Achieving spot color replacement and extended color gamut using fixed inks

Release Time: 2025-03-07 00:00:00.000

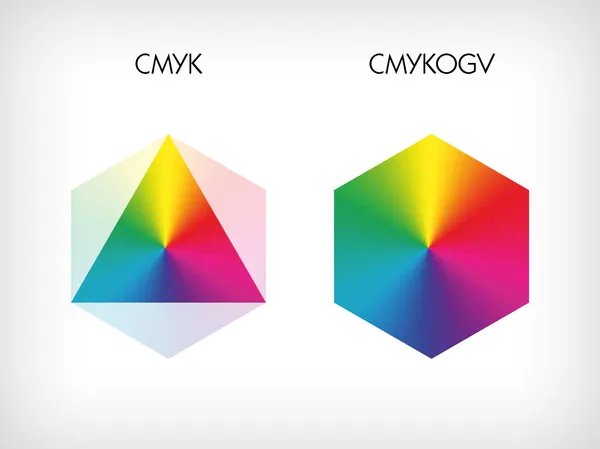

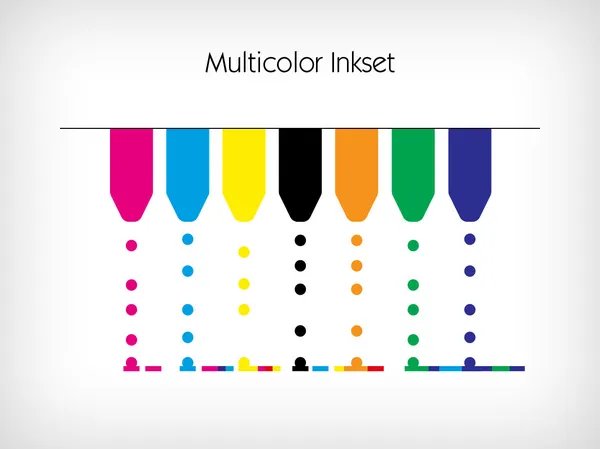

Before delving into the concept, let's understand what multicolor ink sets are. Multicolor ink sets refer to using more inks in the printing process than the traditional four-color (Cyan C, Magenta M, Yellow Y, Black K) process. It typically involves adding one or more specific color inks, such as Green G, Orange O, or Violet V, to the standard CMYK four-color inks. This extended gamut printing method expands the printing gamut, resulting in richer and more accurate color reproduction, better matching spot colors, and ultimately improving the color quality and visual effect of printed materials.

Clients demand faster and more flexible production schedules. This trend will continue due to the possibilities of digital prepress. The concept of fixed multicolor ink sets is compelling throughout the printing process—offering significant advantages not only in digital printing but also in offset, flexographic, gravure, and other printing methods. Compared to spot color printing, the Multicolor workflow significantly shortens print preparation time through additional printing colors and expands the color space, noticeably improving the quality of results.

Without a reliable color management process, digital printing is difficult to control.

The possibilities of digital printing are immense. There's only one problem: even the newest machines will surprise you with their printing results. Digital printing lacks industry standards; in reality, standard digital printing equipment can only take you so far. Prepress is crucial for achieving predictable results in digital printing. - Manual intervention on the printing press is only possible to a very limited extent.

If you expect accurate brand colors, you'll love Multicolor.

In packaging printing, spot colors are often used to accurately display a brand's product line. But in digital printing, where only a fixed set of colors is available, how can accurate brand colors be achieved using digital printing?

- Precise spot color reproduction – without compromising accuracy, with greater flexibility and efficiency.

- From customer data to target printing process – automatic conversion of spot colors with a single click.

- Complete control – reliable results, user-friendly application, and efficient processes.

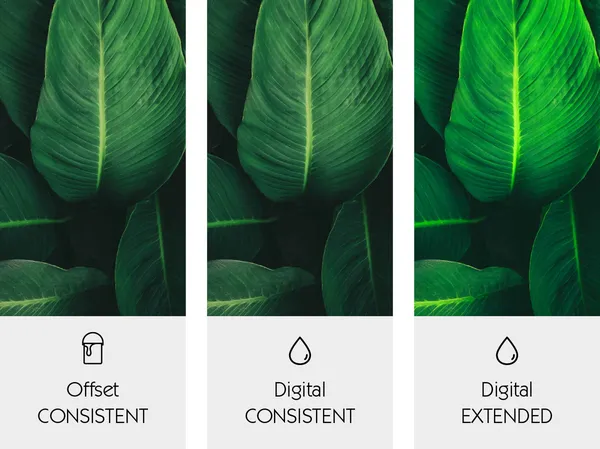

Achieve accurate cross-process results with Multicolor.

Cyan, magenta, yellow, and black, plus orange, green, and violet: Multicolor enables you to consistently achieve the results your clients desire:

- Consistent results – when digital printing results perfectly match traditional printing results.

- Brilliant colors – achieve more impressive print results using the expanded color space.

- Identical reprints – now, print jobs can be reprinted on different printing presses and with different printing processes with exactly the same quality.

GMG's Multicolor solution at a glance.

Consistent Results Brilliant Colors Spot Colors Identical Quality

Traditional printing fully leverages the expanded color space to achieve higher flexibility and efficiency. Reprint jobs anytime. Matched digital printing. Maintain the same quality in various printing processes.

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Kaiyin Technology - Awarded "Specialized and New Enterprise"

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen municipal preliminary examination, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements. It marks another significant step forward for Kaiyin Technology in technological innovation and development in its specialized field.

“The colors in the sample provided by the client were gorgeous on screen, but the printed version looks like it has a grey filter applied?” - This is probably the worst nightmare for designers and printers. Color management sounds sophisticated, but the core concept is simple: “From screen to print, the colors must not deviate”. Today, we will discuss how to use X-Rite and GMG, two major “color protectors”, to ensure a perfect color match between the client's sample and the final product!

How to mix printing inks? IFM digital precise color matching system

Digital technologies are revolutionizing the printing industry. However, ink rooms are often overlooked when offset printing plants seek ways to improve quality, reduce costs, and increase productivity. This is undoubtedly a major misunderstanding, because if the offset printing ink is substandard, all standardization efforts in the printing workshop will be in vain.

Print Quality Control: Why It Matters and How to Manage It

Many printers are familiar with the print quality procedures required by some clients. For the brand, a print quality plan ensures that the printed materials meet its color requirements. Brand colors are important, and printed materials often directly represent the brand. Whether it's product labels, packaging, or brochures, print quality significantly impacts customer perception of the company. The reasons why print buyers implement print quality plans are print quality, brand color, and the complexity of achieving good print quality throughout the supply chain. While most people consider the brand when considering print quality plans, some printers also develop internal print quality plans. In all cases, the goal is the same: to ensure consistent and accurate printed products. The benefits for brands and printers are also similar - improved quality, reduced waste, increased efficiency, and saving time and money. For printers, the savings are faster turnaround times, less time, and less waste. For the brand, the benefits are brand integrity, less waste due to quality issues, and the assurance that the printer only delivers products that meet the agreed-upon requirements.

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time