Unveiling GMG Color Management: How to Make Every Color "Obey"?

Release Time: 2025-03-06 00:00:00.000

Today, let's discuss a topic that seems professional yet full of "magic"—color management. Whether it's a designer's computer screen, a sample from a proofing center, a printed product from a printing plant, or a package on a supermarket shelf, color consistency is always a headache. GMG (a German color management giant), the star of today's discussion, acts like a "color translator," ensuring seamless color communication between different devices!

I. GMG's "Core Technology": Preventing Colors from "Changing Face"

1. Four-Dimensional Color Conversion Engine

GMG's ColorServer module has a "unique skill"—it directly converts from RGB or CMYK in four dimensions (e.g., CMYK→CMYK). Unlike traditional ICC profile files, it can independently handle the black channel, avoiding "color bleeding" issues during color mixing. This means that the black text in printed materials is sharper, and the dark areas have richer layers.

2. Closed-Loop Calibrated Digital Proofing System

GMG's ColorProof software allows printers to "self-correct." Using measuring instruments, it automatically scans printed samples and adjusts parameters to ensure consistent output from each device (e.g., EPSON, HP, Roland large-format printers). In short, it makes the printer "look in the mirror" and adjust itself to its optimal state.

3. High-Fidelity Spot Colors

Spot colors such as gold and fluorescent colors commonly used in packaging printing are difficult to simulate with traditional digital proofing. GMG's InkOptimizer, through a multi-color ink combination algorithm, can even simulate metallic luster effects. For example, COFCO Meite's metal can printing relies on it to achieve accurate spot color reproduction.

II. GMG's "Workflow Magic": From Design to Printing, All in One Step

Imagine: a designer adjusts a poster on their computer and sends it directly to the factory, with the colors perfectly matched—this is the networked color workflow built by GMG.

- Designer's End: ColorServer automatically converts RGB images to CMYK for printing, while retaining highlight and shadow details, avoiding the "dull" effect.

- Printing Plant's End: ColorProof generates contract-level digital proofs, and the InkOptimizer module optimizes ink usage, reducing waste by 15%-30% (environmentally friendly and cost-effective).

- Quality Control Stage: The ProofControl tool automatically detects color differences in samples, generates reports, and even the boss can understand where rework is needed.

III. Practical Cases: How "Hardcore" Can Color Management Be?

Application Cases in Metal Packaging Printing

COFCO Meite, a leading Chinese company in the metal packaging industry, produces products including beverage cans, milk powder cans, and food cans, with extremely high requirements for color accuracy and spot color simulation. The application of GMG color management software at COFCO Meite mainly includes:

- High-Fidelity Printing and Spot Color Simulation: Through GMG solutions, COFCO Meite has achieved accurate simulation of spot color printing, meeting customer needs for consistent brand visuals. For example, in transfer printing and tin printing processes, GMG ensures high matching between spot colors and four-color printing.

- Color Uniformity Across Multiple Production Lines: GMG helps COFCO Meite achieve color standardization across different printing production lines, solving the color difference problems caused by equipment differences in traditional printing and improving production efficiency.

Application Cases in the Digital Printing Industry

Beijing Shengtong introduced HP Indigo 750 digital printing equipment and combined it with GMG color management software, significantly improving the color stability of digital printing:

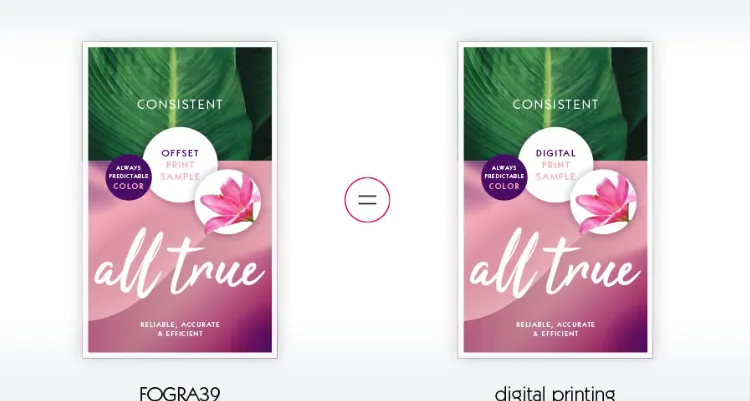

- Offset Paper Color Optimization: By calibrating 120g offset paper with GMG, the color difference between samples before and after using GMG was minimized, verifying the efficiency of GMG in digital printing.

- Fast Proofing and Cost Control: GMG's closed-loop correction technology shortens the proofing cycle and reduces material waste before printing, especially suitable for short-run printing orders.

Technical Certification and Industry Recognition

GMG solutions have passed multiple international technical certifications, including Fogra and PSO, and have accumulated more than 120 international brand application cases worldwide. Remote proofing and cross-regional collaboration are used by multinational printing groups for multi-location collaborative production.

So, after reading the above, you finally understand why GMG can accurately control every inch of color, right?

Some of the pictures and texts in this site are collected and collated from the network for learning and exchange only. The copyright belongs to the original author. If you have violated your rights, please contact us to delete them in time.

More News

Kaiyin Technology - Awarded "Specialized and New Enterprise"

Kaiyin Technology, with its professional R&D and service teams, sound management system, and excellent innovation mechanism, successfully passed the enterprise self-assessment, Shenzhen municipal preliminary examination, and national ministry review procedures, ultimately winning multiple honorary titles including "Specialized and New Enterprise," "High-tech Enterprise," and "Innovative Small and Medium-sized Enterprise." The acquisition of these honors is a high recognition of Kaiyin Technology's innovation capabilities, technological R&D strength, and industry specialization, and further affirmation of the company's innovative development achievements. It marks another significant step forward for Kaiyin Technology in technological innovation and development in its specialized field.

“The colors in the sample provided by the client were gorgeous on screen, but the printed version looks like it has a grey filter applied?” - This is probably the worst nightmare for designers and printers. Color management sounds sophisticated, but the core concept is simple: “From screen to print, the colors must not deviate”. Today, we will discuss how to use X-Rite and GMG, two major “color protectors”, to ensure a perfect color match between the client's sample and the final product!

How to mix printing inks? IFM digital precise color matching system

Digital technologies are revolutionizing the printing industry. However, ink rooms are often overlooked when offset printing plants seek ways to improve quality, reduce costs, and increase productivity. This is undoubtedly a major misunderstanding, because if the offset printing ink is substandard, all standardization efforts in the printing workshop will be in vain.

Print Quality Control: Why It Matters and How to Manage It

Many printers are familiar with the print quality procedures required by some clients. For the brand, a print quality plan ensures that the printed materials meet its color requirements. Brand colors are important, and printed materials often directly represent the brand. Whether it's product labels, packaging, or brochures, print quality significantly impacts customer perception of the company. The reasons why print buyers implement print quality plans are print quality, brand color, and the complexity of achieving good print quality throughout the supply chain. While most people consider the brand when considering print quality plans, some printers also develop internal print quality plans. In all cases, the goal is the same: to ensure consistent and accurate printed products. The benefits for brands and printers are also similar - improved quality, reduced waste, increased efficiency, and saving time and money. For printers, the savings are faster turnaround times, less time, and less waste. For the brand, the benefits are brand integrity, less waste due to quality issues, and the assurance that the printer only delivers products that meet the agreed-upon requirements.

Service Hotline:

180 8888 0185

Address:

605, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Tel:

Fax:

Email:

Copyright ©Shenzhen Kaiyin Technology Co., Ltd 粤ICP备16126578号 SEO

Website support:300.cn ShenZhen

Mobile: 180 8888 0185

Tel: +86 755 8280 8180

Address: 305A, Floor 3, Building B1, Funian Plaza, No. 3, Shihua Road, Futian District, Shenzhen, Guangdong

Email: service@kngcolor.com

We will give you feedback in time