Color Management Technology Sharing | What are the different types of spectrophotometers

Release Time: 2024-06-03 09:00:00.000

A spectrophotometer is an instrument that measures color by shining a beam of light and capturing the amount of light reflected or transmitted to quantify color. Spectrophotometers can provide color data for virtually any sample, including liquid, plastic, paper, metal, fabric, and paint samples. Spectrophotometers are used in every industry that requires accurate color. From packaging to textiles to beverages and plastic parts, these devices help ensure that the color produced matches the color initially specified.

How do spectrophotometers measure color?

Using a light source, a spectrophotometer can accurately detect color reflectance or transmittance for quantitative analysis. Each physical sample has its own reflectance (amount of light reflected) and transmittance (light absorption). The spectrophotometer measures the reflected or transmitted light of the sample to capture its fingerprint and determine the amount of light reflected or transmitted from different parts of the visible spectrum.

What is the difference between reflectance and transmission spectrophotometers?

Solid samples can absorb or reflect light. To measure solid objects, a reflectance spectrophotometer shines a beam of light onto the surface, and a detector measures the intensity of light reflected back from specific wavelengths of the visible spectrum. This is called reflectance measurement, typically achieved within the instrument using a rotating filter wheel or diffraction grating with specially designed colors. The resulting measurement is the reflectance curve of the sample, with wavelengths ranging from 400 to 700 nanometers.

For example, a sample that absorbs light across all visible wavelengths and does not transmit any visible wavelengths appears black. If all visible wavelengths are transmitted (the sample does not absorb any), the sample will appear white. If the sample absorbs red light (approximately 700 nm), it will appear green, as green is the complementary color of red. Translucent samples, such as plastic films and clear liquid sample solutions, allow light to pass through. To measure translucent samples, a transmission spectrophotometer transmits light through the sample and measures how much light passes through the visible spectrum.

What is a UV spectrophotometer?

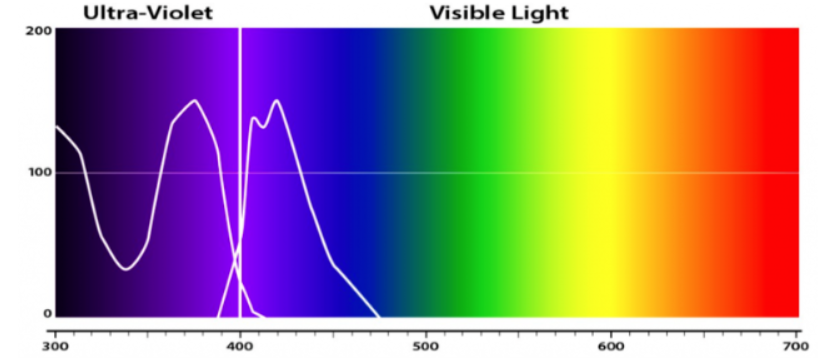

In addition to measuring the transmittance or reflectance of visible light, UV-Vis spectrophotometers with calibrated UV light can also measure the component wavelengths of the ultraviolet range (185-400 nm) and visible light range (400-700 nm) of the electromagnetic radiation spectrum. Spectrophotometers quantify the amount of ultraviolet and visible light absorbed by the sample concentration, which can assess the color consistency of products containing OBAs. These devices provide calibrated UV light to measure and quantify this effect.

What is a spectral reflectance curve?

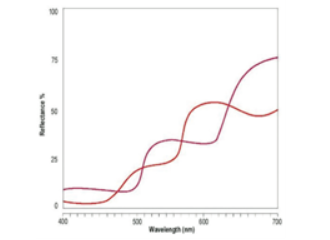

Using a spectrophotometer, you can measure an object to see how much light is reflected at each point in the visible spectrum. Think of this color measurement as a unique fingerprint for that sample. The resulting reflectance data is the "fingerprint" of that color, which can be used to create a reflectance curve. The reflectance curves of two samples can be compared to see if they match and identify metamerism issues.

What is metamerism?

Metamerism is the phenomenon where shades appear the same under a single specified lighting condition but have different fingerprints.

This figure shows the reflectance curves of two reds. Both curves strongly absorb blue, both moderately absorb green, and both are strong reflectors of red. Note how the curves intertwine. Whenever the curves of two physical samples cross at least three times, they are a metameric pair. Metamerism is apparent when objects are metameric pairs. Although they sometimes appear to be the same color, they will not match under all lighting conditions.

What are the different types of spectrophotometers?

If all samples were flat, opaque, or the same thickness, one instrument would work for all industries. However, samples can be curved, transparent, metallic, textured, or more. When choosing a spectrophotometer, it is important to find one that meets your needs based on what you are measuring.

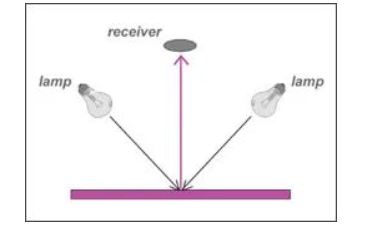

As one of the most common types of spectrophotometers, this measurement geometry emits light at 45 degrees to the sample surface and measures the light reflected at a fixed angle to the sample, namely 0 degrees. This type of measurement excludes gloss, to most closely replicate how the human eye sees color, and is commonly used to measure color on flat, smooth, or matte surfaces.

0:45/45:0 Spectrophotometer

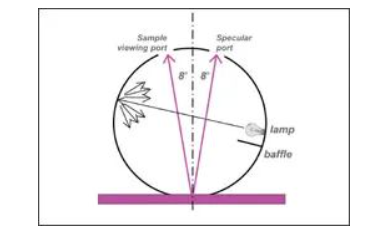

Integrating sphere instruments capture light reflected from all angles of the sample. This type of measurement can include or exclude the surface appearance of the sample. These devices are commonly used to measure color applied to textured surfaces (such as textiles, carpets, and plastics) as well as glossy or specular surfaces (including metallic inks and foil printing).

Integrating Sphere Spectrophotometer

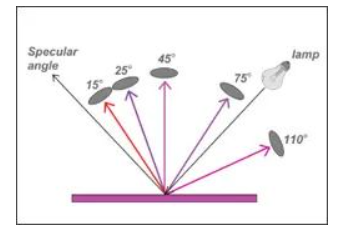

Multi-angle instruments can view the color of a sample as if it were rotating back and forth, much like you would twist a sample to view the color at different angles. Today's multi-angle instruments are commonly used for specialty coating pigments and special effect colors with additives, such as nail polish and automotive coatings.

Multi-angle Spectrophotometer

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Kaiyin Technology - Awarded "Specialized and New Enterprise"

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen municipal preliminary examination, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements. It marks another significant step forward for Kaiyin Technology in technological innovation and development in its specialized field.

MeasureColor and eXact AutoScan help you achieve exceptional print quality.

Achieving stable print quality hinges on your ability to control dot gain—a critical yet often overlooked variable. Dot gain significantly impacts color accuracy, image sharpness, and overall visual performance, particularly in packaging printing and workflows involving expanded color gamuts. With MeasureColor, printers can access advanced tools that enable them to effortlessly monitor, manage, and optimize dot gain in real time—eliminating the need for subjective guesswork.

On the journey toward higher precision, greater efficiency, and more sustainable development in the printing industry, the plate-making stage has always served as a crucial link—connecting the past with the future. As numerous printing companies choose among the dazzling array of CTP (Computer-to-Plate) equipment available, one well-known name—Kodak—often finds itself at the center of attention with its CTP solutions.

In manufacturing, even the slightest difference in color can often be the dividing line between high-quality and substandard products. Whether it’s apparel, building materials, cosmetics, or durable consumer goods, consistently accurate colors are not only a pursuit of product aesthetics—they also serve as the cornerstone of brand commitment and customer trust. Achieving this goal is inseparable from powerful color measurement tools—high-performance spectrophotometers.

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time