target sample... or an international standard Gracol 2006/Gracol 2013, Fogra 39/Fogra 51

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time