The importance of ultraviolet-visible spectrophotometers!

Release Time: 2025-03-15 00:00:00.000

To create eye-catching products, companies use Optical Brightening Agents (OBAs), also known as Fluorescent Whitening Agents (FWAs), to make their products appear brighter and whiter.

While adding OBAs can create brighter products, adding these chemicals fundamentally alters how color is perceived, making accurate color assessment by eye impossible. Under factory lighting, materials and fabrics containing OBAs may appear similar in production, but these same goods may look vastly different under other lighting conditions (such as retail LEDs, daylight, or household incandescent lighting). Anyone responsible for assessing goods containing UV-brightening agents needs a UV spectrophotometer and light booth to quantify how OBAs affect color appearance under different light sources.

What is Ultraviolet (UV) Light?

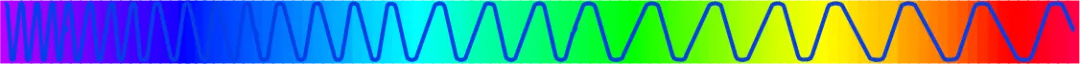

Let's go back to elementary school science class. This is the visible light spectrum – the light we see with our eyes – and it's just a small portion of the electromagnetic spectrum.

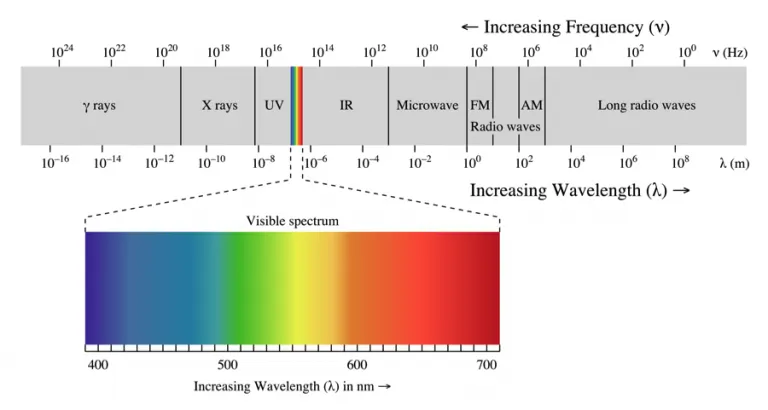

This is the electromagnetic spectrum. It starts with gamma rays on the far left, then moves right through X-rays, microwaves, and radio waves. The tiny visible light spectrum between ultraviolet and infrared light is the only part humans can see with the naked eye, unless OBAs are involved.

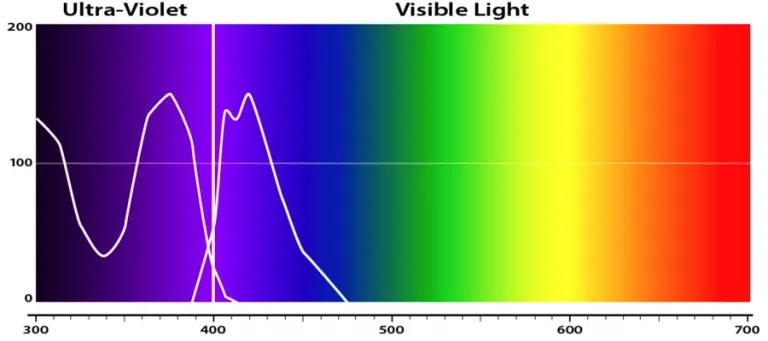

OBAs absorb a portion of invisible UV light and re-emit it as blue light. This reflected blue light makes fabrics appear brighter and whiter.

The right side of this graphic shows visible wavelengths, and the left side shows the UV region. Optical brightening agents work by absorbing these UV rays and emitting them into the visible spectrum for the human eye.

What is a UV Spectrophotometer?

Spectrophotometers quantitatively measure the amount of UV and visible light absorbed by a sample, allowing for the assessment of color consistency in products containing OBAs. These devices provide calibrated UV to measure and quantify this effect.

X-Rite UV Portable Spectrophotometers

The Ci64UV handheld sphere spectrophotometer features UV LED illumination to accurately quantify fluorescent whitening agents in plastics, textiles, and paper.

Ci64UV spectrophotometer measuring white plastic to assess the effect of optical brightening agents

Ci64UV spectrophotometer measuring white plastic to assess the effect of optical brightening agents

X-Rite UV Benchtop Spectrophotometers

X-Rite’s Ci7820, Ci7800, and Ci7600 sphere benchtops offer UV illumination to quantify the effects of optical brightening agents on a variety of opaque and translucent samples.

X-Rite UV Inline Spectrophotometers

The ColorXRA 45 is a compact UV-calibrated 45°/0° inline non-contact spectrophotometer. It can be mounted above paper and plastic production lines to identify color variations early and throughout the production process.

Assessing OBAs Using a Light Booth

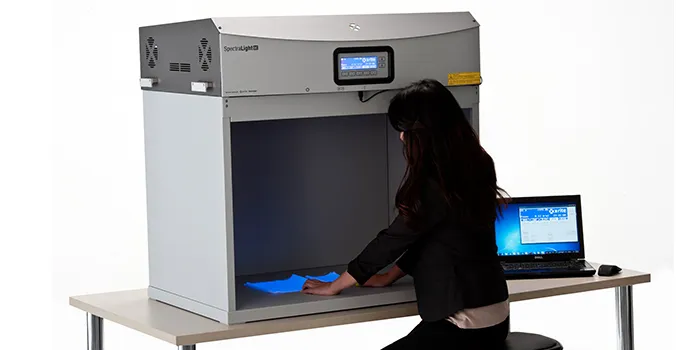

Optically brightened items can also be visually inspected under controlled UV lighting, such as that provided by the X-Rite SpectraLight QC light booth. Under UV light sources, items with higher OBA content will appear brighter, while items with less OBA will appear darker. The challenge is that you need a certain amount of UV to quantify the amount of OBA in a product. This means that when UV is low or absent, the color difference may be invisible. But when it is present, the color difference becomes very apparent.

Assessing white fabric samples containing optical brightening agents under UV light in the SpectraLight QC light booth

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Kaiyin Technology - Awarded "Specialized and New Enterprise"

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen municipal preliminary examination, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements. It marks another significant step forward for Kaiyin Technology in technological innovation and development in its specialized field.

“The colors in the sample provided by the client were gorgeous on screen, but the printed version looks like it has a grey filter applied?” - This is probably the worst nightmare for designers and printers. Color management sounds sophisticated, but the core concept is simple: “From screen to print, the colors must not deviate”. Today, we will discuss how to use X-Rite and GMG, two major “color protectors”, to ensure a perfect color match between the client's sample and the final product!

How to mix printing inks? IFM digital precise color matching system

Digital technologies are revolutionizing the printing industry. However, ink rooms are often overlooked when offset printing plants seek ways to improve quality, reduce costs, and increase productivity. This is undoubtedly a major misunderstanding, because if the offset printing ink is substandard, all standardization efforts in the printing workshop will be in vain.

Print Quality Control: Why It Matters and How to Manage It

Many printers are familiar with the print quality procedures required by some clients. For the brand, a print quality plan ensures that the printed materials meet its color requirements. Brand colors are important, and printed materials often directly represent the brand. Whether it's product labels, packaging, or brochures, print quality significantly impacts customer perception of the company. The reasons why print buyers implement print quality plans are print quality, brand color, and the complexity of achieving good print quality throughout the supply chain. While most people consider the brand when considering print quality plans, some printers also develop internal print quality plans. In all cases, the goal is the same: to ensure consistent and accurate printed products. The benefits for brands and printers are also similar - improved quality, reduced waste, increased efficiency, and saving time and money. For printers, the savings are faster turnaround times, less time, and less waste. For the brand, the benefits are brand integrity, less waste due to quality issues, and the assurance that the printer only delivers products that meet the agreed-upon requirements.

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time