G7 Certification | Standardized Print Color Management

Release Time: 2023-11-30 00:00:00.000

Foreword

Color is at the core of printing and reproduction. In today's printing industry, which is facing meager profits and homogenization, printing companies are increasingly focusing on improving print color management methods. Currently, the growing popularity of printing company certifications is a beneficial exploration by companies to enhance color reproduction quality. Among various certification systems, GRACoL's is the most widely recognized G7 Certification System 。

As of now, hundreds of companies in mainland China have obtained G7 Accredited Company qualification, and the application of printing standardization has begun to penetrate small and medium-sized enterprises. These certified companies are mainly offset printing and prepress companies, simultaneously achieving G7 Targeted or G7 ColorSpace levels. The G7 Accredited Company qualification is valid for one year, and companies must re-certify annually. Therefore, obtaining G7 certification is not the end Achieving digitized, standardized, and normalized production, and maintaining a long-term, stable, and repeatable printing state is the ultimate goal of G7 certification 。

G7 Process and G7 Certification Introduction

GRACoL is the Graphics Communications Association of America, a branch committee under IDEAlliance responsible for research in offset printing technology. G7 is a new set of standardized calibration, detection, and control methods for printing created by this organization. So, strictly speaking, G7 is a process control method. This method focuses on controlling neutral gray, emphasizing the effect of visual gray balance. Here, G stands for grayscale calibration, and 7 represents the seven basic colors defined in the ISO 12647-2 printing standard: cyan, magenta, yellow, black, red, green, and blue. This method can be applied not only to the calibration of printing equipment but also to other CMYK output devices, such as inkjet printers, laser printers, etc. Moreover, when using the G7 method for general calibration, there are no specific requirements for paper, ink, screen ruling, printing, or output systems.

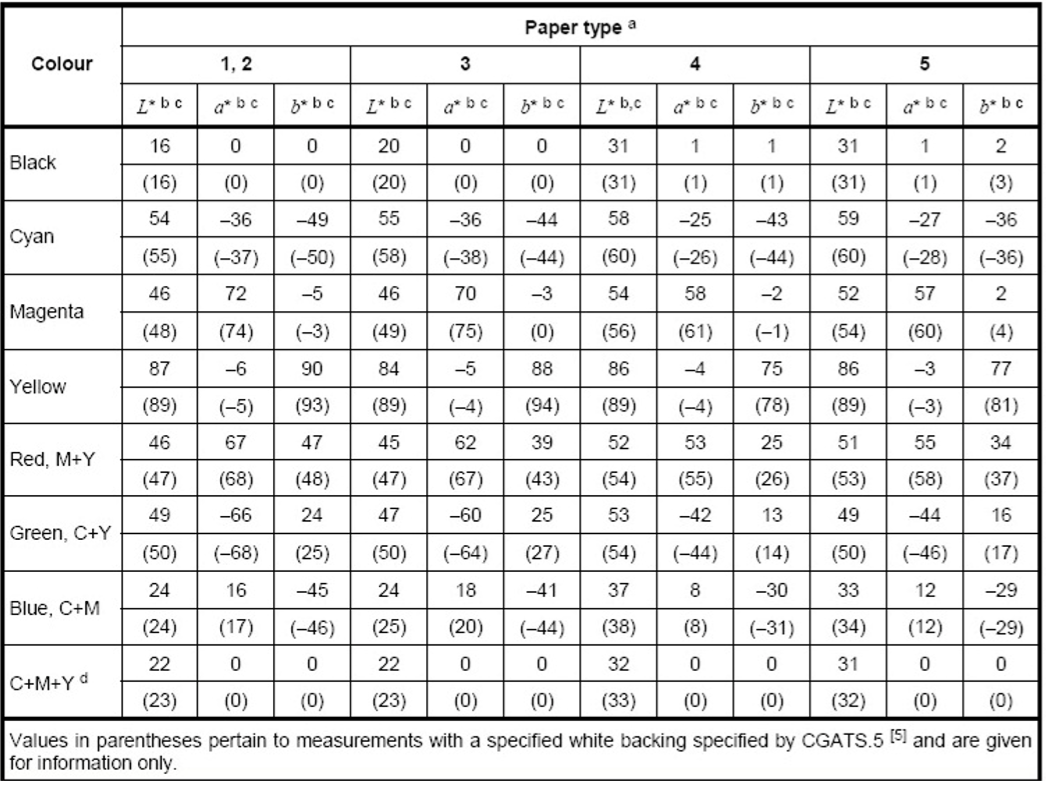

G7 certification refers to calibrating a printing system using the G7 correction method. Provided that the performance and tolerances of the paper and ink used meet ISO 12647-2 requirements, the entire printing process will eventually satisfy all ISO 12647-2 standard requirements, thereby obtaining a "G7 Certified" certificate. Information about certified printing companies will be included in the G7 database for inquiry, providing printing companies with broader customer trust and sources. Based on the client's existing resources and conditions, G7 certification can be divided into different levels.

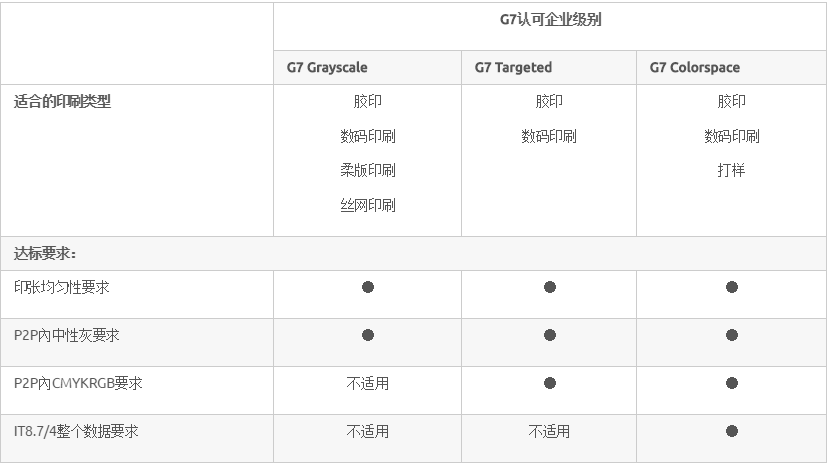

G7 Certification Levels

I. G7 Grayscale Compliance Requirements

G7 Grayscale is the lowest level in the G7 Accredited Company program. Offset, digital, flexographic, and screen printing companies can all achieve this level, provided they meet the neutral gray requirements. During certification testing, the neutral gray requirements of both left and right P2P targets will be measured. During certification testing, both left and right P2P targets will be measured to check if neutral gray meets the standards 。

II. G7 Targeted Compliance Requirements (ISO or non-ISO standard paper can be used)

Offset and digital printing companies can both achieve the G7 Targeted level. In addition to meeting the neutral gray requirements of G7 Grayscale, CMYK and RGB must also meet the standards. It is required to use CMYK inks that meet ISO 12647 requirements. For paper, ISO or non-ISO standard paper can be selected. If a company uses non-ISO standard paper, it can apply the concept of [substrate-corrected aims] to recalculate the print targets. If the print sheet meets the requirements, the company can obtain the "G7 Targeted-Relative" qualification. Companies can also choose to use ISO standard paper for certification; if the print sheet meets the standards, the company can obtain the "G7 Targeted" qualification.

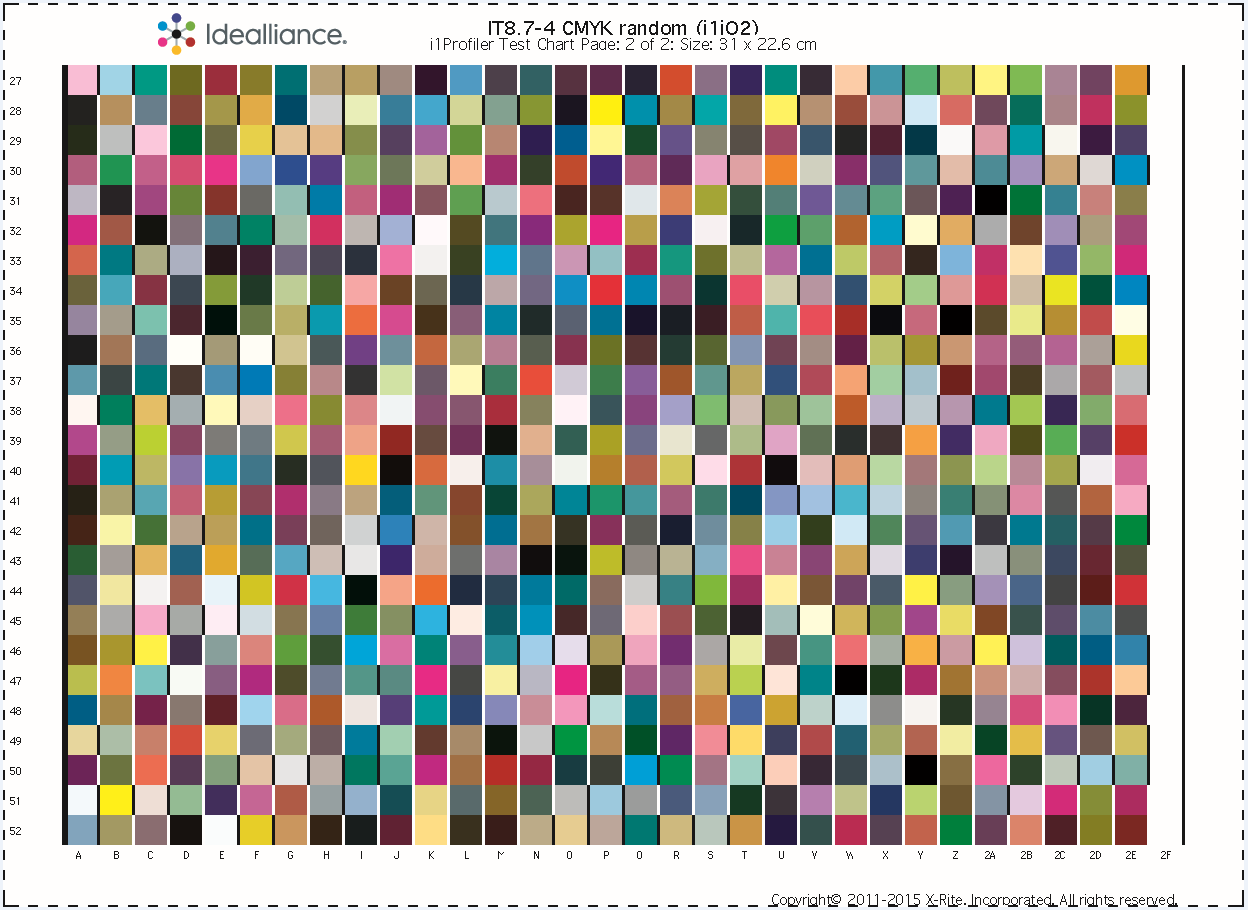

III. G7 Colorspace Compliance Requirements (ISO standard paper must be used)

G7 Colorspace is the most challenging level in the G7 Accredited Company program, suitable for offset printing, digital printing, or prepress (e.g., platemaking or providing digital proofing services) companies to achieve. To obtain this level, ISO standard paper must be used; in addition to meeting the G7 Targeted requirements, the entire IT8.7/4 or TC1617 data must also meet the compliance requirements.

G7 Certification Advantages

For Printing Companies

-

Applying G7's calibration method can improve the tonal gradation of printed materials, enhance the neutral gray performance, and better neutral gray performance fundamentally aligns with the essence of printing: "color reproduction."

-

The implementation of G7 process brings higher production efficiency and significant savings in production preparation time

-

Product production takes a reproducible and repeatable path

-

The optimal density control and neutral gray control methods used in G7 certification provide means and ideas for the production process control of printed materials, leading to reproducible and repeatable product production

-

Improves internal communication among various departments of the company, increasing trust between different production stages

-

Printing companies implementing standardized processes can achieve higher customer satisfaction

-

Enhances corporate reputation, providing printing companies with broader customer trust and sources

For Print Buyers

-

Provides them with better predictability for their products

-

Improves communication and exchange between product design and printing, making buyers trust their suppliers more

-

Ensures good product quality consistency for buyers' different products, multiple print runs of the same product, and when using products from different suppliers

Certification Application

Printing companies can apply for G7 certification to the local G7 certification body, or they can directly contact relevant G7 experts to apply. Kaiyin Technology Senior G7 Expert—James chen. 陈绍忠

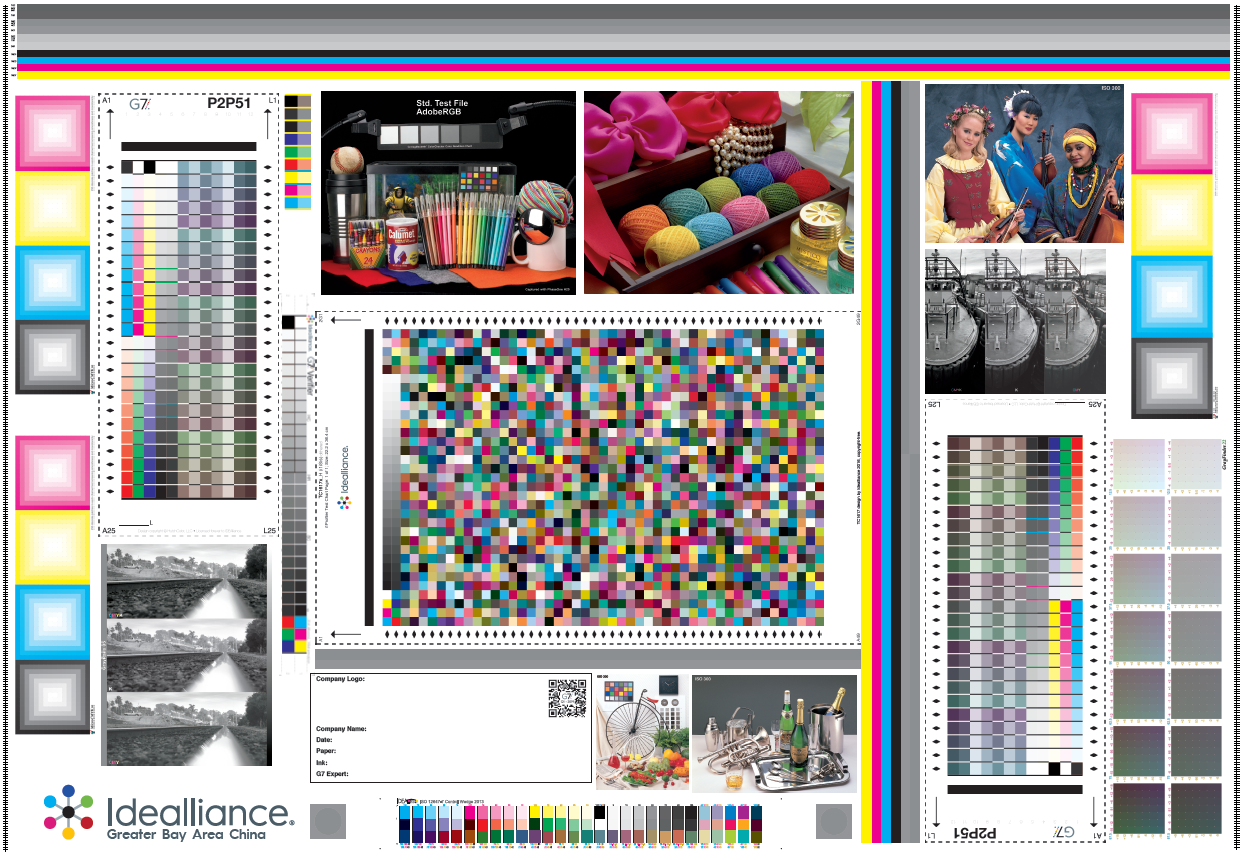

Before all companies proceed with G7 certification, they must first apply to Hong Kong APTEC for a P2P color chart with a QR Code. The relevant G7 expert must provide the customer with the APTEC-designated press test sheet. It is recommended that G7 accredited companies use full-sheet test prints, i.e., folio or quarto size, covering at least 70% of the printing press area.

Before the project preparation

Although G7 itself is not a true ISO standard, G7 certification requires that the materials, tools, measurement conditions and methods, and observation environment involved in the certification process must meet the requirements of relevant ISO standards. Therefore, printing companies must complete the necessary preparatory work before initiating the certification process.

-

Ink: The ink used must meet the requirements of the corresponding ISO 2846 standard, which clearly specifies the requirements for four-color printing inks (except that the G7 GrayScale level is not required; it is recommended to use qualified inks).

-

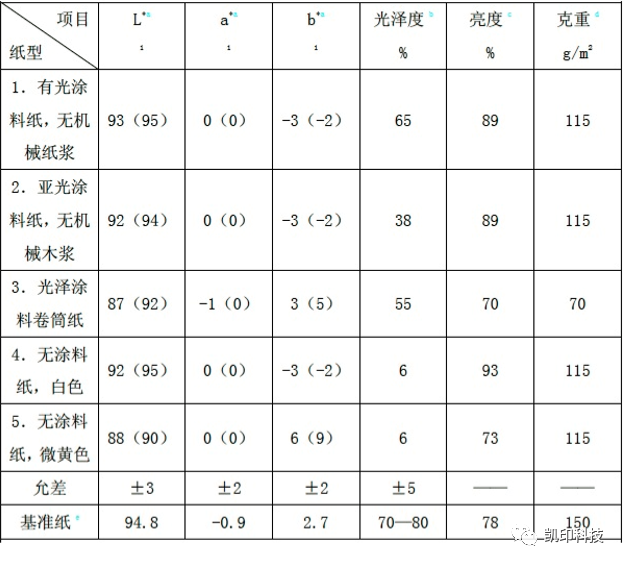

Paper: G7 Colorspace: The paper's white point LAB value must have a color difference of less than or equal to 3 compared to the white point required by GRACoL 1, SWOP 3, and SWOP 5; G7 Targeted: The paper's white point LAB value must have a color difference of less than or equal to 5 compared to the white point required by GRACoL 1, SWOP 3, and SWOP 5. If the LAB value difference is greater than 5, the applicant should apply using the [paper white compensation adjustment] method.

-

First Machine Trial Print: Use the current combination of printing/ink/substrate to test the "original" neutral gray printing density curve, check ink uniformity, and whether the color density is consistent from left to right and top to bottom.

CMYK Four-Color Lab Standard

Overprint RGB Lab Target

-

Measuring Tools: The implementation of G7 certification requires specialized measuring instruments and software to obtain the necessary test data. All color measurements must comply with ISO 13655. Equipment includes: Track scanning equipment (eXactAutoScan reduces the time for master color adjustment, allowing for faster and more even color printing), spectrophotometer (X-Rite eXact, X-Rite I1IO, X-Rite I1Isis), and plate measuring instrument (such as X-Rite ICPlate2 XT, and the calibration report is not expired).

-

Equipment Calibration: Before conducting the formal certification test, printing companies must conduct necessary inspections and calibrations of CTP and printing equipment to ensure stable and correct production.

-

CTP Calibration: According to the instructions provided by the CTP manufacturer, adjust the CTP focal length and exposure to ensure accurate reproduction of halftone information; check the operation status of the plate processor, control the pH value of the developer, etc., to ensure the stable and controllable physical and chemical state of the CTP plate-making system.

-

Printing Machine Calibration: The printing machine (including consumables) should be maintained in a stable state, and its relevant physical and chemical parameters should be checked to ensure they meet the requirements. To better understand and control the printing machine's status, necessary printing machine tests should be conducted. These tests include: dry density pressure test, mechanical ghosting, bar lifting, and printing registration. Adjust the printing machine based on the test results (if necessary, consult a printing technician for debugging) until the printing machine is in optimal working condition.

-

Observation Environment: G7 certification requires that the printing machine viewing conditions meet ISO standards. ISO 3664 provides standard viewing conditions for the printing industry, requiring the printing light source to have a color temperature of 5000K and a color rendering index (CRI) of no less than 90.

Project Implementation 施

After the printing company confirms that the necessary preparations for certification are complete, the G7 certification process can be started. The entire certification process must be guided and audited on-site by a G7 certified expert. The G7 expert will conduct on-site training for the company's relevant personnel, covering G7 certification knowledge, G7 correction methods, and the use of certification tools, enabling printing company employees to understand the entire certification process, key aspects, and basic G7 correction methods.

G7 Certification Knowledge Training

The G7 expert will conduct on-site training for the company's relevant personnel, covering G7 certification knowledge, G7 correction methods, and the use of certification tools, enabling printing company employees to understand the entire certification process, key aspects, and basic G7 correction methods.

First Round of Linear Printing

In the original state where the CTP does not load any curves, linearly output the test plate dedicated to G7 certification, record the page halftone information, and better control the plate-making process in the future;

Print this test plate on the machine. The printing status at this time must be a stable state that has been adjusted to meet the requirements. Use a spectral densitometer to find the optimal solid density of the printing machine. After the printing is stable, sample several printed samples according to the sampling rules.

CTP Compensation Correction

By measuring specific elements on the sampled printed samples, obtain the necessary information, use Curve software to process and obtain the CMYK correction results, assign new target values to the RIP, and complete the CTP correction.

Second Round of Certification Printing

The CTP system loads the correction curve created above and prints with the optimal density from the first round. To ensure that the printing status is as consistent as possible, both rounds of printing are completed on the same day, on the same machine, and by the same crew, keeping all printing machine settings unchanged. Sample according to the rules under stable printing conditions, and submit the sampled sheets to the on-site G7 certification expert.

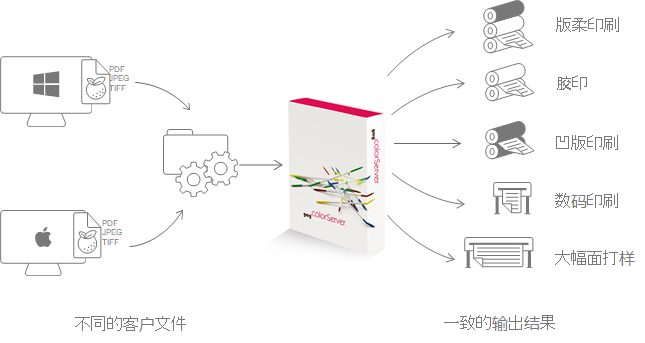

How to Make G7 Production Easier—File Color Standardization Conversion

Using GMG ColorServer, your data can be printed immediately and quickly achieve the G7 target. GMG's MX technology (integrated into GMG ColorServer) produces the highest quality color space conversions. This technology preserves the black channel, stabilizes color, and achieves unparalleled shadow clarity to deliver consistent, noticeably superior results unmatched by any other solution on the market.

GMG color conversion is a four-dimensional conversion directly from RGB to CMYK or CMYK to CMYK, maintaining the independence of the black channel…

(Using GMG CMYK conversion characteristic files for color conversion)

(Using ordinary ICC conversion characteristic files for color conversion)

Audit Certification 证

The G7 certification expert will make an on-site judgment based on the printed samples. If the on-site evaluation is passed, the G7 expert will submit the two sets of sampled prints to the certification agency for final evaluation, which takes about 14 working days. If passed, the printing company will receive a G7 certification certificate and logo from the G7 certification agency, and the company information will be included in the G7 certification database on the website for query.

Maintenance of the G7 Certification System

This is the most important part. The G7 certification is valid for one year, and to maintain it, an annual review is required. Therefore, obtaining G7 certification is not the end goal; the ultimate objective is to achieve data-driven, standardized, and normalized production to maintain long-term, stable, and repeatable printing conditions.

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Kaiyin Technology - Awarded "Specialized and New Enterprise"

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen municipal preliminary examination, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements. It marks another significant step forward for Kaiyin Technology in technological innovation and development in its specialized field.

MeasureColor and eXact AutoScan help you achieve exceptional print quality.

Achieving stable print quality hinges on your ability to control dot gain—a critical yet often overlooked variable. Dot gain significantly impacts color accuracy, image sharpness, and overall visual performance, particularly in packaging printing and workflows involving expanded color gamuts. With MeasureColor, printers can access advanced tools that enable them to effortlessly monitor, manage, and optimize dot gain in real time—eliminating the need for subjective guesswork.

On the journey toward higher precision, greater efficiency, and more sustainable development in the printing industry, the plate-making stage has always served as a crucial link—connecting the past with the future. As numerous printing companies choose among the dazzling array of CTP (Computer-to-Plate) equipment available, one well-known name—Kodak—often finds itself at the center of attention with its CTP solutions.

In manufacturing, even the slightest difference in color can often be the dividing line between high-quality and substandard products. Whether it’s apparel, building materials, cosmetics, or durable consumer goods, consistently accurate colors are not only a pursuit of product aesthetics—they also serve as the cornerstone of brand commitment and customer trust. Achieving this goal is inseparable from powerful color measurement tools—high-performance spectrophotometers.

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time