Color Management Technology Sharing | What is a spectrophotometer/spectrometer? (Part 1)

Release Time: 2024-06-05 09:00:00.000

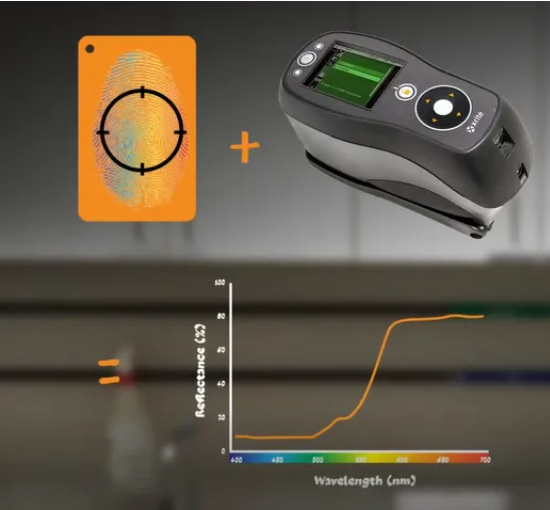

A spectrophotometer is a color measurement device used to capture and evaluate color. As part of a color control program, especially in global and distributed environments where components are manufactured in different locations and assembled together as a whole, brand owners, designers, suppliers, and manufacturers use spectrophotometers to specify and communicate color, and manufacturers use them to monitor color accuracy throughout the production process.

Each physical sample has its own reflectance, or the amount of light reflected, and transmittance, or the amount of light absorbed. A reflectance spectrophotometer emits a beam of light and measures the amount of light reflected from different wavelengths of the visible spectrum, while a transmittance spectrophotometer measures the amount of light that passes through the sample. Spectrophotometers can measure and quantitatively analyze almost anything, including liquids, plastics, paper, metals, fabrics, and painted samples to verify color consistency from conception to delivery.

Spectrophotometer Types

There are three main types of spectrophotometers. Your choice depends on the application, required functionality, and portability. Spectrophotometers come in a variety of sizes, from portable devices to large benchtop instruments.

0º/45º (or 45º/0º) Spectrophotometer

This instrument is the most common spectrophotometer, measuring the wavelengths of light reflected at a fixed angle to the sample, typically 45°. This type of spectrophotometer is compact and can exclude gloss to most closely replicate how the human eye sees color. It is commonly used to measure color on smooth or matte surfaces.

The first number refers to the illumination angle, and the second number refers to the detection angle. With a 45:0 spectrophotometer, the light source illuminates at a 45° angle to the normal of the sample, and the detector receives the reflected light at a 0° angle, or perpendicular to the object surface.

Sphere Spectrophotometer

Sphere spectrophotometers measure light reflected at all angles to calculate color measurements that closely approximate those seen by the human eye. They are commonly used to measure the color of textured surfaces (such as textiles, carpets, and plastics) as well as shiny or specular surfaces (including metallic inks, foil printing, and other high-gloss surfaces). Some sphere spectrophotometers that support UV can assess UV light in the wavelength (185 - 400 nm) UV range.

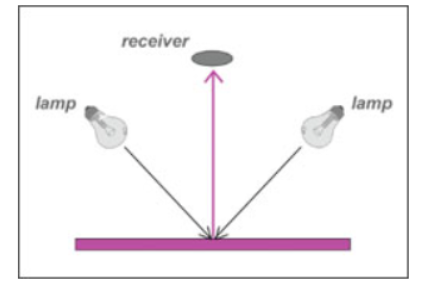

With a sphere spectrophotometer, the object being measured is illuminated diffusely, or from all directions, and the detector receives the reflected light at an 8° angle from the surface of the object being measured. This is called "sphere geometry" because the instrument contains a sphere that provides diffuse illumination. In a sphere spectrophotometer, the inside of the sphere is lined with a highly reflective, low-gloss matte white material used to project and diffuse light, making it a near-perfect white reflector. When a beam of light strikes a point on the surface of the sphere, over 99% of the light is reflected. At the same time, the matte finish of the sphere causes the light to scatter randomly in all directions. This happens at every point on the surface and effectively makes the light inside the sphere appear to come from all directions simultaneously, making the inside of the sphere a light source.

Multi-Angle Spectrophotometer

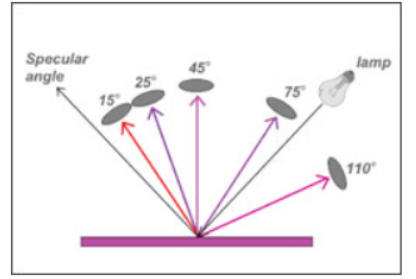

Multi-angle spectrophotometers view the color of a sample as if it were being moved back and forth, much like you would twist a sample to view the color at different angles. Today's multi-angle instruments are used for special coating pigments and special effect colors with additives such as mica and pearlescence, such as nail polish and automotive coatings. These are commonly used in labs, production lines, QC operations, and shipping areas.

Multi-angle is very complex and requires the user to verify five or more sets of L*a*b* values or Delta E* values. Their aperture size is typically 12 mm, which is too large to measure the fine details that occur in many small industrial applications. While the main illumination is typically provided at a 45° angle, some models provide auxiliary illumination at a 15° angle. The latest generation of multi-angle spectrophotometers features up to 12 measurement angles for comprehensive characterization and measurement of effect finishes in various applications, including automotive paints, plastics, and metals.

Spectrophotometers come in single-beam and double-beam configurations. A double-beam spectrophotometer compares the light intensity between two light paths, one containing a reference sample and the other containing a test sample. A single-beam spectrophotometer measures the relative light intensity of the beam before and after inserting the test sample.

Advantages of X-Rite Spectrophotometers

From cardboard packaging to laundry soap, carpets, and small plastic parts, X-Rite spectrophotometers help ensure that the color produced matches the color initially specified the first time, reducing waste and saving you time and money.

“We consider X-Rite to be a vital partner in our evolution and continued exceeding of customer expectations. Our past experiences with X-Rite and GretagMacBeth products have been excellent, and the new Ci7800 is no exception. Having this next-generation instrument as an integral part of our operations is critical to our ability to continue driving our color-critical business forward.”

Spectrophotometer Categories

As a global leader in color trends, science, and technology, we offer a full range of solutions from inspiration to final delivery, consistently and accurately controlling color. Whether you want to specify, communicate, formulate, and measure color, we help you make the right choice the first time, every time.

-

Portable Spectrophotometers

X-Rite portable devices are rugged, accurate, and comfortable to hold in your hand or pocket, allowing you to measure color anywhere in your operation. Browse solutions for a range of surface geometries and materials. -

Benchtop Spectrophotometers

X-Rite benchtop displays are the choice for lab operations that require the highest level of color accuracy and control.

Frequently Asked Questions about Spectrophotometers

Why use a spectrophotometer?

A spectrophotometer is a device used to measure and control color data. It is widely used in various industries to ensure color consistency throughout the entire process, from design to production. They can measure a variety of materials, from liquids and plastics to paper and fabrics.

Spectrophotometers identify color deviations and flaws through accurate color measurement, quantifying the difference between the produced color (sample) and the technical specifications. By collecting data from these instruments, trends for continuous improvement can be identified, ensuring compliance with standards such as ISO and ASTM.

Working Principle of a Spectrophotometer

Spectrophotometers measure reflected or transmitted light across the entire spectral range, generating a visual curve that describes the color on a specific substrate under specific lighting conditions.

A white surface reflects all light energy across the entire visible spectrum; therefore, its spectral reflectance curve is a straight line with a reflectance of approximately 90% to 100%. Black absorbs almost all light energy, so its reflectance curve is flat, with reflectance close to 0%. Intermediate grays are formed by combining equal proportions of white and black, and their reflectance curve is also a straight line, with a reflectance of 50%. The reflectance of other colors peaks in the wavelength range where they reflect the most light.

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Kaiyin Technology - Awarded "Specialized and New Enterprise"

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen municipal preliminary examination, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements. It marks another significant step forward for Kaiyin Technology in technological innovation and development in its specialized field.

MeasureColor and eXact AutoScan help you achieve exceptional print quality.

Achieving stable print quality hinges on your ability to control dot gain—a critical yet often overlooked variable. Dot gain significantly impacts color accuracy, image sharpness, and overall visual performance, particularly in packaging printing and workflows involving expanded color gamuts. With MeasureColor, printers can access advanced tools that enable them to effortlessly monitor, manage, and optimize dot gain in real time—eliminating the need for subjective guesswork.

On the journey toward higher precision, greater efficiency, and more sustainable development in the printing industry, the plate-making stage has always served as a crucial link—connecting the past with the future. As numerous printing companies choose among the dazzling array of CTP (Computer-to-Plate) equipment available, one well-known name—Kodak—often finds itself at the center of attention with its CTP solutions.

In manufacturing, even the slightest difference in color can often be the dividing line between high-quality and substandard products. Whether it’s apparel, building materials, cosmetics, or durable consumer goods, consistently accurate colors are not only a pursuit of product aesthetics—they also serve as the cornerstone of brand commitment and customer trust. Achieving this goal is inseparable from powerful color measurement tools—high-performance spectrophotometers.

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time