Say goodbye to color difference anxiety! X-Rite + GMG ensures your designs are delivered to clients in their original, true-to-life colors.

Release Time: 2025-04-15 00:00:00.000

“The client's sample draft had such beautiful colors, but the printed version looks like it has a gray filter applied?”—This is probably the most dreaded “epic fail” scenario for designers and printing plants. Color management sounds sophisticated, but the core concept is simple: “From screen to physical object, the colors shouldn't deviate.” Today, we'll discuss how to use X-Rite and GMG, two major “color protectors,” to ensure a “zero color difference” between the client's sample draft and the finished product!

I. Why are your colors always “running away”?

Color management is not esoteric, but it is a systematic process. For example:

- Equipment differences: Your monitor, printing press, and even lighting environment can all cause the same color code to “change its face.”

- Communication errors: The client says “high-class red,” but you understand it as “sorghum red”? Digital color standards are the hard currency.

- Process gaps: From design to printing, the lack of a unified color calibration tool is like dropping the baton in a relay race.

- This is where the X-Rite and GMG “golden partners” come in handy!

Pain Point Focus:

• Inconsistent colors between design drafts and finished products

• Difficult to control color differences between different batches and suppliers

• Lack of digital tools, reliance on subjective experience

II. X-Rite: From “inaccurate measurement” to “steady as an old driver”

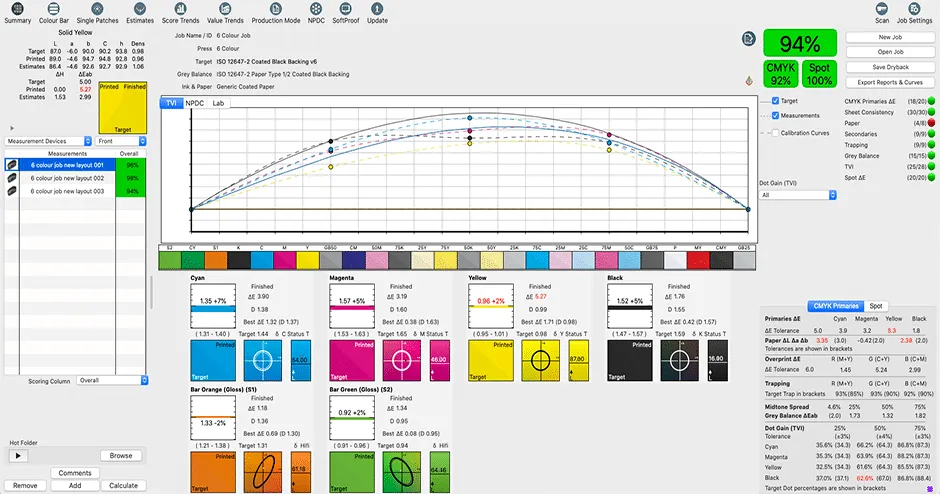

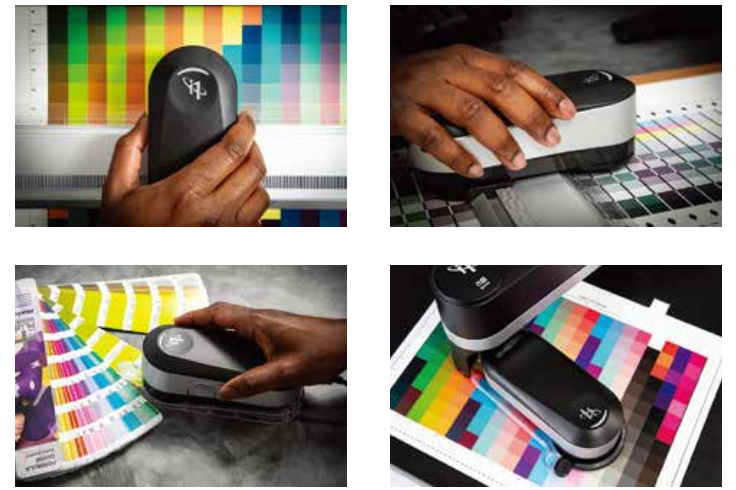

X-Rite can be considered a “Swiss Army knife” in the color world. Its strength lies in “turning colors into quantifiable data,” with three core tools:

1. Precise measurement: Spectrophotometer

X-Rite spectrophotometer: such as the eXact2 portable spectrophotometer, supports multiple colorimetric systems (Lab*, ∆Eab, etc.), can measure true color and surface color including specular reflection, analyze the influence of material and gloss on color, and has a repeatability error as low as 0.10∆Eab813.

Standard light source cabinet: such as the Judge QC color-matching light box, provides 5 light sources for visual assessment, including optional LEDs, for stable and consistent visual assessment.

Machine closed-loop correction + sample evaluation system: Through closed-loop control technology, automatic calibration of the printing press is achieved, reducing manual intervention and improving efficiency by more than 30%.

2. Color standard: ICC file

- X-Rite's equipment can generate the device's “color ID card” (ICC file), ensuring that the monitor, printing press, and scanner “speak the same color language.” For example, through linearization calibration and ICC embedding, the color gamut reproduction of digital printing presses is directly maximized.

3. Full process management: Software suite

- Color iQC: Automatically compares color tolerances, generates quality inspection reports, reduces arguments between clients and suppliers, and improves efficiency.

- i1Profiler: Supports high-definition screen calibration, so designers no longer have to worry about “display deviations” on Retina screens.

III. GMG: Making proofing “what you see is what you get”

Ensuring manufacturers, designers, and brands obtain the best measurement results

If X-Rite is the “color measurement expert,” GMG is the “color conversion master.” Its ColorProof software focuses on two major pain points:

Precise proofing

Directly connects to X-Rite's ICC files, simulates different printing conditions (such as paper and ink), and the similarity between the proofing effect and the finished product is as high as 98%.

Supports international standards (such as G7, ISO), and seamless color “interconnection” in the global supply chain.

Intelligent cost savings

Automatically optimizes ink usage, reduces waste, and is especially suitable for small batch orders.

The closed-loop control system adjusts printing parameters in real time, saving the time of repeated machine adjustments.

Case :After a packaging plant used the GMG + X-Rite solution, the customer complaint rate dropped by 70%, because “the proofing and finished products are placed together, even the boss can't tell them apart.”

IV. Practical skills: How to “train” client samples?

Step 1: Equipment calibration

Use X-Rite i1Pro3 to calibrate the monitor and printer to ensure that your screen is not a “photo-cheating device.”

Step 2: Generate color standards

Scan the client's sample draft and use X-Rite tools to create an ICC file, and then pass it to the GMG software to lock the color “DNA.”

Step 3: Simulation and verification

GMG simulates the printing effect, and uses a light source box to check the performance under different lighting conditions to avoid “beautiful in the sun, waste in the shade.”

V. Summary: Color management is not about burning money, it's about saving money!

A mature color solution may cause initial pain in terms of investment, but in the long run, reducing rework and avoiding reprinting due to color differences will save real money.

Improved reputation: A client's comment of “the color is accurate” is worth more than millions in advertising fees.

Cross-industry applicability: From pills to sports cars, from posters to tiles, the underlying logic is the same.

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Kaiyin Technology - Awarded "Specialized and New Enterprise"

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen municipal preliminary examination, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements. It marks another significant step forward for Kaiyin Technology in technological innovation and development in its specialized field.

“The colors in the sample provided by the client were gorgeous on screen, but the printed version looks like it has a grey filter applied?” - This is probably the worst nightmare for designers and printers. Color management sounds sophisticated, but the core concept is simple: “From screen to print, the colors must not deviate”. Today, we will discuss how to use X-Rite and GMG, two major “color protectors”, to ensure a perfect color match between the client's sample and the final product!

How to mix printing inks? IFM digital precise color matching system

Digital technologies are revolutionizing the printing industry. However, ink rooms are often overlooked when offset printing plants seek ways to improve quality, reduce costs, and increase productivity. This is undoubtedly a major misunderstanding, because if the offset printing ink is substandard, all standardization efforts in the printing workshop will be in vain.

Print Quality Control: Why It Matters and How to Manage It

Many printers are familiar with the print quality procedures required by some clients. For the brand, a print quality plan ensures that the printed materials meet its color requirements. Brand colors are important, and printed materials often directly represent the brand. Whether it's product labels, packaging, or brochures, print quality significantly impacts customer perception of the company. The reasons why print buyers implement print quality plans are print quality, brand color, and the complexity of achieving good print quality throughout the supply chain. While most people consider the brand when considering print quality plans, some printers also develop internal print quality plans. In all cases, the goal is the same: to ensure consistent and accurate printed products. The benefits for brands and printers are also similar - improved quality, reduced waste, increased efficiency, and saving time and money. For printers, the savings are faster turnaround times, less time, and less waste. For the brand, the benefits are brand integrity, less waste due to quality issues, and the assurance that the printer only delivers products that meet the agreed-upon requirements.

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time