Color Technology Sharing - To do a good job, you must first sharpen your tools

Release Time: 2022-11-30 18:48:09.670

Broadly speaking, color management refers to using certain methods to control the color of a product to achieve the target color; narrowly speaking, print color management refers to the management of the consistency of design, proofing, and production colors based on the standards set by the International Color Consortium (ICC), achieving color consistency on different display media. Color accuracy is a core element of printing production, and it is a consensus that various tools and systems are needed to control and manage color.

As printing companies whose main goal is color reproduction, they are actually all doing color management, but there are significant differences in the investment in color management and the final effect. A considerable number of companies attach great importance to color management; they purchase the most advanced color management tools, establish professional, comprehensive, and powerful color management teams, and possess international color management certifications, thus gaining the favor of high-end brand manufacturers and securing a large number of orders. However, some companies only have basic color management tools and basic professional color management personnel, only able to meet the color requirements of general customers.

Color management is of great significance.

From a technical perspective, color reproduction is a systematic project, using different color rendering principles, different substrates, different pigments, different production methods, and different post-processing processes; even under the same materials and processes, the color cannot naturally remain constant with changes in environment and time. Therefore, in order to achieve consistent and relatively constant color reproduction, repeated adjustments and management of color are necessary; otherwise, it will be out of control, failing to achieve the color target, resulting in waste, returns, and even compensation.

In a customer-centric market competition, the quality and quantity of business received by a company are directly affected by the quality of its color management. Customers expect printing companies to have complete color management tools and a perfect color management system, to be able to quickly submit samples that meet the requirements, and to maintain stable color production in the follow-up; otherwise, it will affect customer trust and confidence, leading to loss of orders.

People's demand for environmental protection is increasing, while the lack of color management will prolong the adjustment time, resulting in more waste products and waste materials. The increase in harmful materials will not only increase processing costs but also lead to more pollution. Good color management can quickly meet color requirements, reduce related waste, and thus reduce environmental pollution.

Four basic elements for achieving color management

1

Maintaining the stability of materials, equipment, and processes

Maintaining the stability of materials, equipment, and processes is the foundation for the normal and effective operation of color management. The reasons for unsuccessful color management are often due to the lack of standardization in the printing workshop. Relatively speaking, the screen calibration in the pre-press workshop and the digitalization of digital proofing are highly advanced, and CTP has made significant progress in stability compared to the previous film exposure, especially the application of process-free plates, which further enhances the stability of pre-press.

The standardization of the printing workshop needs to start from many aspects: training the theoretical knowledge of operators, letting them know why they need to do color management and what work they need to do; establishing a complete equipment maintenance system and strictly enforcing it; stabilizing various consumables (taking offset printing as an example, such as workshop temperature and humidity, dampening solution, rubber blanket, ink and water pressure, etc.), and not changing them without special circumstances; if changes are necessary, an assessment and retesting and curve adjustment are required; using instruments to measure the production process and strictly controlling it with data.

2

Complete color management tools are required.

Color digitization is the basis for good color management. Nowadays, color management tools are becoming more and more automated, intelligent, and standardized. For different materials and processes, appropriate tools and solutions need to be selected.

3

Follow standards and obtain relevant certifications.

The standards for printing color management are relatively comprehensive and complete, covering all stages from pre-press design and plate making to printing, and also including different printing methods such as offset printing and flexographic printing. In order to implement these standards and meet the strict requirements of international brand manufacturers, printing standard certification is very necessary. Currently, G7, PSA, GMI, and PSO are relatively mainstream certification processes.

4

Professional personnel and organizational development

Having good equipment, materials, and tools is not enough; the establishment of factory standards and processes requires selection and creation based on the actual situation, which requires professional technical personnel and management personnel to form a relatively complete organization to establish them.

How to obtain high-level

Color accuracy and data integrity

Current printing materials and effects are becoming increasingly complex, posing challenges to accurate measurement. To obtain high-level color accuracy and data integrity, we can start from the following two aspects:

1

Select appropriate measurement tools

For different substrates, the structure of the measuring instrument should be different. Ordinary paper printing can use a 45°/0° structure eXact instrument for detection and control; however, for gold and silver card paper printing, an integrating sphere spectrophotometer should be selected for measurement; for gold, silver, pearlescent, and other special effect inks, a multi-angle spectrophotometer should be used for measurement; otherwise, the data will not be able to accurately and completely represent the appearance characteristics of the product, nor will it be able to obtain results consistent with visual observation.

Color bars are universally recognized elements for the detection and control of color information in the industry. They contain various color information, such as density, chromaticity, dot gain, trapping, neutral gray, etc. By measuring and controlling the color bars, the color of the entire sheet can be comprehensively controlled. Nowadays, many packages use spot colors; large areas of spot colors can be measured directly, while some small areas of spot colors need to add measurement color blocks to achieve digitized control.

In addition, the accuracy and status of the tools will change over time, affecting the reliability of the data. Therefore, it is necessary to regularly maintain, calibrate, and standardize them according to the manufacturer's recommendations and the company's own needs to ensure accurate data.

2

Conduct professional technical training

Employees need to receive sufficient training to master the skills of correctly using hardware and software, so that they can use them correctly, correctly interpret the measurement results, and make timely and correct responses. At the same time, visual assessment is still a very important method; after all, the final product is placed on the shelves for consumers to choose, and the data is obtained under very specific conditions, so visual assessment of color is still very necessary. Standard light sources, appropriate environments, reasonable sample placement, and eyes that have undergone evaluation and certification are all very important.

With increasingly fierce market competition, as well as the shortage of human resources and the increase in labor costs, companies are facing more and more challenges in their operations. To overcome difficulties and achieve differentiated competition, some customers have upgraded their color management systems from the following aspects to meet the needs of the new era:

First, improve the level of automated color measurement. Traditional manual single-point measurement is time-consuming and laborious, and the accuracy is also low, unable to meet the needs of rapid response. The upgraded automatic scanning measurement system IntelliTrax2 can scan an entire color bar in a few seconds, thus quickly obtaining a large amount of real data for subsequent analysis and adjustment.

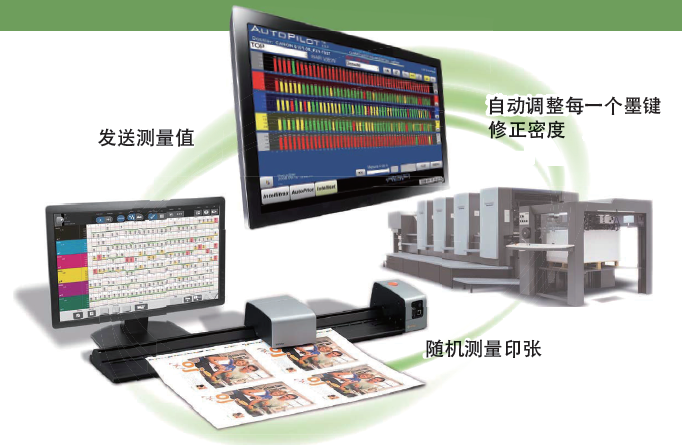

Secondly, it enhances the intelligent control of color. During the formula development stage, customers use the IFS6 ink color matching system to intelligently calculate the color formulas of various special colors, quickly and accurately preparing the special colors required by customers. During the production stage, customers install a closed-loop color management system, receive measurement data from the automatic scanning and measurement system, compare it with the color target for relevant calculations, and automatically send the ink amount adjustment information to the printing press for ink key adjustment, so that the required color can be quickly printed.

Product color data is also the company's digital assets. How these assets are properly preserved and utilized effectively is also very challenging. Using professional software to record and regularly organize measurement data can effectively protect these digital assets; professional analysis can obtain relevant insights, which can be used to improve future products and processes. Network and cloud-based applications can also effectively save data and easily share it between different departments or factories to maximize efficiency.

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Kaiyin Technology - Awarded "Specialized and New Enterprise"

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen municipal preliminary examination, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements. It marks another significant step forward for Kaiyin Technology in technological innovation and development in its specialized field.

MeasureColor and eXact AutoScan help you achieve exceptional print quality.

Achieving stable print quality hinges on your ability to control dot gain—a critical yet often overlooked variable. Dot gain significantly impacts color accuracy, image sharpness, and overall visual performance, particularly in packaging printing and workflows involving expanded color gamuts. With MeasureColor, printers can access advanced tools that enable them to effortlessly monitor, manage, and optimize dot gain in real time—eliminating the need for subjective guesswork.

On the journey toward higher precision, greater efficiency, and more sustainable development in the printing industry, the plate-making stage has always served as a crucial link—connecting the past with the future. As numerous printing companies choose among the dazzling array of CTP (Computer-to-Plate) equipment available, one well-known name—Kodak—often finds itself at the center of attention with its CTP solutions.

In manufacturing, even the slightest difference in color can often be the dividing line between high-quality and substandard products. Whether it’s apparel, building materials, cosmetics, or durable consumer goods, consistently accurate colors are not only a pursuit of product aesthetics—they also serve as the cornerstone of brand commitment and customer trust. Achieving this goal is inseparable from powerful color measurement tools—high-performance spectrophotometers.

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time