Expert Explanation - A Comprehensive Analysis of How to Choose and Effectively Use CTP

Release Time: 2022-12-02 17:32:45.820

CTP is more than just a plate making machine; it actively improves printing quality and efficiency. For example, it avoids the problems of dot loss, deformation, and expansion, reduces the loss of color and layers, shortens the time required for ink color adjustment, register adjustment, and ink-water balance during printing, thus greatly improving printing quality and production efficiency.

From the perspective of color management, it is necessary to control dot gain, ink presetting (CIP3/4), ink density, chromaticity (Lab), and overprinting. These quality factors are closely related to the selection and use of CTP equipment. Therefore, we must not only choose the right CTP but also use it well.

How to choose the right CTP?

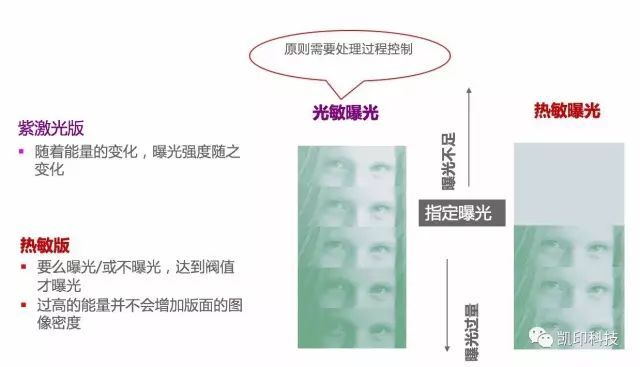

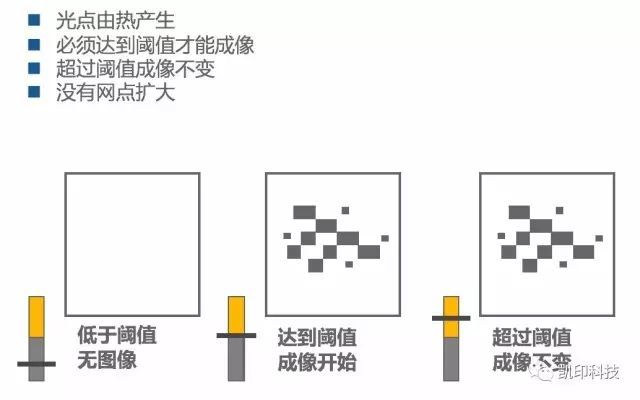

The first step in choosing a CTP: photosensitive or thermal?

In choosing a CTP, we must first understand the technologies currently available on the market. The technologies are divided into thermal CTP and photosensitive CTP. In terms of market share, thermal CTP has undoubtedly become the mainstream and is unstoppable, with over 95% of printing plants choosing thermal CTP. The reason is obvious: Most importantly, thermal CTP offers stable exposure control, meaning stable dots, which is a fundamental condition for good color management.

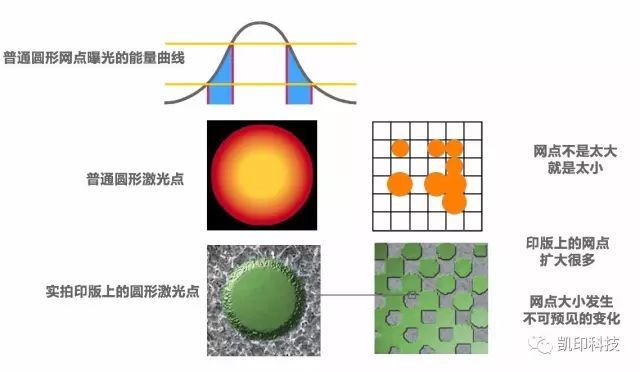

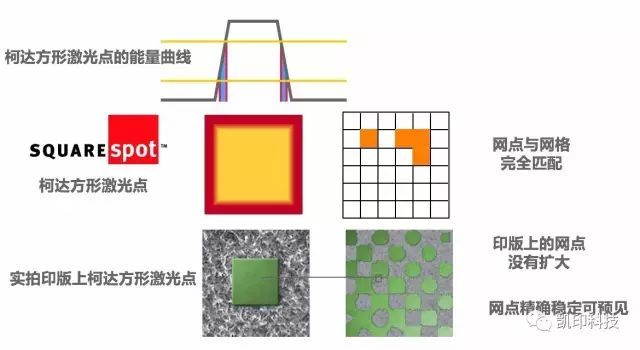

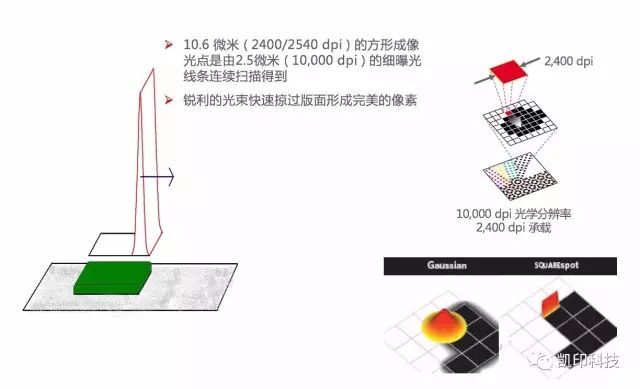

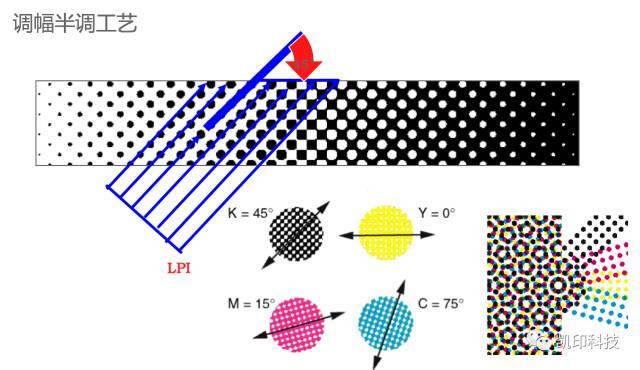

The second step in choosing a CTP: square dots or round dots?

Obviously, square dots are superior in terms of dot sharpness;

They can achieve 10-micron frequency modulation screening, a unique capability of square laser dot technology. This is why high-precision printing, such as 3D and high-definition printing, generally uses square dots.

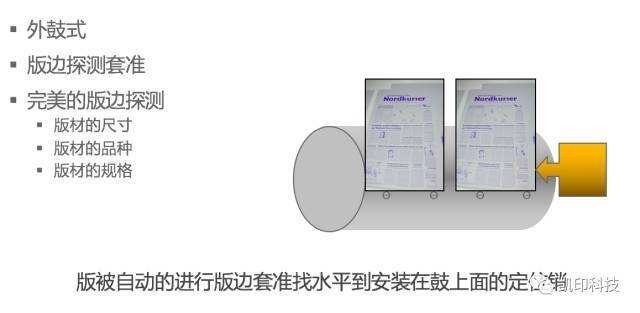

The third step in choosing a CTP: plate edge detection function - maintaining accurate register

The fourth step in choosing a CTP: automatic focusing function - compatibility with more plate materials/handling of anomalies

How to adapt to the uneven quality of plate materials from different brands on the market? Even if there is a little dust or anomaly on the surface of the printing plate, with the automatic focusing function, the CTP will easily cope and ensure perfect exposure under various conditions.

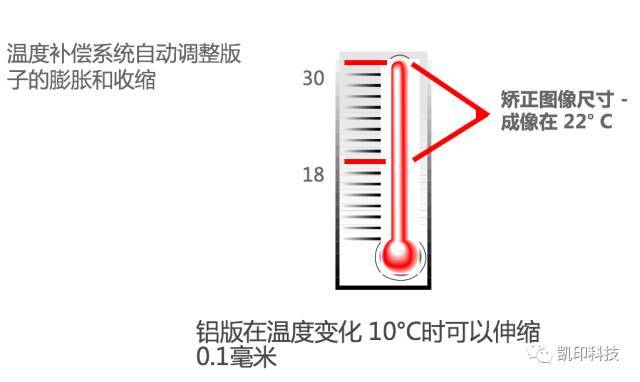

The fifth step in choosing a CTP: temperature compensation function - ensuring accurate register for plate remakes

An aluminum plate can expand or contract by 0.1 mm when the temperature changes by 10°C. So, how to ensure register for plates made at different times? The temperature compensation function can compensate for these differences.

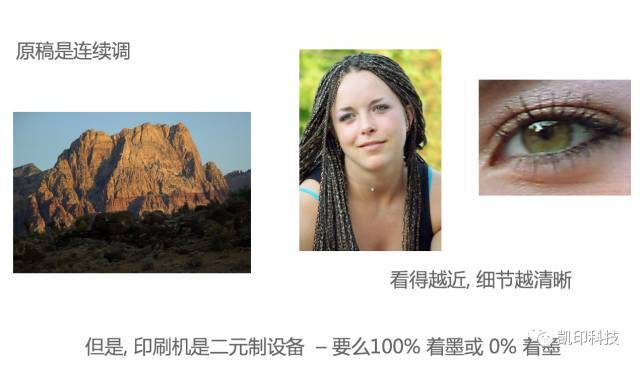

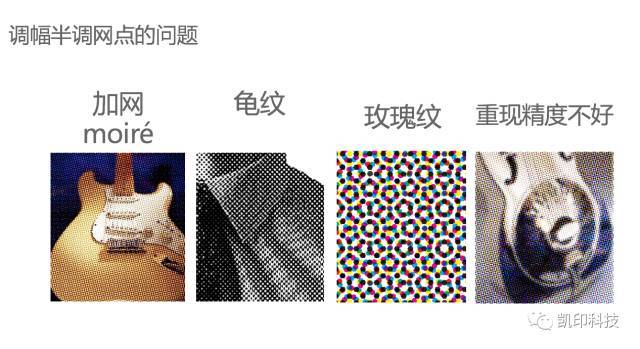

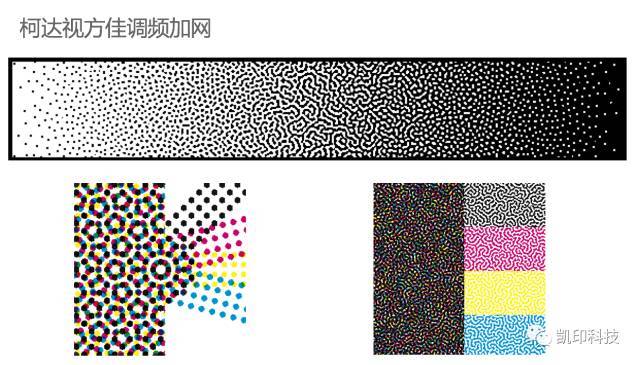

The sixth step in choosing a CTP: FM screening - higher precision printing

When the following problems occur during production;

Or when higher precision printing is required, such as 3D printing and high-definition printing. FM screening will be a better solution.

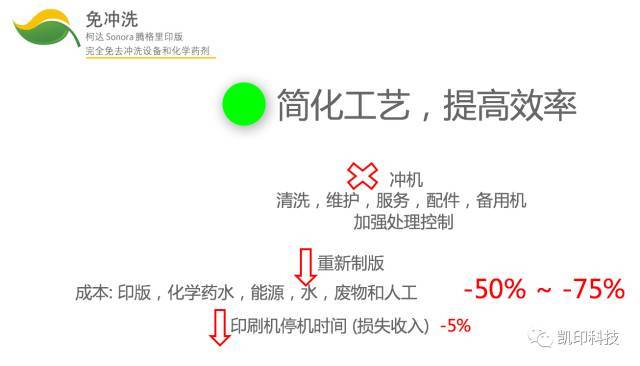

The seventh step in choosing a CTP: waterless environmentally friendly CTP plates - easily addressing environmental issues

How to use CTP well? The first step in using CTP well

Standardization of CTP and plate processor status

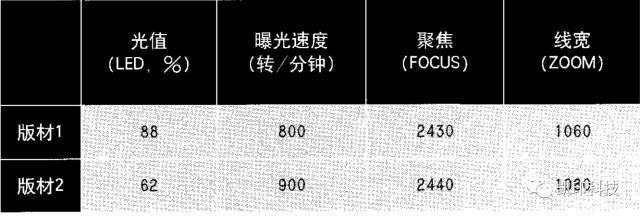

- Set exposure according to plate material characteristics

- Accurately set the plate processing speed and developer replenishment amount

- Chemical solution circulation settings

- Developer temperature and PH value within the standard range

- Adjust brush pressure

- Regularly check and replace filter cartridges

- Check plate thickness/flatness

- Plate room temperature and humidity (temperature: 20-25°C/humidity: 50%-60%)

- Required measuring instrument: water tank tester, Hanna four-in-one recommended

The second step in using CTP well: correct use of the plate control strip

The control strip is a commonly used tool for controlling plate quality. Operators must understand the function of each control module on the control strip, correctly set the parameters of the CTP equipment, and understand the equipment status.

The third step in using CTP well: dot gain control - plate

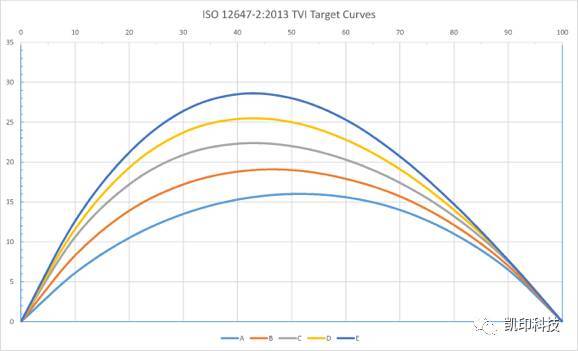

- Dot gain on the CTP plate should not exceed 1%; otherwise, a linearization curve should be created to control the dot gain caused by the CTP itself within 1%;

- Plate curve correction tool required

Kodak Harmony

- Required measuring instrument: X-Rite icpateII plate tester

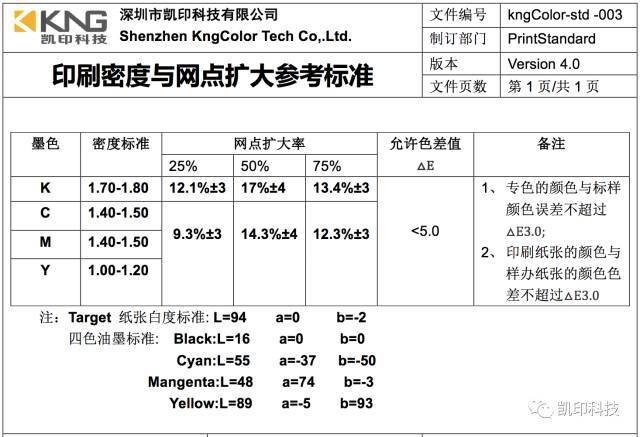

The fourth step in using CTP well: dot gain control - printing

During printing, the printing press will cause a certain deformation of the rubber blanket during printing, plus the tension of the ink and the absorption of the paper, resulting in a change in the dot area, and the dot edges expand outwards, forming dot gain. The status and materials of each printing press are different, so the dot gain is also different. When the measured dot gain of the printed product still has a certain gap with the printing standard, the dot gain should be compensated again through the plate curve correction tool.

- Standard dot gain value:

- Plate curve correction tool required

Kodak Harmony

- Required measuring instrument: X-Rite eXact spectrophotometer

The fifth step in using CTP well: ink presetting - CIP3/4

The biggest advancement of CTP is the digitization of printing information;

1. The plate transmits image and text information and dots from prepress to the printing press;

2. The required ink amount and ink position information are transmitted to the printing press via the CIP3/4 file. At this time, the setting of the CIP3/4 output in prepress is very important;

3. The printing job information is continuously collected during the file creation, typesetting, and plate making process, and finally transmitted to the printing press. The entire process is transmitted via the JDF format;

-END-

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Kaiyin Technology - Awarded "Specialized and New Enterprise"

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen municipal preliminary examination, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements. It marks another significant step forward for Kaiyin Technology in technological innovation and development in its specialized field.

MeasureColor and eXact AutoScan help you achieve exceptional print quality.

Achieving stable print quality hinges on your ability to control dot gain—a critical yet often overlooked variable. Dot gain significantly impacts color accuracy, image sharpness, and overall visual performance, particularly in packaging printing and workflows involving expanded color gamuts. With MeasureColor, printers can access advanced tools that enable them to effortlessly monitor, manage, and optimize dot gain in real time—eliminating the need for subjective guesswork.

On the journey toward higher precision, greater efficiency, and more sustainable development in the printing industry, the plate-making stage has always served as a crucial link—connecting the past with the future. As numerous printing companies choose among the dazzling array of CTP (Computer-to-Plate) equipment available, one well-known name—Kodak—often finds itself at the center of attention with its CTP solutions.

In manufacturing, even the slightest difference in color can often be the dividing line between high-quality and substandard products. Whether it’s apparel, building materials, cosmetics, or durable consumer goods, consistently accurate colors are not only a pursuit of product aesthetics—they also serve as the cornerstone of brand commitment and customer trust. Achieving this goal is inseparable from powerful color measurement tools—high-performance spectrophotometers.

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time